Preparation method of micro-alcoholysis functional regenerated polyamide 6

A polyamide and functional technology, which is applied in the field of preparation of micro-alcoholysis functional regenerated polyamide 6, can solve the problems of limited polymerization principle, difficult application and industrialization, etc., and achieves the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

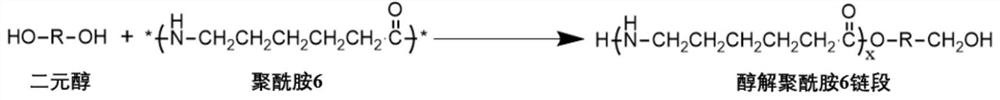

Method used

Image

Examples

Embodiment 1

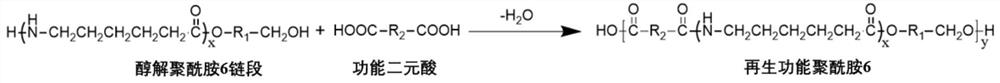

[0051] A kind of preparation method of slightly alcoholysis functional regenerated polyamide 6, concrete steps are as follows:

[0052] Raw material preparation:

[0053] Waste polyamide 6: the relative viscosity of polyamide 6 in the waste polyamide 6 is 2, the melting point is 190°C, and the number average molecular weight is 12000g / mol;

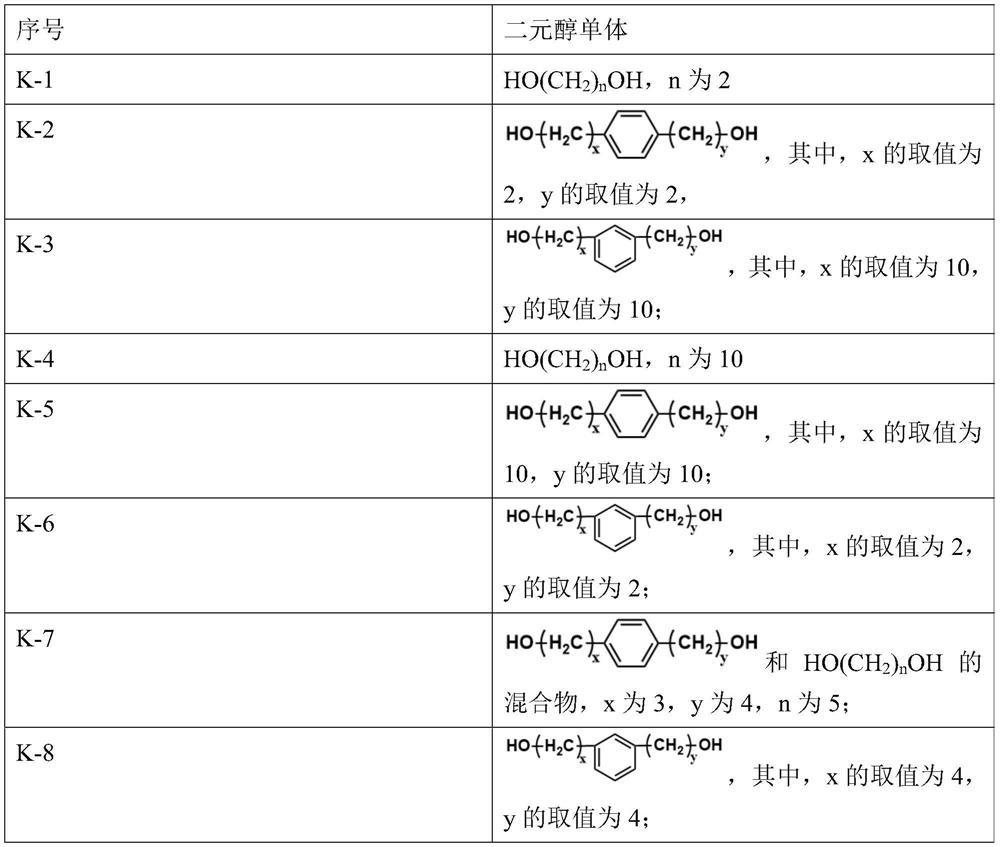

[0054] Diol monomer: K-1 in Table 1;

[0055] Functional dibasic acid monomer: [(6-oxo-6H-dibenzo[c,e][1,2]oxaphosphorin-6-yl)methyl]succinic acid;

[0056] Catalyst: tetrabutyl titanate;

[0057] Heat stabilizer: triphenyl phosphite;

[0058] Anti-ether agent: sodium acetate;

[0059] (1) Add diol monomers to waste polyamide 6, and carry out alcoholysis reaction for 2 hours at a temperature of 230°C and a pressure of 2 MPa to produce a number-average molecular weight of 7000g / mol and diols at both ends. The alcoholysis polyamide 6 segment of the esterified product structure and the amino group is used as a product; wherein, the addit...

Embodiment 2

[0063] A kind of preparation method of slightly alcoholysis functional regenerated polyamide 6, concrete steps are as follows:

[0064] Raw material preparation:

[0065] Waste polyamide 6: the relative viscosity of polyamide 6 in the waste polyamide 6 is 2.5, the melting point is 200°C, and the number average molecular weight is 14000g / mol;

[0066] Diol monomer: K-2 in Table 1;

[0067] Functional dibasic acid monomer: 2-carboxyethylphenylphosphinic acid;

[0068] Catalyst: tetrabutyl titanate;

[0069] Heat stabilizer: triphenyl phosphite;

[0070] Anti-ether agent: sodium acetate;

[0071] (1) Add diol monomers to waste polyamide 6, and carry out alcoholysis reaction for 1.6 hours at a temperature of 235°C and a pressure of 1.8 MPa, resulting in a number-average molecular weight of 7500 g / mol and two Alcoholyzed polyamide 6 chain segment with polyalcohol esterification structure and amino group as a product; wherein, the addition amount of diol monomer is 7wt% of the ...

Embodiment 3

[0075] A kind of preparation method of slightly alcoholysis functional regenerated polyamide 6, concrete steps are as follows:

[0076] Raw material preparation:

[0077] Waste polyamide 6: the relative viscosity of polyamide 6 in the waste polyamide 6 is 3, the melting point is 210°C, and the number average molecular weight is 18000g / mol;

[0078] Diol monomer: K-3 in Table 1;

[0079] Functional dibasic acid monomer: 2-carboxyethylphenylphosphinic acid;

[0080] Catalyst: titanium glycolate;

[0081] Heat stabilizer: triphenyl phosphite;

[0082] Anti-ether agent: sodium acetate;

[0083] (1) Add diol monomers to waste polyamide 6, and carry out alcoholysis reaction at a temperature of 240°C and a pressure of 1.6 MPa for 1.4 hours to produce a number-average molecular weight of 8000 g / mol and two Alcoholyzed polyamide 6 chain segment with polyalcohol esterification structure and amino group as a product; wherein, the addition amount of diol monomer is 6wt% of the waste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com