Modified resin coating and preparation method thereof

A technology for modifying resins and coatings, which is applied in the direction of conductive coatings, anti-corrosion coatings, coatings, etc. It can solve the problems of difficult construction and poor anti-corrosion performance, and achieve low surface treatment costs, good anti-corrosion performance, and simple and easy-to-operate preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The second aspect of the embodiment of the present application provides a method for preparing a modified resin coating, comprising the following steps:

[0062] S01. Provide each component according to the modified resin coating,

[0063] S02. performing the first mixing treatment on the liquid resin and the auxiliary agent to obtain the first mixture;

[0064] S03. performing a second mixing process on the first mixture, fillers and pigments to obtain a second mixture;

[0065] S04. The second mixture is mixed with polyaniline, graphene, p-toluenesulfonic acid, and glass flakes to obtain a modified resin coating.

[0066] The preparation method of the modified resin coating provided by the second aspect of the present application is simple and easy to operate, and only needs to mix the components. The preparation process is simple and easy to operate, and can be completed without large-scale equipment, which is conducive to wide application .

[0067] In step S01, ...

Embodiment 1

[0080] Modified resin paint and preparation method thereof

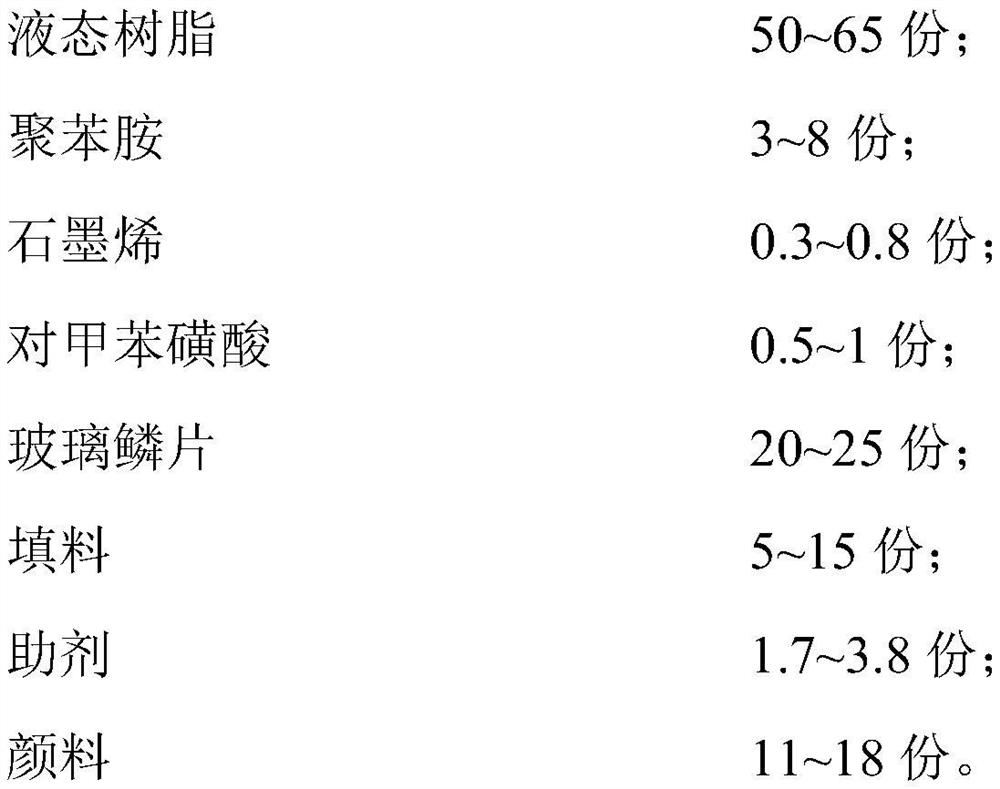

[0081] Modified resin coating

[0082] The modified resin paint comprises the following components in parts by weight:

[0083]

[0084] Among them, the liquid resin includes:

[0085] 45 parts of liquid epoxy resin;

[0086] 5 parts of liquid hydrocarbon resin;

[0087] Additives include:

[0088] 0.5 parts of dispersant;

[0089] 0.2 part of defoamer;

[0090] 1 part of anti-settling agent;

[0091] Pigments include:

[0092] 5 parts of coloring pigment;

[0093] 6 parts of anti-rust pigment;

[0094] Graphene is selected from modified graphene oxide with epoxy groups on the surface, and the particle size of graphene is 500 nanometers; the thickness of the glass flakes is 2 microns, and the diameter of the flakes is 10 microns;

[0095] The filler is selected from a mixture of talc powder and mica powder,

[0096] The dispersant is selected from supramolecular dispersants, the defoamer is selected fr...

Embodiment 2

[0105] Modified resin paint and preparation method thereof

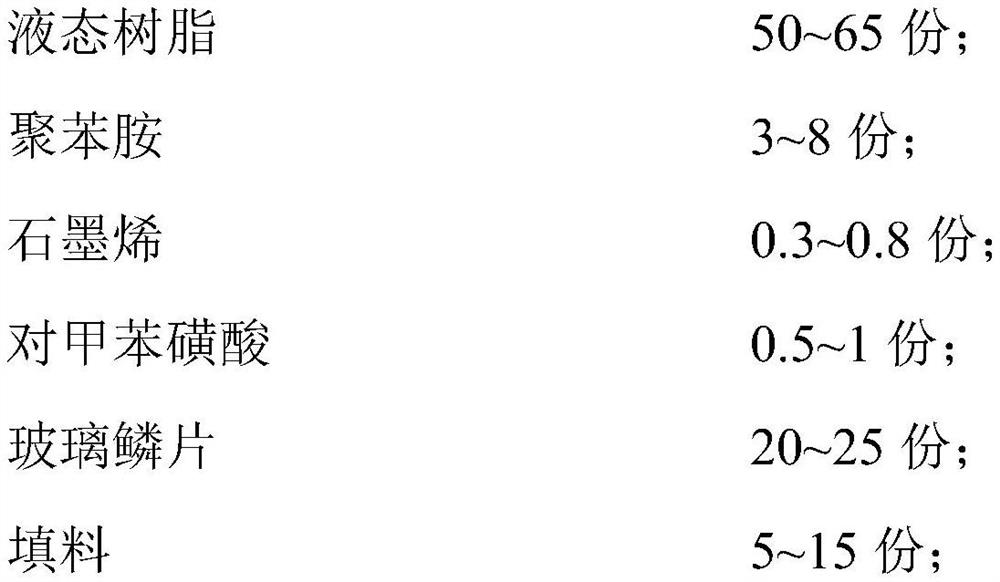

[0106] Modified resin coating

[0107] The modified resin paint comprises the following components in parts by weight:

[0108]

[0109] Among them, the liquid resin includes:

[0110] 48 parts of liquid epoxy resin;

[0111] 7 parts of liquid hydrocarbon resin;

[0112] Additives include:

[0113] 0.7 parts of dispersant;

[0114] 0.3 part of defoamer;

[0115] 1.5 parts of anti-settling agent;

[0116] Pigments include:

[0117] 7 parts of coloring pigment;

[0118] 8 parts of anti-rust pigment;

[0119] Graphene is selected from modified graphene oxide containing epoxy groups on the surface, and the particle size of graphene is 800 nanometers; the thickness of the glass flakes is 4 microns, and the diameter is 50 microns;

[0120] The filler is selected from a mixture of talc powder and mica powder,

[0121] The dispersant is selected from supramolecular dispersants, the defoamer is selected from po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com