Household garbage incineration slag cleaning wastewater source pollutant treatment method

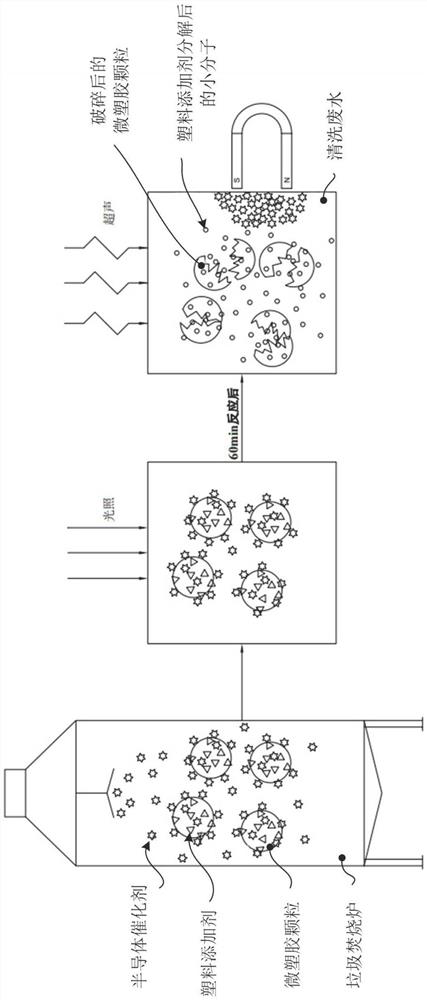

A domestic waste incineration and pollutant treatment technology, which is applied in the direction of water pollutants, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of plastic additives not being reported, so as to facilitate biological treatment and reduce plastic additives content, toxicity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention also proposes a Bi 2 WO 6 Composite lanthanum manganese and iron semiconductor photocatalyst nano material preparation method, at first 3.00g bismuth nitrate pentahydrate, 2.50g sodium tungstate dihydrate, 0.26g manganese nitrate hexahydrate, 0.30g lanthanum nitrate hexahydrate and 0.24g nine Ferric nitrate water is mixed in 60mL of ethylene glycol, and fully stirred until it is completely dissolved, then add 0.50g of oxalic acid, and continue to stir until it becomes gelatinous, then put the gelatinous mixture in an oven and dry it at 120°C to form dry gel. After the reaction is finished, the sample is ground to obtain a powdered bismuth tungstate nanomaterial with a doping amount of about 15% of lanthanum manganese and iron.

[0039] In addition, the doping amount of manganese lanthanum and iron is 10% bismuth tungstate nanomaterial, which is prepared by adjusting the quality of manganese nitrate hexahydrate and lanthanum nitr...

Embodiment 2

[0041] Adopt the Bi of above-mentioned embodiment 1 2 WO 6 The preparation method of the semiconducting photocatalyst nanometer material of composite lanthanum manganese and iron, the prepared Bi of different lanthanum manganese and iron doping amount 2 WO 6 Semiconductor photocatalyst nanomaterials compounded with lanthanum manganese and iron, and then photocatalyzed separately to degrade the matrix solution of slag cleaning wastewater containing microplastic particles. Among them, the light source power is 400W, the visible light illumination time is 120min, Bi 2 WO 6 The concentration of semiconductor photocatalyst nanomaterials composited with lanthanum, manganese and iron is 2.5g / L. The target water body to be treated is prepared by dispersing 10mg of microplastic particles in a 10mg / L slag cleaning wastewater matrix solution using a stirrer. Different lanthanum, manganese and iron The doping amount makes the data table of different samples, as follows:

[0042] ...

Embodiment 3

[0046] This embodiment utilizes Bi with lanthanum manganese and iron doping amount as 10% 2 WO 6 Cyclic experiment of photocatalytic degradation of plastic additive pollutants in microplastic particles by semiconductor photocatalyst nanomaterials composited with lanthanum manganese and iron. The light source power is 400W, Bi 2 WO 6 The concentration of semiconductor photocatalyst nanomaterials composited with lanthanum, manganese and iron is 5g / L, and the target water body is to disperse 10mg of microplastic particles in a 10mg / L slag cleaning wastewater matrix solution using a stirrer, and the light time for each photocatalytic degradation is 80min, then Bi 2 WO 6 Extraction of semiconductor photocatalyst nanomaterials composited with lanthanum manganese and iron. After 5 cycles of experiments, the bismuth tungstate material doped with 10% of lanthanum, manganese and iron is still effective in degrading the plastic additive solution in microplastic particles, only from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com