ZK61M magnesium alloy for aerospace

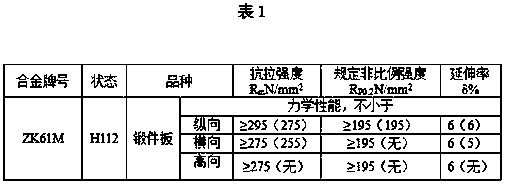

A ZK61M, aerospace technology, applied in the field of alloy manufacturing, can solve the problems that the non-proportional strength is difficult to achieve, and the tensile strength of high-directional performance is difficult to achieve, so as to achieve the effect of ensuring three-dimensional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of ZK61M magnesium alloy for aerospace, it is prepared through the following steps:

[0020] (1) Forging: Heating and forging the ZK61M round ingot conforming to the YS / T 627-2013 wrought magnesium and magnesium alloy round ingot standard, the heating temperature is 420-430°C, and the heating time is 13-16 hours. Forging in the three directions of length, width and height, the final forging temperature is not less than 350°C to obtain a forged plate; the forging ratio of 10-20 is preferably used for forging in the three directions of length, width and height. An optional ZK61M round ingot size is Φ300-500mm in diameter and 600-700mm in length. When forging, the round ingot with a length of 600-700mm is first forged to 300-400mm, and then forged into a rectangle, and then the length is , width, and height are forged in three directions, and finally forged into a forged plate with a thickness of 150-155mm;

[0021] (2) Hot rolling: heat the forged plate obtained i...

Embodiment 2

[0025] A kind of ZK61M magnesium alloy for aerospace, it is prepared through the following steps:

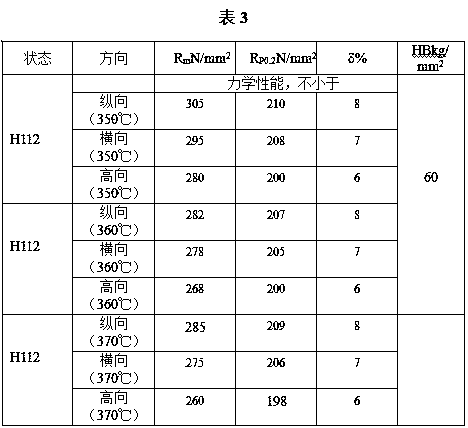

[0026] (1) Forging: The ZK61M round ingot conforming to the YS / T 627-2013 wrought magnesium and magnesium alloy round ingot standard is heated and forged. The size of the round ingot is Φ450mm in diameter, 700mm in length, and the heating temperature is 420°C. The heating time is 16 hours. When forging, the round ingot with a length of 700mm is first forged to 400mm, and then forged into a rectangle, and then forged with a forging ratio of 15 in the three directions of length, width and height. The final forging temperature is 350 ℃, and finally forged into a 150mm thick forged plate; samples were taken from the 150mm thick plate, and the mechanical properties at room temperature are shown in Table 2 (three test data).

[0027]

[0028] It can be seen from Table 2 that the tensile strength and non-proportional strength of the magnesium alloy after forging do not meet the requ...

Embodiment 3

[0038] A kind of ZK61M magnesium alloy for aerospace, it is prepared through the following steps:

[0039](1) Forging: The ZK61M round ingot that meets the YS / T 627-2013 deformed magnesium and magnesium alloy round ingot standard is heated and forged. The size of the round ingot is Φ300mm in diameter and 650mm in length. The time is 14 hours. When forging, the round ingot with a length of 650mm is first forged to 300mm, and then the circle is forged into a rectangle, and then forged with a forging ratio of 11 in the three directions of length, width, and height. The final forging temperature is 350 ℃, and finally forged into a forged plate with a thickness of 150 mm;

[0040] (2) Hot rolling: heat the forged plate obtained in step (1) at 400°C for 7 hours, and then turn to roll. First, longitudinally roll the 150mm thick forged plate into a plate with a thickness of 138mm, and then turn it into a plate with a thickness of 127mm. Then turn to longitudinal rolling to be a plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com