Modularized pig manure wastewater distillation recycling treatment system and method

A treatment system and modular technology, applied in the field of pig manure treatment, can solve the problems of high water content in pig manure wastewater, difficulty in wastewater discharge, and limited treatment capacity, so as to reduce the risk of epidemic infection, reduce the amount of wastewater treatment, and reduce soft water The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

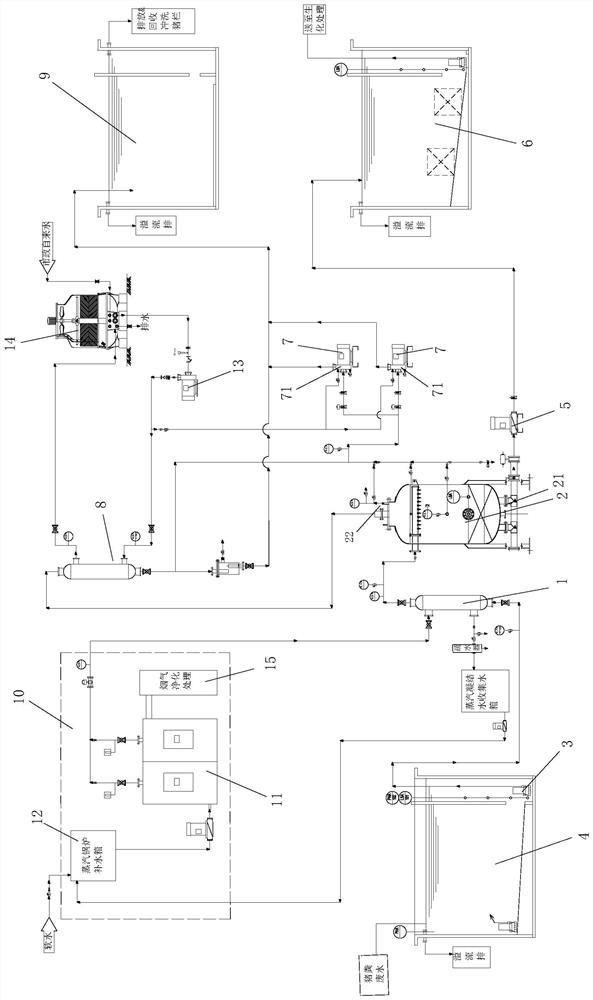

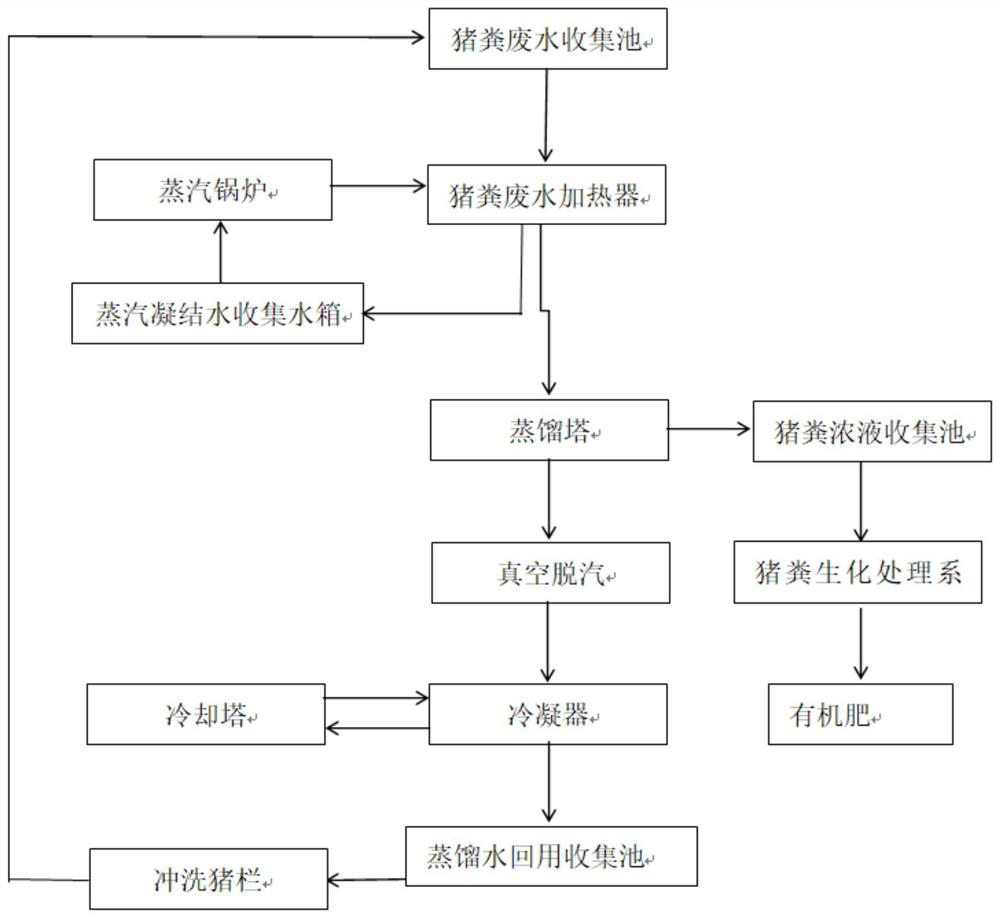

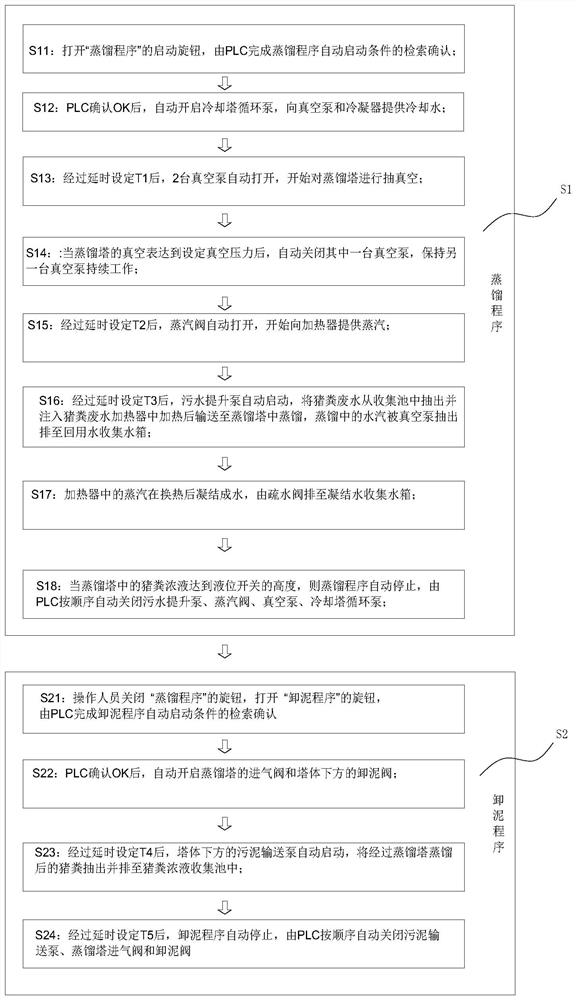

[0041] see Figure 1-2 , a modular pig manure wastewater distillation and reuse treatment system, which is divided into the following three process modules: 1) steam boiler module including equipped with flue gas purification device, water collection tank, booster water supply pump, etc.; 2) distillation tower Modules, including pig manure wastewater heaters, vacuum pumps, screw pumps, condensers, PLC control cabinets, etc.; 3) cooling tower modules, including circulating water pumps, recycling water tanks, etc.

[0042]The distillation tower module includes a pig manure wastewater heater 1 and a distillation tower 2, and the sewage lifting pump 3 extracts the pig manure wastewater from the collection tank 4 and injects it into the pig manure wastewater heater 1 to be heated and then transported to the distillation tower Distillation in 2, the bottom of the distillation tower 2 is provided with a manure discharge port 21, the manure discharge port 21 is connected with the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com