Preparation process of additive solution of wet tissue towels and adding device used for preparation process

A production process and technology of adding equipment, applied in skin care preparations, mixers with rotating stirring devices, dissolving, etc., can solve unfavorable maintenance, cleaning and replacement, poor antibacterial performance of wet wipes additives, and purification of pure water Low-level problems, to achieve good disinfection and antibacterial effect, superior spreadability and smoothness, and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

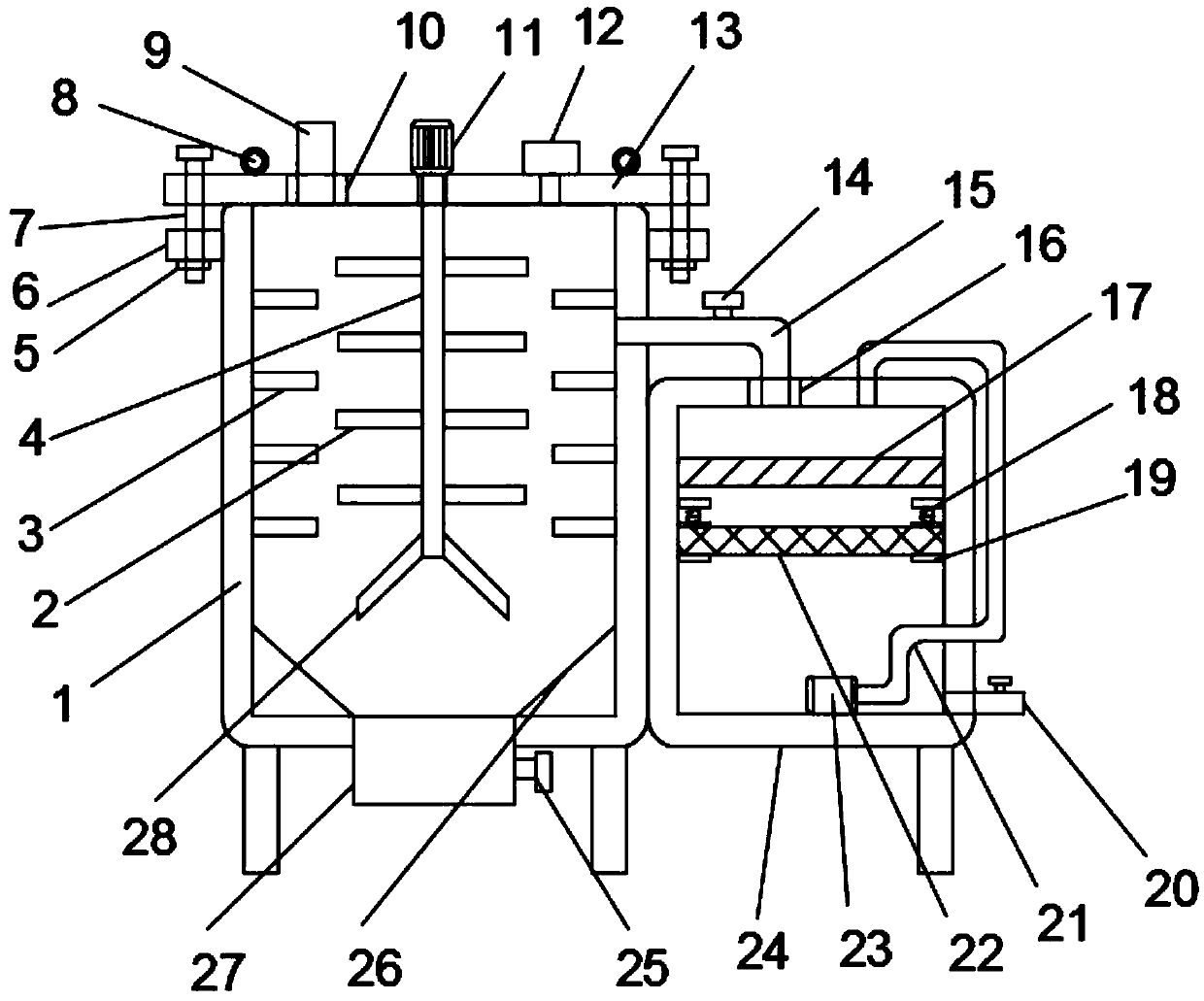

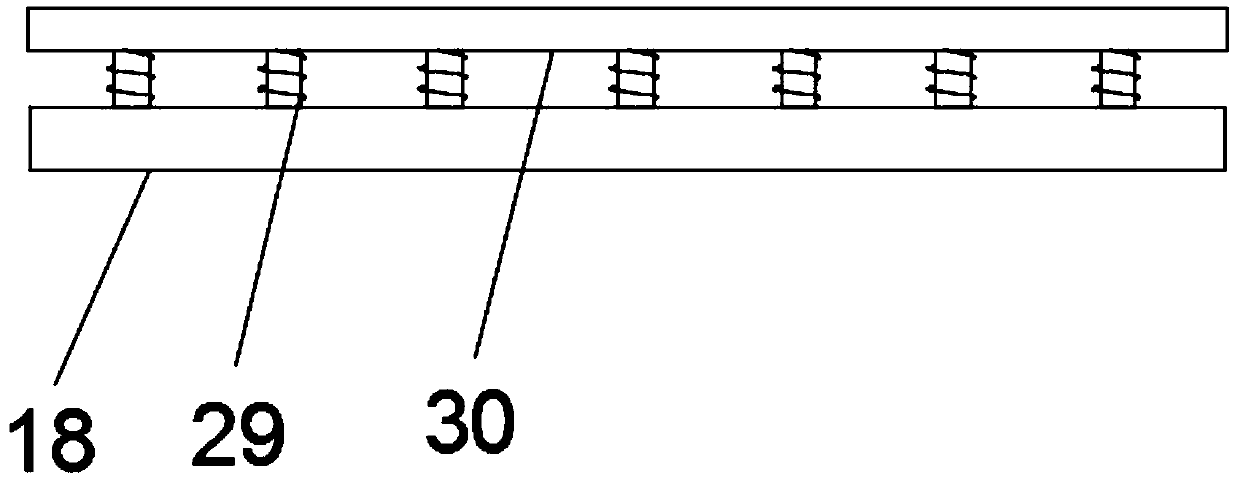

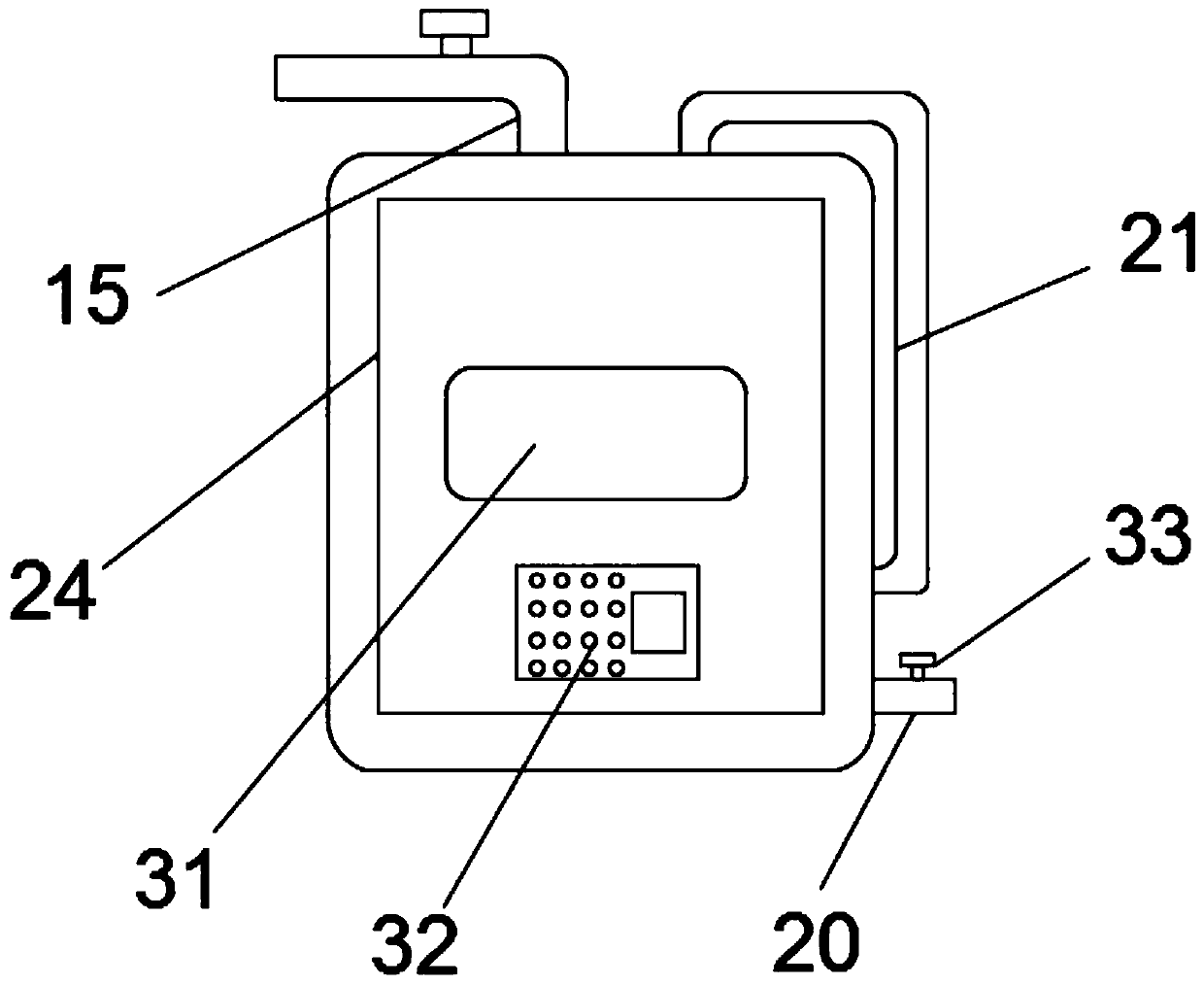

Method used

Image

Examples

Embodiment 1

[0039] A manufacturing process of a wet wipe additive liquid, the manufacturing process is prepared through the following steps:

[0040] 1) Select according to the parts by weight of raw materials: 90 parts of purified water, 20 parts of essence, 1 part of disinfectant and antibacterial agent, 1 part of emollient, 1 part of phenoxyethanol and 1 part of citric acid;

[0041] 2) First, the tap water is filtered through quartz sand and activated carbon, then its sodium ion is softened, and it is treated through reverse osmosis filtration and EDI electric desalination system, and finally it is made through ozone and ultraviolet disinfection treatment; Add purified water, then add essence, stir and mix for 35 minutes;

[0042] 3) Then add disinfectant and antibacterial agent, emollient and phenoxyethanol to the stirring reaction kettle in sequence, and stir and mix for 30-35 minutes;

[0043] 4) Finally, add citric acid into the stirred reactor, stir for 30 minutes, adjust the pH...

Embodiment 2

[0053] A manufacturing process of wet wipe additive liquid, the manufacturing process is prepared through the following steps: the same as in Example 1;

[0054] Wherein, the disinfectant and antibacterial agent is prepared from the following raw materials in parts by weight: 20 parts of hydrogen-containing silicone oil, 18 parts of glycidyl allyl ether, 22 parts of propylene alcohol polyoxyethylene polyoxypropylene allyl ether, 6 parts of tertiary ammonium hydrochloride salt and 2 parts platinum catalyst

[0055] Disinfection and antibacterial agent is prepared through the following steps:

[0056] a. Add hydrogen-containing silicone oil, glycidyl allyl ether and acryl alcohol polyoxyethylene polyoxypropylene allyl ether into a three-necked flask, add platinum catalyst solution, heat the oil bath to 140°C, and react for 5 hours to prepare epoxy poly Ether modified silicone;

[0057] b. Add tertiary ammonium hydrochloride solution into the three-necked flask, stir and heat t...

Embodiment 3

[0061] A manufacturing process of a wet wipe additive liquid, the manufacturing process is prepared through the following steps:

[0062] 1) Select according to the parts by weight of raw materials: 90 parts of purified water, 20 parts of essence, 1 part of disinfectant and antibacterial agent, 1 part of phenoxyethanol and 1 part of citric acid;

[0063] 2) First, the tap water is filtered through quartz sand and activated carbon, then its sodium ion is softened, and it is treated through reverse osmosis filtration and EDI electric desalination system, and finally it is made through ozone and ultraviolet disinfection treatment; Add purified water, then add essence, stir and mix for 30 minutes;

[0064] 3) Then add disinfectant and antibacterial agent and phenoxyethanol to the stirring reaction kettle in sequence, and stir and mix for 30 minutes;

[0065] 4) Finally, add citric acid into the stirred reactor, stir for 25 minutes, adjust the pH value of the solution in the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com