Marine-environment-resistant 5083 aluminum alloy plate strip and production method thereof

A technology for aluminum alloy plates and strips and marine environment, applied in the field of aluminum alloy manufacturing, can solve the problems of insufficient corrosion resistance of aluminum alloy plates and strips, failing to reach the level of exfoliation corrosion, long production cycle, etc., so as to avoid excessive plasticity drop. , to avoid the effect of anti-exfoliation corrosion resistance and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a production method of high-strength spalling-resistant and intergranular corrosion-resistant 5083 aluminum alloy plate and strip includes the following production process: melting and casting→sawing→milling→heating→hot rolling→cold rolling→finishing.

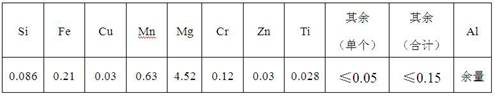

[0024] (1) Melting and casting: the mass percentage of chemical elements in the ingot after melting and casting is

[0025]

[0026] The melting temperature is 745-760°C, the refining temperature is 730-740°C, and the casting temperature is 680-690°C.

[0027] (2) Heating: Heat the ingot to 540°C and keep it warm for 2 hours.

[0028] (3) Hot rolling: the finishing temperature of the hot rough rolling is 450°C, the finishing rolling temperature of the hot finish rolling is 320°C, and the thickness of the hot rolled billet is 2.0mm.

[0029] (4) Cold rolling: After one pass of cold rolling, the hot-rolled billet is rolled to 1.85mm, and the total processing rate is 7%.

[0030] (5) Finishing: clea...

Embodiment 2

[0032] In this embodiment, a production method of high-strength spalling-resistant and intergranular corrosion-resistant cold-rolled 5083 aluminum alloy plate and strip includes the following production process: melting and casting→sawing→face milling→heating→hot rolling→cold rolling→finishing.

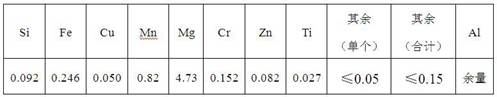

[0033] (1) Melting and casting: the mass percentage of chemical elements in the ingot after melting and casting is

[0034]

[0035] The melting temperature is 730-740°C, the refining temperature is 720-730°C, and the casting temperature is 690-700°C.

[0036] (2) Heating: heat the ingot to 520°C and keep it warm for 6 hours.

[0037](3) Hot rolling: the finishing temperature of the hot rough rolling is 420°C, the finishing rolling temperature of the hot finish rolling is 350°C, and the thickness of the hot rolled billet is 5.55mm.

[0038] (4) Cold rolling: After one pass of cold rolling, the hot-rolled billet is rolled to 5.0 mm, and the total processing rate is 9.9%.

[0039] ...

Embodiment 3

[0041] In this embodiment, a production method of high-strength spalling-resistant and intergranular corrosion-resistant cold-rolled 5083 aluminum alloy plate and strip includes the following production process: melting and casting→sawing→face milling→heating→hot rolling→cold rolling→finishing.

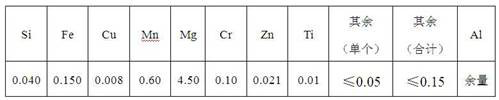

[0042] (1) Melting and casting: the mass percentage of chemical elements in the ingot after melting and casting is

[0043]

[0044] The melting temperature is 740-755°C, the refining temperature is 725-735°C, and the casting temperature is 685-695°C.

[0045] (2) Heating: heat the ingot to 500°C and keep it warm for 12 hours.

[0046] (3) Hot rolling: the finishing temperature of the hot rough rolling is 390°C, the finishing rolling temperature of the hot finish rolling is 335°C, and the thickness of the hot rolled billet is 7.95mm.

[0047] (4) Cold rolling: After one pass of cold rolling, the hot-rolled billet is rolled to 7.0 mm, and the total processing rate is 11.9%.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com