Solid waste, sintering and pelletizing co-treatment process capable of guaranteeing iron grade

A technology of co-processing and iron grade, which is applied in the field of co-processing of pellets, sintering, solid waste, and solid waste treatment technology, can solve the problem that the product quality, function and status of the sintering process and pelletizing process are not fully exerted, Can not adapt to the solid waste output of iron and steel plants, etc., to achieve the effect of improving the efficiency and effect of incineration and/or pyrolysis, uniform temperature distribution of the kiln body, and improving the effect of reduction treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

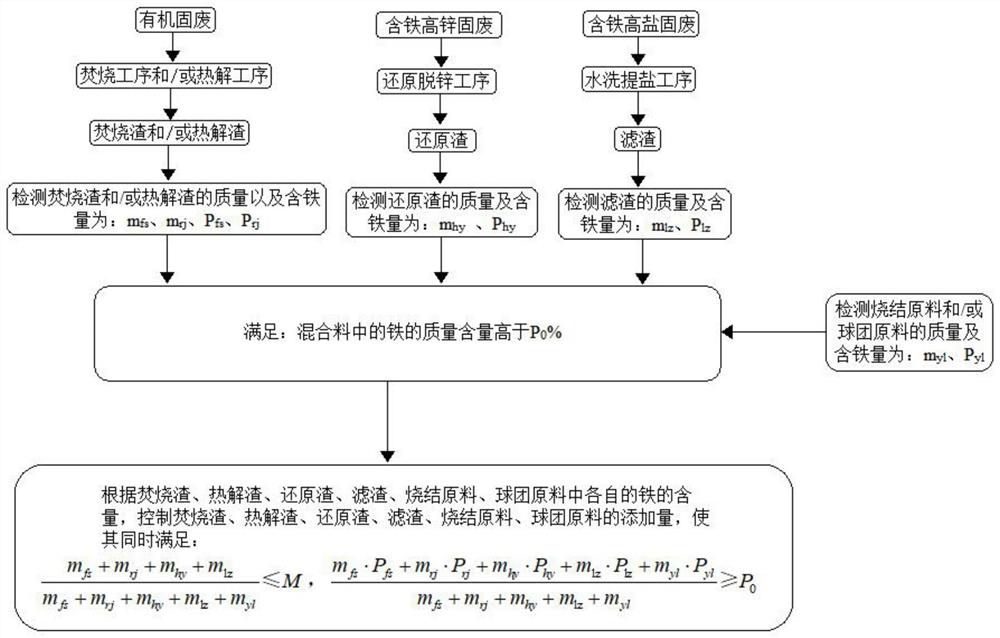

[0148] Such as figure 1 As shown, a co-processing process of solid waste, sintering, and pellets to ensure iron grade, the process includes the following steps:

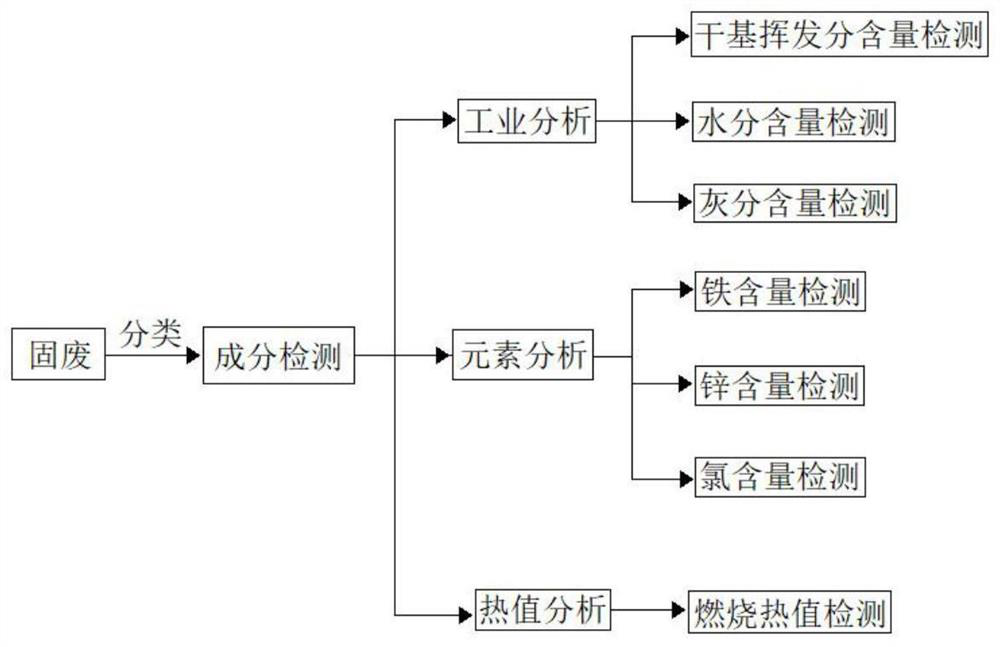

[0149] (1) Solid waste: Classify the solid waste of iron and steel enterprises and urban municipal solid waste into organic solid waste, solid waste containing iron and high zinc, and solid waste containing iron and high salt.

[0150] (2) Solid waste pretreatment:

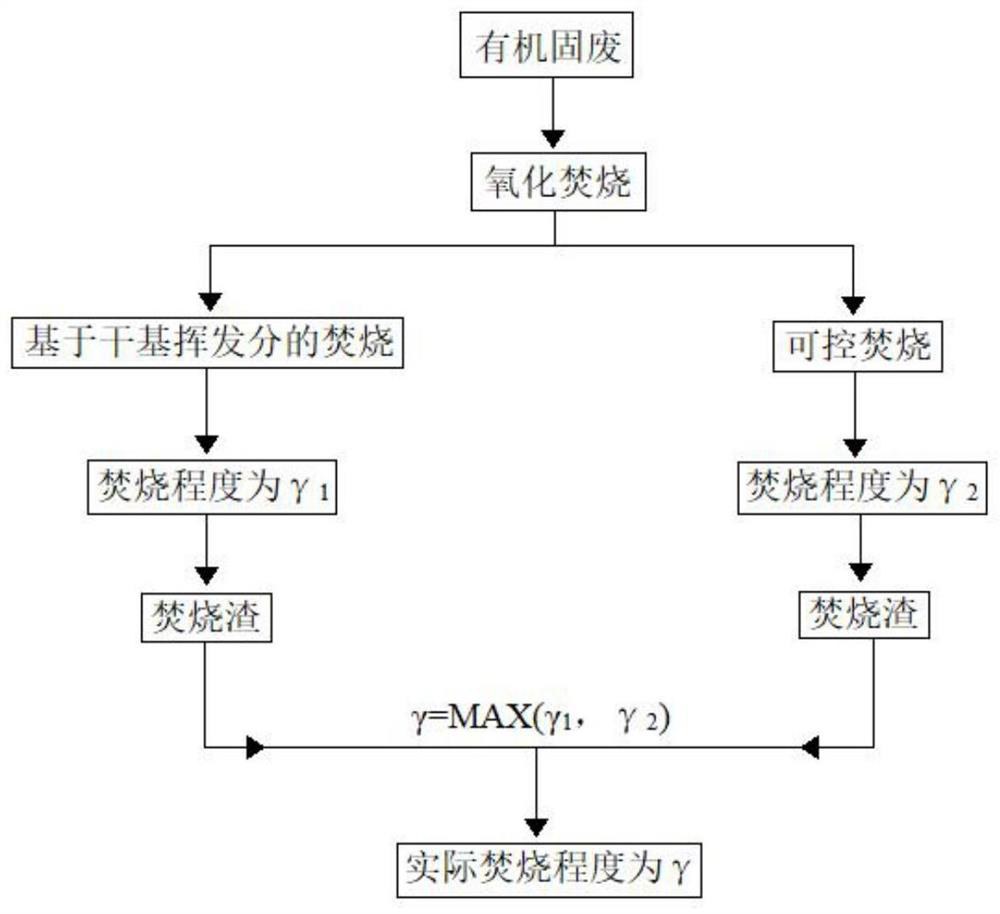

[0151] a) performing an incineration process on the organic solid waste to obtain incineration slag and performing a pyrolysis process on the organic solid waste to obtain pyrolysis slag.

[0152] b) The iron-containing high-zinc solid waste is subjected to a reduction dezincification process to obtain reduction slag and zinc-containing by-products.

[0153] c) The iron-containing high-salt solid waste is subjected to a water-eluting salt process to obtain brine and filter residue.

[0154] (3) Co-processing: Mix the incineration slag, pyrolysis slag...

Embodiment 2

[0157] Repeat Example 1, but mix the incineration slag, pyrolysis slag, reduction slag, and filter residue obtained in step (2) together with the pellet raw material, and then transport the mixed mixture to the pelletizing process. P 0 is 50 and M is 4.5.

Embodiment 3

[0159] Repeat Example 2, but control the incineration residue, pyrolysis residue, reduction residue, filter residue, sintering raw material, pelletizing The amount of raw materials added, so as to control the mass content P% of iron in the mixed mixture to meet P 0 % range required. Specifically:

[0160] where: m fs is the material mass of incineration slag, m rj is the material mass of pyrolysis slag, m hy is the mass of reducing slag, m lz is the material mass of filter residue, m yl is the material quality of sintered raw materials and pellet raw materials, P fs is the iron content in the incineration slag, P rj is the iron content in pyrolysis slag, P hy is the iron content in the reduction slag, P lz is the iron content in the filter residue, P yl is the content of iron in sintering raw materials and pellet raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com