Styrene-acrylic emulsion as well as preparation method and application thereof

A styrene-acrylic emulsion and seed technology, applied in the field of emulsion polymerization, can solve the problems of lowering softening point, easy agglomeration, large polarity difference, etc., and achieves lowering glass transition temperature, preventing agglomeration and sticking, and improving melt strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

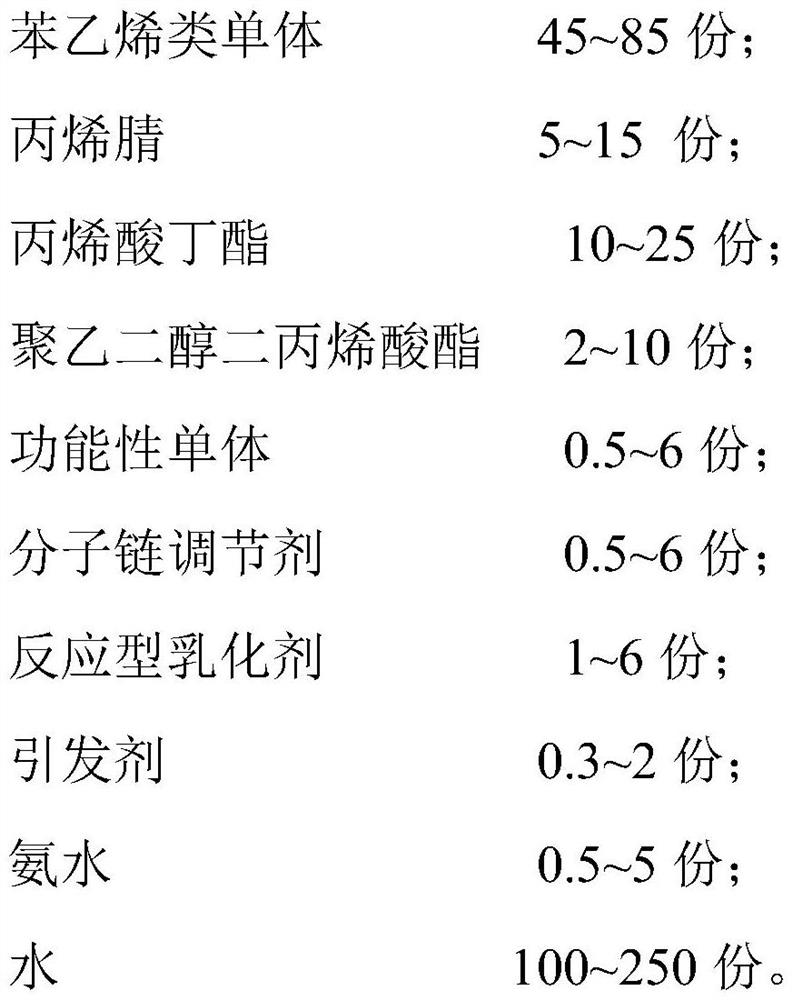

[0029] A kind of styrene-acrylic emulsion, is made up of the raw material of following parts by weight:

[0030]

[0031]

[0032] The preparation method comprises the following steps:

[0033] (1) Put 0.8 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in a beaker, add 40 parts of water to dissolve, and stir to obtain a reactive emulsifier aqueous solution; weigh 10 parts of styrene, Add 15 parts of butyl acrylate and 6 parts of polyethylene glycol diacrylate 800 into the beaker, and ultrasonically treat with the reactive emulsifier aqueous solution for 30 minutes to prepare the seed pre-emulsion;

[0034] (2) 1.2 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate is placed in a beaker, 40 parts of water are added to dissolve, and stirred to obtain a reactive emulsifier aqueous solution; 40 parts of styrene, Add 5 parts of α-methylstyrene, 5 parts of acrylonitrile, 10 parts of butyl acrylate, 4 parts of...

Embodiment 2

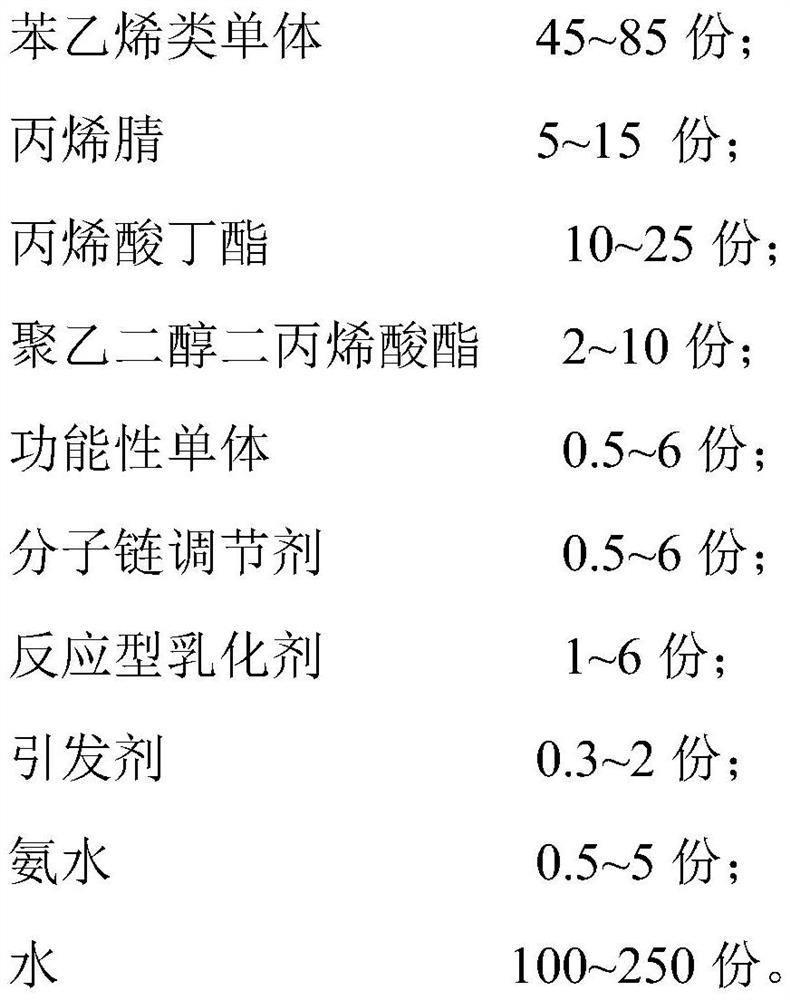

[0040] A kind of styrene-acrylic emulsion, is made up of the raw material of following parts by weight:

[0041]

[0042] The preparation method comprises the following steps:

[0043] (1) Put 1 part of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in a beaker, add 40 parts of water to dissolve, stir to obtain a reactive emulsifier aqueous solution; weigh 20 parts of styrene, Add 8 parts of butyl acrylate and 10 parts of polyethylene glycol diacrylate 200 into a beaker, and ultrasonically treat with reactive emulsifier aqueous solution for 30 minutes to prepare seed pre-emulsion;

[0044] (2) Put 2 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in a beaker, add 90 parts of water to dissolve, stir to obtain a reactive emulsifier aqueous solution; weigh 45 parts of styrene, Add 20 parts of α-methylstyrene, 15 parts of acrylonitrile, 7 parts of butyl acrylate, 2 parts of methacrylic acid, 0.5 parts of divinylbenz...

Embodiment 3

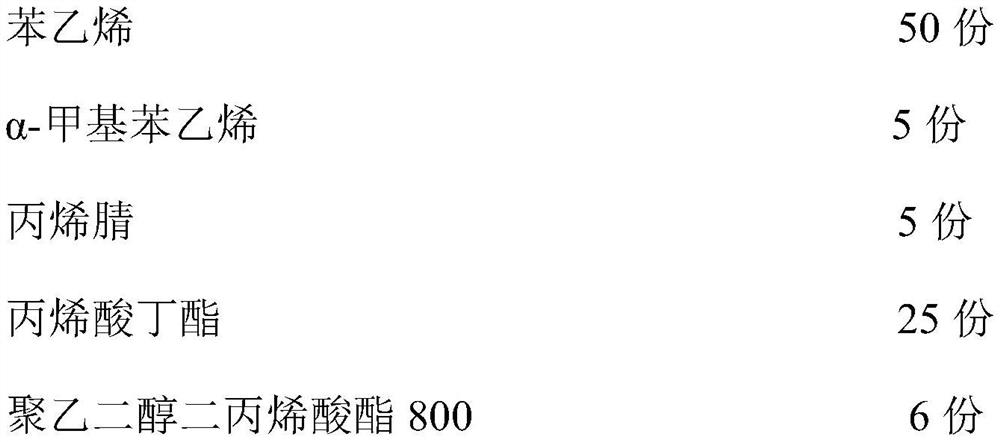

[0050] A kind of styrene-acrylic emulsion, is made up of the raw material of following parts by weight:

[0051]

[0052]

[0053] The preparation method comprises the following steps:

[0054] (1) Place 2.4 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate in a beaker, add 100 parts of water to dissolve, and stir to obtain a reactive emulsifier aqueous solution; weigh 20 parts of styrene, Add 5 parts of butyl acrylate and 10 parts of polyethylene glycol diacrylate 1200 into a beaker, and ultrasonically treat with the reactive emulsifier aqueous solution for 30 minutes to prepare the seed pre-emulsion;

[0055] (2) 3.6 parts of allyloxy nonylphenol propanol polyoxyethylene (10) ether ammonium sulfate are placed in a beaker, 120 parts of water are added to dissolve, and stirred to obtain a reactive emulsifier aqueous solution; 30 parts of styrene, 10 parts acrylonitrile, 2.5 parts alpha-methylstyrene, 15 parts butyl acrylate, 3 parts acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com