Method for performing resource utilization of sludge biocarbon

A biochar and resource-based technology, applied in the field of metallurgical sintering, can solve the problems of high environmental risks of land use and the inability of large-scale utilization of sludge biochar, so as to avoid the accumulation of heavy metal pollution, reduce solid fuel consumption, and reduce the proportion of fuel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

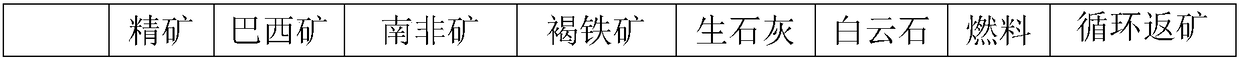

[0027] The existing sintering benchmark ingredients are shown in Table 1. Table 2 is the main chemical composition of sintered iron-containing raw materials, and the chemical composition of sludge biochar is shown in Table 3.

[0028] The composition table (mass percentage) of existing sintering reference batching of table 1

[0029]

[0030]

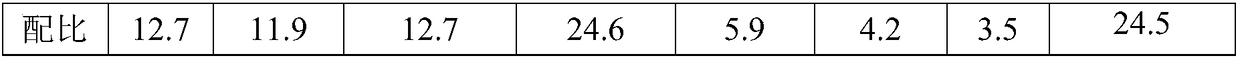

[0031] Table 2 Contents of main components of sintered iron-containing raw materials (mass percentage)

[0032]

TF

FeO

SiO 2

CaO

Al 2 o 3

MgO

Loss on Ignition (LOI)

Concentrate

65.52

27.21

5.62

0.36

1.22

0.63

0.54

brazilian mine

63.52

0.32

4.53

0.04

1.03

0.08

0.67

south african mine

65.45

0.22

3.89

0.07

0.74

0.02

0.39

57.34

0.38

6.88

0.08

2.17

0.05

9.87

Rolled Steel Scale

71.12

53.35

2.62

1.63

0.12

0.83

--

[0033] Table 3 Chemical comp...

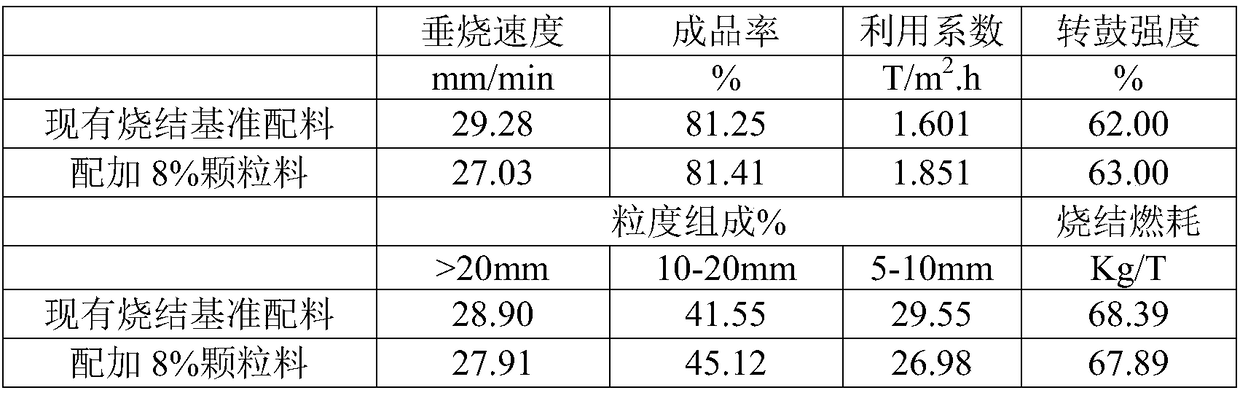

Embodiment 2

[0043] According to the scheme in the present invention, sludge biochar and rolled steel scale are mixed according to the weight percentage ratio of 80%: 20%, and disc granulation is used to prepare 0.5-3mm pellets; the pellets are mixed with a mass ratio of 5% The ratio was mixed into the existing sintered material involved in Example 1 to prepare a sintered mixture, and then sintered with a thickness of 650 mm. The sintering test results show that: compared with the sintering method without adding pellets and using a 550mm non-thick material layer, the sintering utilization coefficient increases by 6.1%, and the solid fuel consumption decreases by 1.3kg / T.

Embodiment 3

[0045] According to the scheme in the present invention, sludge biochar and rolled steel scale are mixed according to the weight percentage ratio of 70%: 30%, and disc granulation is used to prepare 0.5-3mm pellets; the pellets are mixed with a mass ratio of 3% The ratio is mixed into the mixture, and then the 700mm thick material layer is sintered for test. The results of the sintering test show that compared with the sintering method of 550mm non-thick material layer without adding pellets, the sintering utilization coefficient increases by 6.5%, and the solid fuel consumption decreases by 1.8kg / T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com