Growth process method of large-diameter high-purity semi-insulating silicon carbide

A process method and semi-insulating technology, which are applied in the field of large-diameter high-purity semi-insulating silicon carbide growth, can solve the problems affecting the yield and technical indicators of the substrate, and the low utilization rate of raw materials, so as to achieve a low nitrogen content and improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

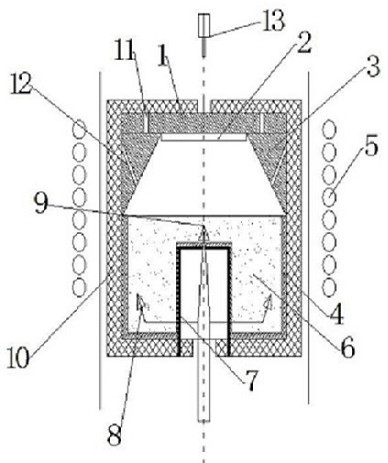

[0058] Embodiment 1. Large-diameter high-purity semi-insulating silicon carbide growth process

[0059] Using the thermal field of the dual heating structure and the bottom diffusion structure of the present application, the PVT method is used to grow a high-purity semi-insulating silicon carbide single crystal, and the specific steps are as follows:

[0060] 1. Place the high-purity silicon carbide raw material in the graphite crucible, and the upper part of the crucible is assembled as follows figure 1 The structure of seed holder, 2 seeds, and 3 expansion rings. The exterior is wound with a thermal insulation layer according to the process design. Material selection graphite carbon fiber. The above assembly is called the growth thermal field, and all the graphite materials are high-purity graphite materials, and the purity requirement is <5ppm purified graphite.

[0061] 2. Place the assembly growth heat field completed in step 1 in a single crystal growth furnace, and e...

Embodiment 2

[0070] Embodiment 2. Large-diameter high-purity semi-insulating silicon carbide growth process

[0071] Using the thermal field of the dual heating structure and the bottom diffusion structure of the present application, the PVT method is used to grow a high-purity semi-insulating silicon carbide single crystal, and the specific steps are as follows:

[0072] 1. Place the high-purity silicon carbide raw material in the graphite crucible, and the upper part of the crucible is assembled as follows figure 1 The structure of seed holder, 2 seeds, and 3 expansion rings. The exterior is wound with a thermal insulation layer according to the process design. Material selection graphite carbon fiber. The above assembly is called the growth thermal field, and all the graphite materials are high-purity graphite materials, and the purity requirement is <5ppm purified graphite.

[0073] 2. Place the assembly growth heat field completed in step 1 in a single crystal growth furnace, and e...

Embodiment 3

[0082] Embodiment 3. Large-diameter high-purity semi-insulating silicon carbide growth process

[0083] Using the thermal field of the dual heating structure and the bottom diffusion structure of the present application, the PVT method is used to grow a high-purity semi-insulating silicon carbide single crystal, and the specific steps are as follows:

[0084] 1. Place the high-purity silicon carbide raw material in the graphite crucible, and the upper part of the crucible is assembled as follows figure 1 The structure of seed holder, 2 seeds, and 3 expansion rings. The exterior is wound with a thermal insulation layer according to the process design. Material selection graphite carbon fiber. The above assembly is called the growth thermal field, and all the graphite materials are high-purity graphite materials, and the purity requirement is <5ppm purified graphite.

[0085] 2. Place the assembly growth heat field completed in step 1 in a single crystal growth furnace, and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com