Preparation method of milk-flavor cigarette paper

A technology of cigarette paper and milk aroma, which is applied in the field of cigarette paper processing and papermaking, which can solve problems such as inconsistent sensory evaluation, loss of aroma, and impact on quality consistency of cigarettes, and achieve stable properties, improve aftertaste, and ensure sensory consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

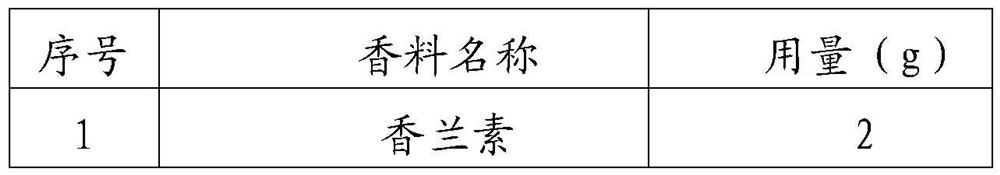

Embodiment 1

[0025] Add 5g of modified starch into 100ml of distilled water, set the stirrer speed to 500r / min, and stir for 15min to obtain a modified starch solution; then add 20g of maltodextrin while stirring at 700r / min, and continue shearing and stirring for 40min until the Evenly dispersed emulsion. Add 5g of tobacco flavor into the maltodextrin emulsion and stir, set the speed of the high-speed dispersion mixer at 7000r / min, and stir for 10min to obtain an oil-in-water (o / w) emulsion. The prepared emulsion is dried by a spray dryer to obtain the flavor microcapsule product for tobacco, and the microcapsules are formulated into a milk-flavored essence according to the ratio in Table 1, and then coated on the cigarette paper according to 0.5% of the weight of the cigarette paper. After being dried at a high temperature, a milk-flavored cigarette paper is obtained. Cigarette products are made by conventional techniques in the field, and then sensory evaluation is carried out accordin...

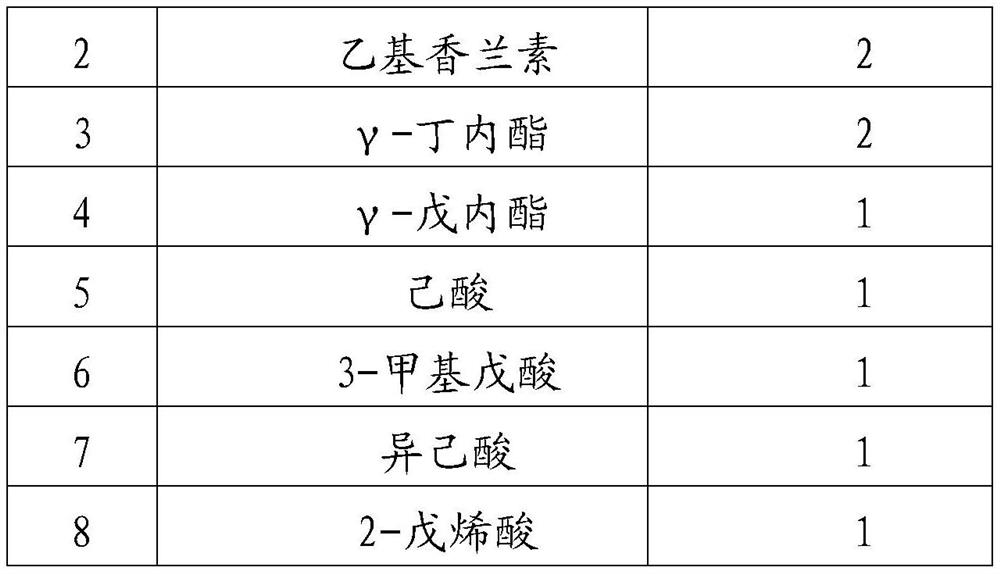

Embodiment 2

[0031] Add 10g of modified starch into 100ml of distilled water, set the stirrer speed at 500r / min, and stir for 20 minutes to obtain a modified starch solution; then add 30g of maltodextrin while stirring at 700r / min, and continue to shear and stir for 40min until it forms Evenly dispersed emulsion. Add 10 g of tobacco flavor into the maltodextrin emulsion and stir, set the speed of the high-speed dispersion mixer at 7000 r / min, and stir for 10 minutes to obtain an oil-in-water (o / w) emulsion. The prepared emulsion is dried by a spray dryer to obtain the flavor microcapsule product for tobacco, and the microcapsules are formulated into a milk-flavored essence according to the ratio in Table 2, and then coated on the cigarette paper according to 1% of the weight of the cigarette paper. After being dried at a high temperature, a milk-flavored cigarette paper is obtained. Cigarette products are made by conventional techniques in the field, and then sensory evaluation is carried...

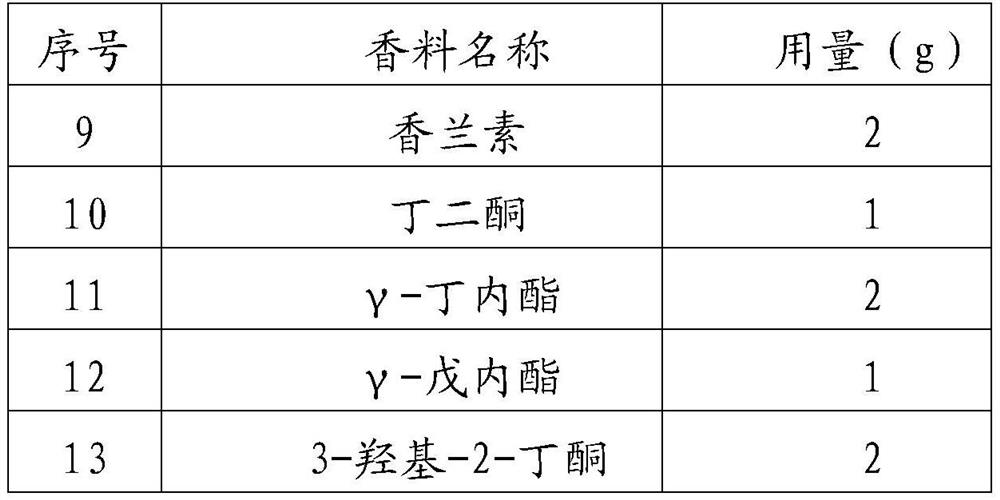

Embodiment 3

[0037] Add 15g of modified starch into 100ml of distilled water, set the stirrer speed at 500r / min, and stir for 25min to obtain a modified starch solution; then add 30g of maltodextrin while stirring at 700r / min, continue shearing and stirring for 45min until the Evenly dispersed emulsion. Add 15g of tobacco spices into the maltodextrin emulsion for stirring, set the speed of the high-speed dispersion mixer at 7000r / min, and stir for 15 minutes to obtain an oil-in-water (o / w) emulsion. The prepared emulsion is dried by a spray dryer to obtain the flavor microcapsule product for tobacco, and the microcapsules are formulated into a milk-flavored essence according to the ratio in Table 3, and then coated on the cigarette paper according to 2% of the weight of the cigarette paper. After being dried at a high temperature, a milk-flavored cigarette paper is obtained. Cigarette products are made by conventional techniques in the field, and then sensory evaluation is carried out acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com