ZK60 magnesium alloy preparation method based on SPS technology

A magnesium alloy technology, applied in the field of ZK60 magnesium alloy preparation based on SPS technology, can solve problems such as poor density and uneven structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of ZK60 magnesium alloy preparation method based on SPS technology, comprises the following steps:

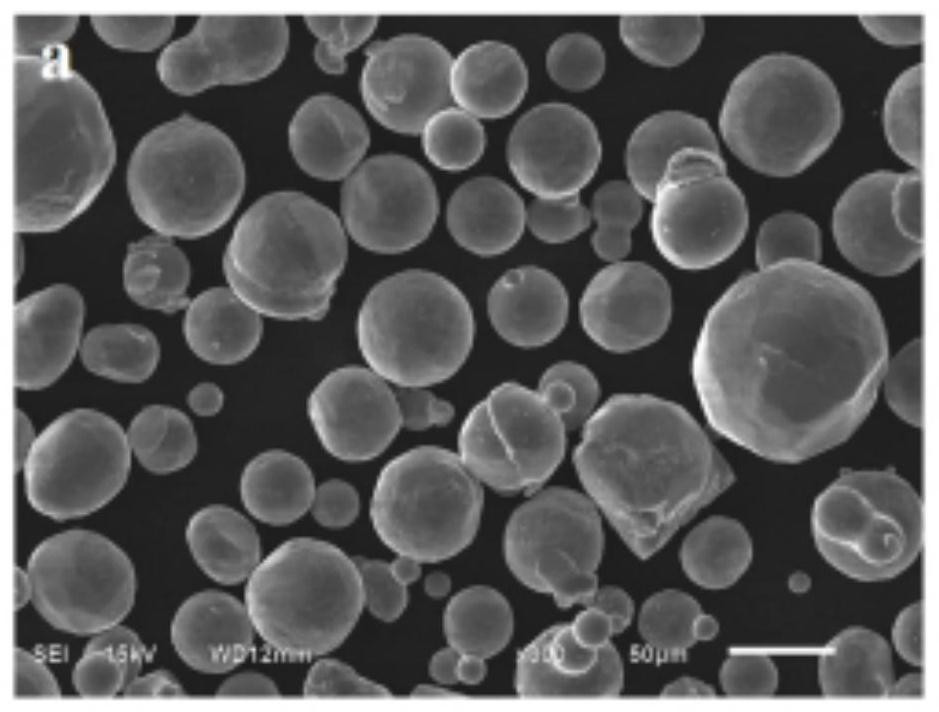

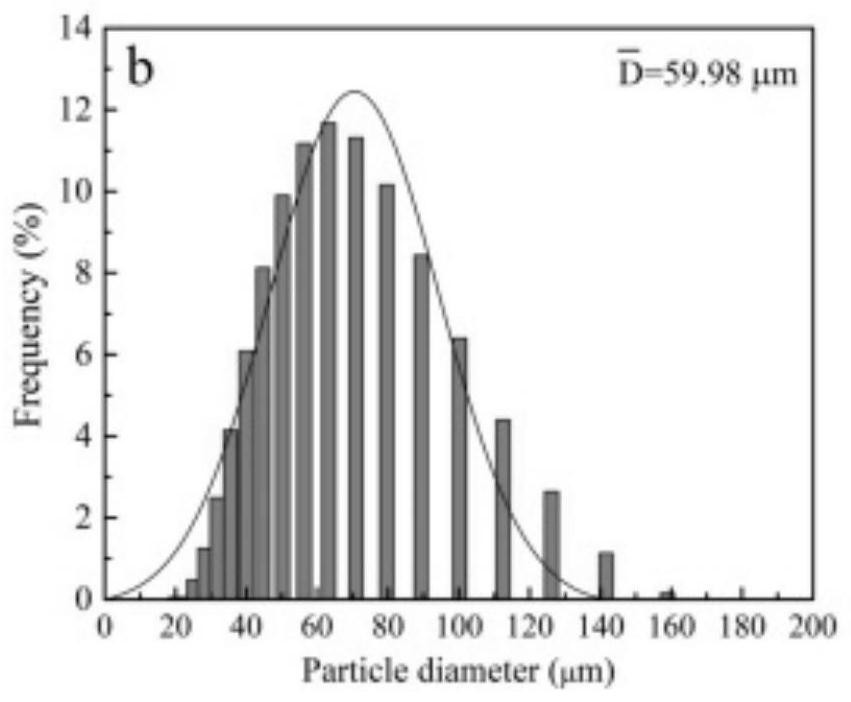

[0033] S1, the ZK60 magnesium alloy powder of Mg-Zn-Zr ternary system alloy is poured in the stainless steel ball mill tank, and to wherein adding dehydrated alcohol (analytical pure) carries out ball milling, the mass ratio of ZK60 magnesium alloy powder and dehydrated alcohol= 2.63:1; ball milling parameters are: ball to material ratio is 3:1, ball milling speed is 200rpm, ball milling time is 2h;

[0034] S2, the powder after ball milling is vacuum-dried, and the vacuum-drying condition is: 10 -2 Below Pa;

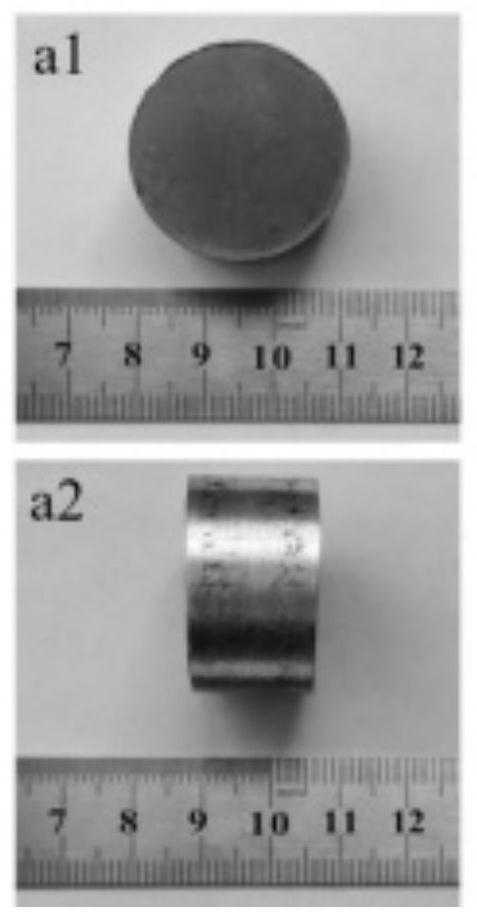

[0035] S3. Put the vacuum-dried powder in a grinding tool with a diameter of 30mm, and sinter it in the SPS discharge plasma sintering equipment of LABOX-325R. The pressure is 3500kg, and the temperature is kept for 10 minutes under the protection of Ar gas to obtain the sintered ZK60 magnesium alloy material.

[0036] Wherein the contents of Mg, Zn, and...

Embodiment 2

[0038] S1, the ZK60 magnesium alloy powder of Mg-Zn-Zr ternary system alloy is poured in the stainless steel ball mill tank, and to wherein adding dehydrated alcohol (analytical pure) carries out ball milling, the mass ratio of ZK60 magnesium alloy powder and dehydrated alcohol= 2.63:1; ball milling parameters are: ball to material ratio is 3:1, ball milling speed is 200rpm, ball milling time is 2h;

[0039] S2, the powder after ball milling is vacuum-dried, and the vacuum-drying condition is: 10 -2 Below Pa;

[0040] S3. Put the vacuum-dried powder in a grinding tool with a diameter of 30mm, and sinter it in the SPS discharge plasma sintering equipment of LABOX-325R. The pressure is 3500kg, and the temperature is kept for 10 minutes under the protection of Ar gas to obtain the sintered ZK60 magnesium alloy material.

[0041] Wherein the contents of Mg, Zn, and Zr in the ZK60 magnesium alloy in step S1 are 93.5%, 6%, and 0.5%, respectively.

Embodiment 3

[0043] S1, the ZK60 magnesium alloy powder of Mg-Zn-Zr ternary system alloy is poured in the stainless steel ball mill tank, and to wherein adding dehydrated alcohol (analytical pure) carries out ball milling, the mass ratio of ZK60 magnesium alloy powder and dehydrated alcohol= 2.63:1; ball milling parameters are: ball to material ratio is 3:1, ball milling speed is 200rpm, ball milling time is 2h;

[0044] S2, the powder after ball milling is vacuum-dried, and the vacuum-drying condition is: 10 -2 Below Pa;

[0045] S3. Put the vacuum-dried powder in a grinding tool with a diameter of 30mm, and sinter it in the SPS discharge plasma sintering equipment of LABOX-325R, and raise the temperature to 450°C at a heating rate of 100°C / min. The pressure is 3500kg, and the temperature is kept for 10 minutes under the protection of Ar gas to obtain the sintered ZK60 magnesium alloy material.

[0046] Wherein the contents of Mg, Zn, and Zr in the ZK60 magnesium alloy in step S1 are 93...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com