Fuel cell, and collector plate thereof

a fuel cell and collector plate technology, applied in the field of fuel cells, can solve the problems of unit cells failing to generate the desired electromotive force, reducing power generation efficiency, and relatively low electromotive force generated by those unit cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A preferred embodiment of the invention will be described hereinafter with reference to FIGS. 1 to 4.

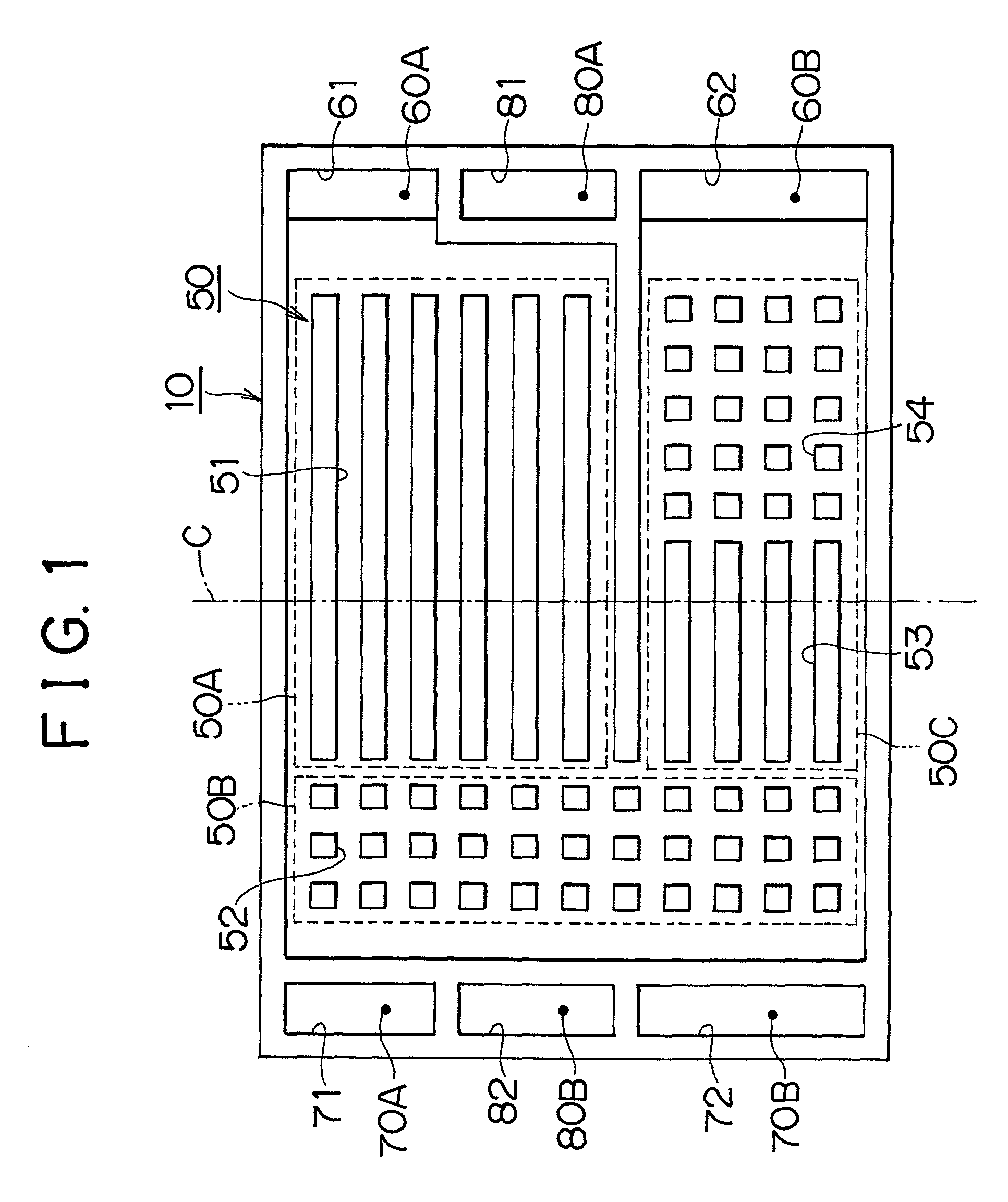

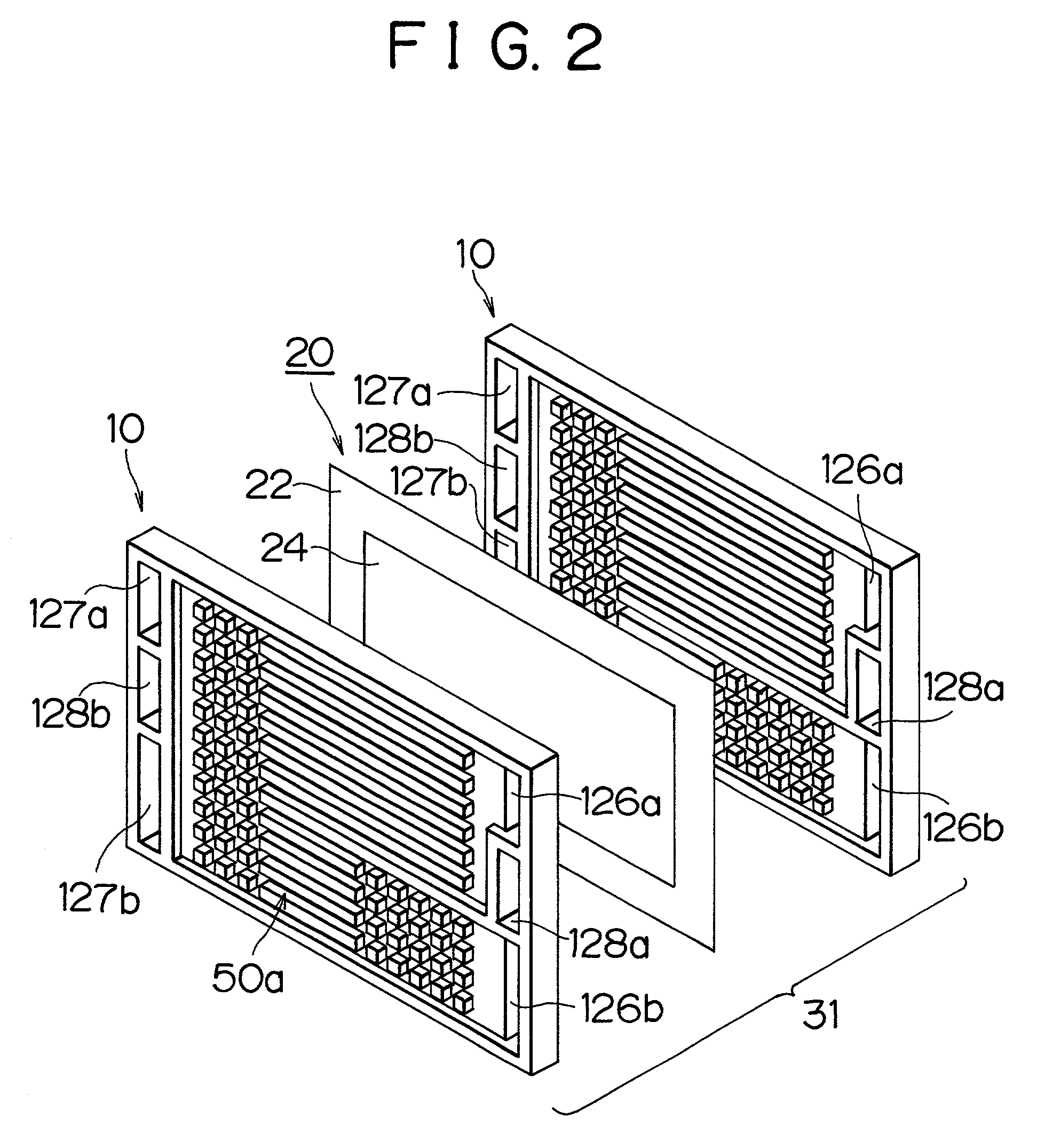

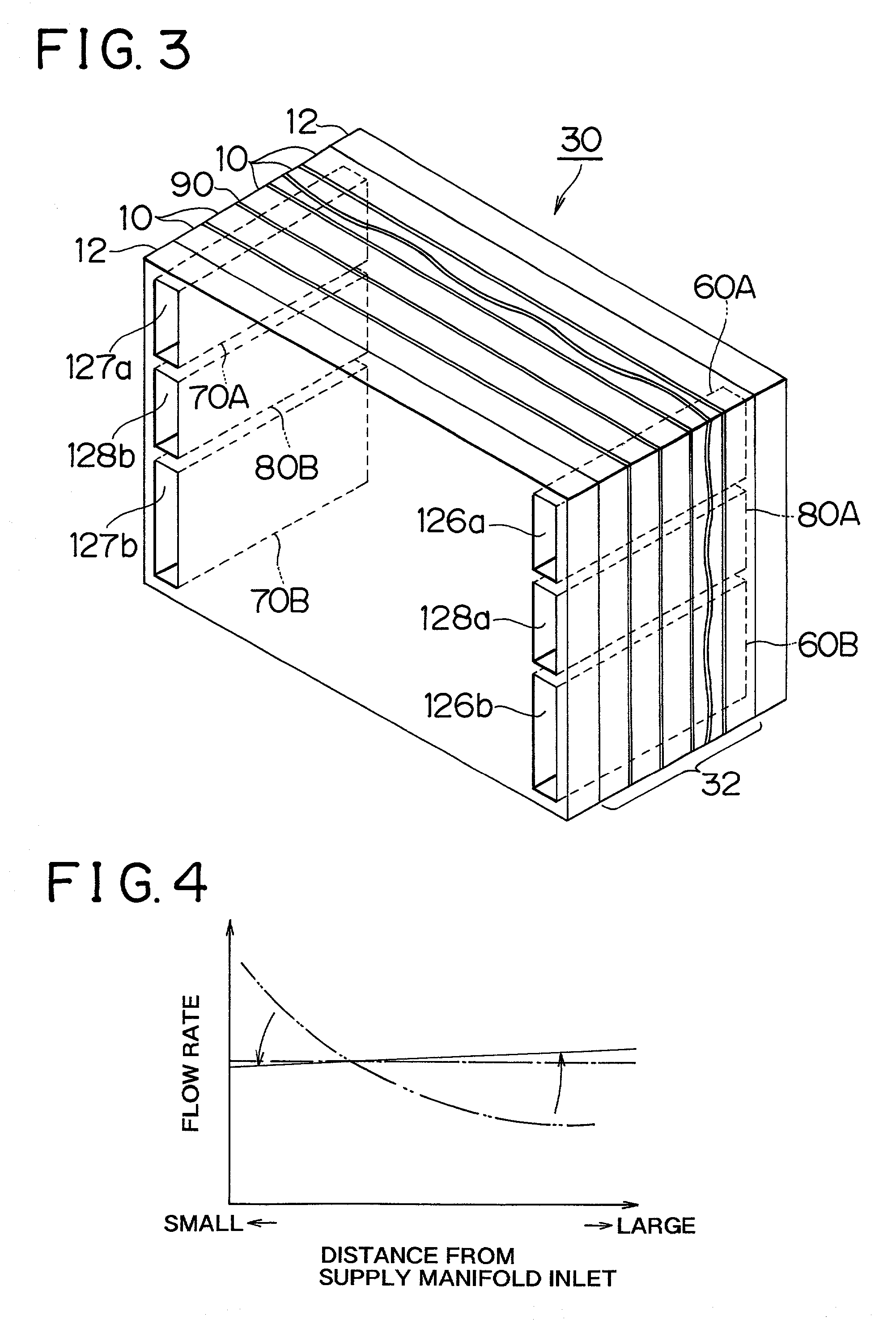

[0021] FIG. 1 illustrates a plan view construction of a collector plate 10 used in a polymer electrolyte fuel cell 30 in accordance with the embodiment. FIG. 2 illustrates an exploded view construction of a unit cell 31 of the fuel cell 30. FIG. 3 illustrates a perspective view construction of the fuel cell 30.

[0022] Referring to FIG. 3, the fuel cell 30 includes a stack 32 formed by alternately stacking a plurality of baseboards 20 and a plurality of collector plates 10, and two side plates 12 sandwiching the stack 32 on opposite sides thereof. The stack 32 is disposed so that when the fuel cell 30 is placed in a usable state, the stacking direction of the stack 32 coincides with a direction perpendicular to the direction of gravity (vertical direction in each drawing).

[0023] Each baseboard 20 has an electrolyte film 22, and reaction electrodes (a negative electrode and a pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com