Neutral cleaning agent for water-in-oil cosmetics and preparation method of neutral cleaning agent

A technology for neutral cleaning agents and cosmetics, applied in the direction of chemical instruments and methods, surface active detergent compositions, detergent compositions, etc., can solve the problems of chemical corrosion of stainless steel surfaces, damage to equipment, etc., and achieve high cleaning efficiency and improved Cleaning efficiency, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

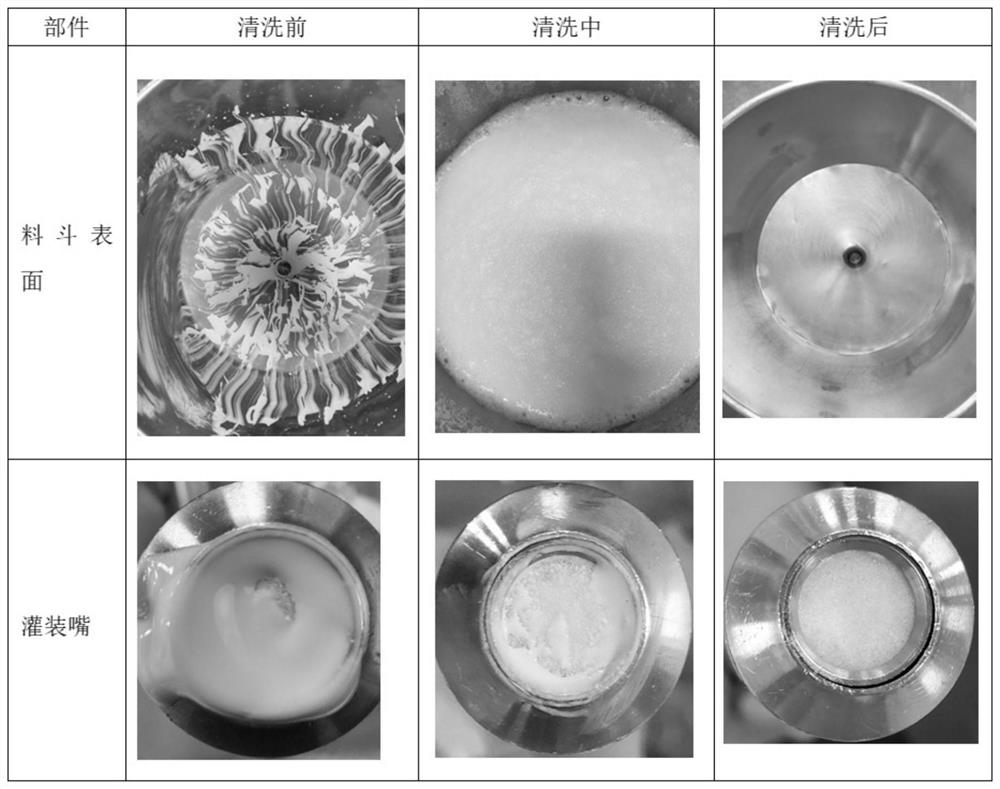

Image

Examples

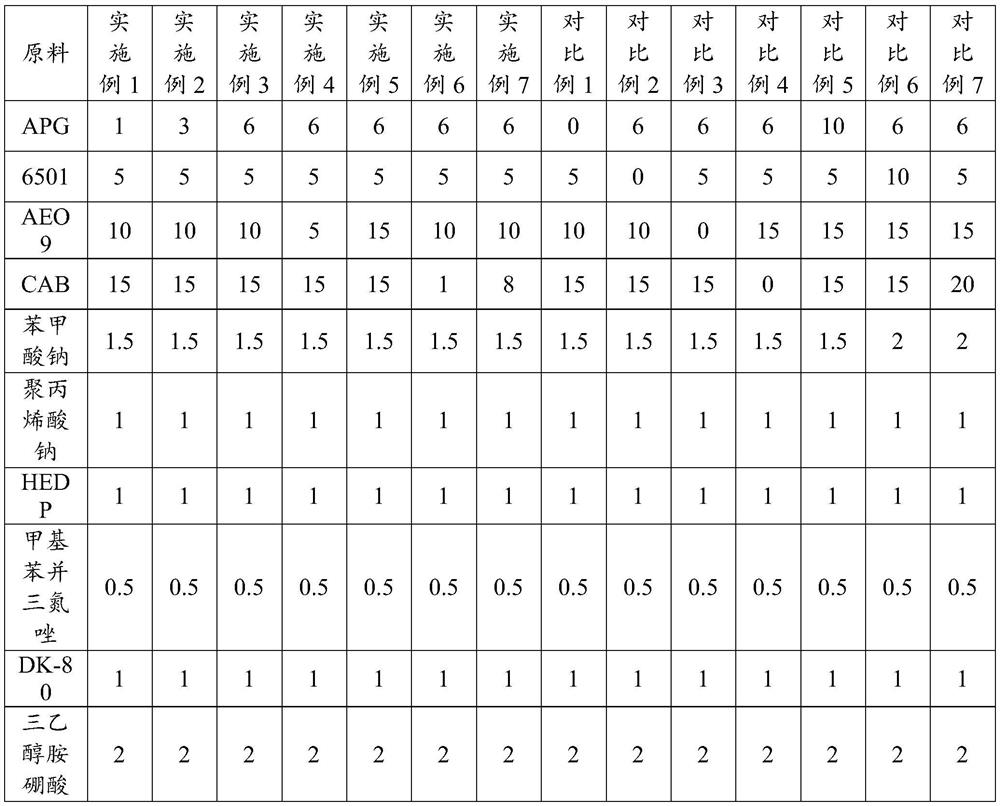

Embodiment 1~7

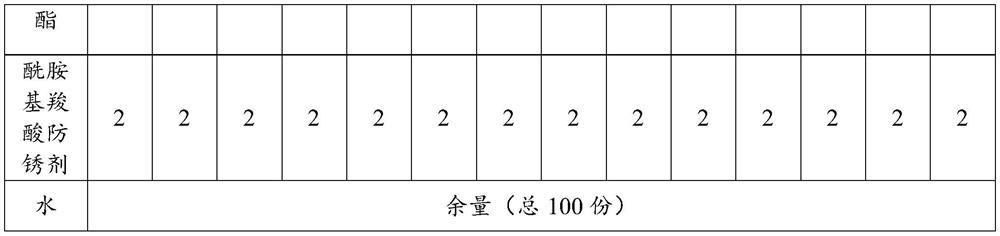

[0038] The embodiment of the neutral cleanser used for water-in-oil cosmetics of the present invention, the formula of the neutral cleanser used for water-in-oil cosmetics described in each embodiment is as shown in Table 1, wherein the non-ionic surface In the active agent, the fatty alcohol polyoxyethylene ether is AEO9, the cocoic acid diethanolamide is cocoic acid diethanolamide 6501, and the amphoteric surfactant is cocamide betaine (CAB).

[0039] The preparation method of the neutral cleaning agent for water-in-oil cosmetics described in each embodiment comprises the following steps:

[0040] (1) Put water into the reaction kettle and heat it to 30°C, then add complexing agent and keep stirring for 20 minutes until completely dissolved;

[0041] (2) Add penetrant and corrosion inhibitor into the reaction kettle, heat and stir for 30 minutes until the solution is uniform and transparent, and obtain solution B;

[0042] (3) Add a solubilizing agent, a nonionic surfactant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com