A kind of wound disinfectant and preparation method thereof

A disinfectant and wound technology, applied in the field of disinfectant, can solve the problems of poor antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In order to achieve the above object, the present invention provides the following specific embodiments and examples: a wound disinfectant, the preparation method comprising the following steps:

[0027] (1) Using cellulose and citric acid as raw materials, amidation is carried out in the catalytic system of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide reaction, wherein the mass ratio between cellulose, citric acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide was 100:280- 400:20-40:24-48, the reaction temperature is 50-80°C, and the reaction time is 3-8h. After the reaction is completed, filter, wash with deionized water, and dry to obtain citrated cellulose;

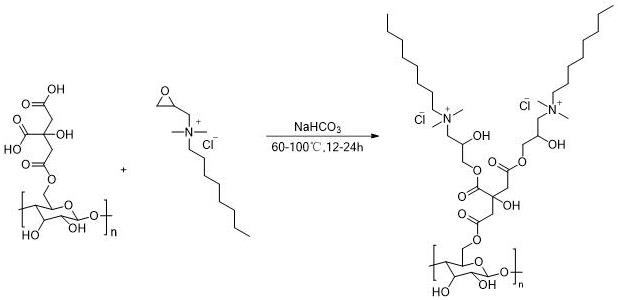

[0028] (2) Using N-dimethyl n-octylamine and epichlorohydrin as raw materials, react in ether solvent to obtain 2-epoxy dimethyl n-octyl quaternary ammonium salt;

[0029] (3) Ultrasonic disperse citrated cellulose in a mixed solven...

Embodiment 1

[0033] (1) Using cellulose and citric acid as raw materials, amidation is carried out in the catalytic system of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide Reaction wherein the mass ratio between cellulose, citric acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide is 100:280: 20:24, the reaction temperature is 50° C., and the reaction time is 3 hours. After the reaction is completed, filter, wash with deionized water, and dry to obtain citrated cellulose;

[0034] (2) Using N-dimethyl n-octylamine and epichlorohydrin as raw materials, react in ether solvent to obtain 2-epoxy dimethyl n-octyl quaternary ammonium salt;

[0035] (3) Ultrasonic disperse citrated cellulose in a mixed solvent of isopropanol and acetone, and then add sodium bicarbonate and 2-epoxy dimethyl n-octyl quaternary ammonium salt for addition esterification, in which lemon The mass ratio between acidified cellulose, sodium bic...

Embodiment 2

[0039] (1) Using cellulose and citric acid as raw materials, amidation is carried out in the catalytic system of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide Reaction wherein the mass ratio between cellulose, citric acid, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and N-hydroxysuccinimide is 100:300: 25:30, the reaction temperature is 60° C., and the reaction time is 4 hours. After the reaction is completed, filter, wash with deionized water, and dry to obtain citrated cellulose;

[0040] (2) Using N-dimethyl n-octylamine and epichlorohydrin as raw materials, react in ether solvent to obtain 2-epoxy dimethyl n-octyl quaternary ammonium salt;

[0041] (3) Ultrasonic disperse citrated cellulose in a mixed solvent of isopropanol and acetone, and then add sodium bicarbonate and 2-epoxy dimethyl n-octyl quaternary ammonium salt for addition esterification, in which lemon The mass ratio between acidified cellulose, sodium bic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com