A low-nitrogen combustion system for a regenerative heating furnace and its working method

A low-nitrogen combustion and heating furnace technology, applied in the field of heating furnace combustion, can solve the problems of ineffective recycling, high NOx emissions, and small firepower, so as to avoid local high temperature of the flame, save energy, and reduce heat loss rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

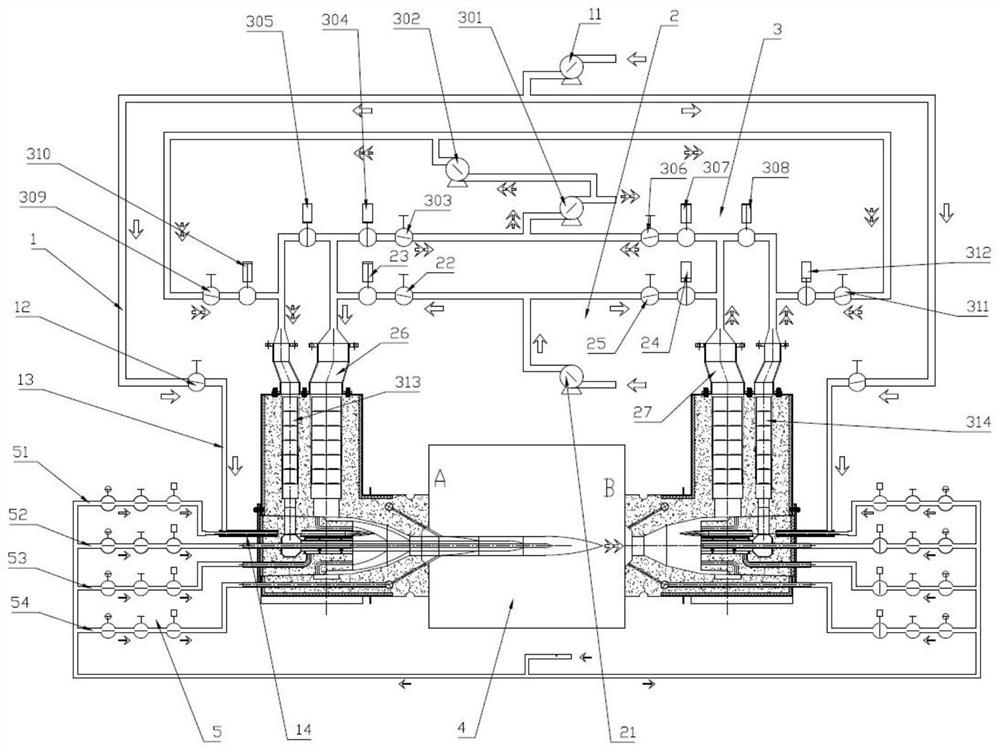

[0040] see figure 1 , the low-nitrogen combustion system of the regenerative heating furnace in this embodiment includes the furnace 4 and the burners A and B on both sides of the furnace 4. The A and the burners are double regenerators, respectively, and the flue gas The regenerator and the air regenerator, and the flue gas regenerator is located behind the air regenerator, away from the side of the furnace 4, and plays the role of thermal insulation for the burner box, so that the burner box surface temperature Reduced, with energy-saving effect. In addition, the system also includes an ignition system 1 , an air supply system 2 , a flue gas circulation system 3 and a gas supply system 5 .

[0041] The ignition system 1 includes a high-pressure vortex air pump 11, a first manual regulating valve 12, an air supply pipeline 13 and an ignition pipeline 14. One end of the air supply pipeline 13 is connected to the high-pressure vortex air pump 11, and the other end is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com