Method for simultaneously reducing accumulation of citrulline and ethyl carbamate in fermented food

A technology of urethane and fermented food, applied in the preparation of vinegar, food science, preparation of alcoholic beverages, etc., to achieve the effects of stable effect, simple operation and obvious application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Direct fermentation without adding additives in the fermentation process

[0027] Mix the koji and brine at a ratio of 1:2 (m / v), that is, 1.5kg of koji, and the final concentration of the brine is 18%. After stirring evenly, transfer it to a 5L fermenter for fermentation, and place the fermenter in a constant temperature incubator at 15°C Medium fermentation for one month, stirring once a week; then placed in a 30-35°C environment for natural fermentation.

[0028] At regular intervals, use sterile gloves and a straw to take about 50 g of moromi and filter it with gauze. After standing overnight at 4° C., take the supernatant for measurement. Use the same method to filter all the remaining moromi for raw soy sauce, and take the supernatant after standing overnight at 4°C for measurement. When sterilizing, add ethanol to the raw soy sauce to make the concentration reach 2%, sterilize at 85°C for 30 minutes, put it in an ice bath and lower it to 4°C quickl...

Embodiment 2

[0029] Example 2: Fermentation after adding rutin to moromi

[0030] With reference to the fermentation process in Example 1, 60 mg / kg rutin was added to the moromi based on the mass of moromi mixed with koji and brine, and then transferred to a 5L fermenter for fermentation. Other implementation conditions were the same as in Example 1.

Embodiment 3

[0031] Example 3: Fermentation after adding quercetin and gallic acid to the moromi

[0032] Referring to the fermentation process in Example 1, based on the mass of moromi mixed with koji and brine, add quercetin and gallic acid respectively to the moromi so that the concentrations are 100mg / kg and 10mg / kg, and then transfer to 5L Fermentation in the fermenter, other implementation conditions are with embodiment 1.

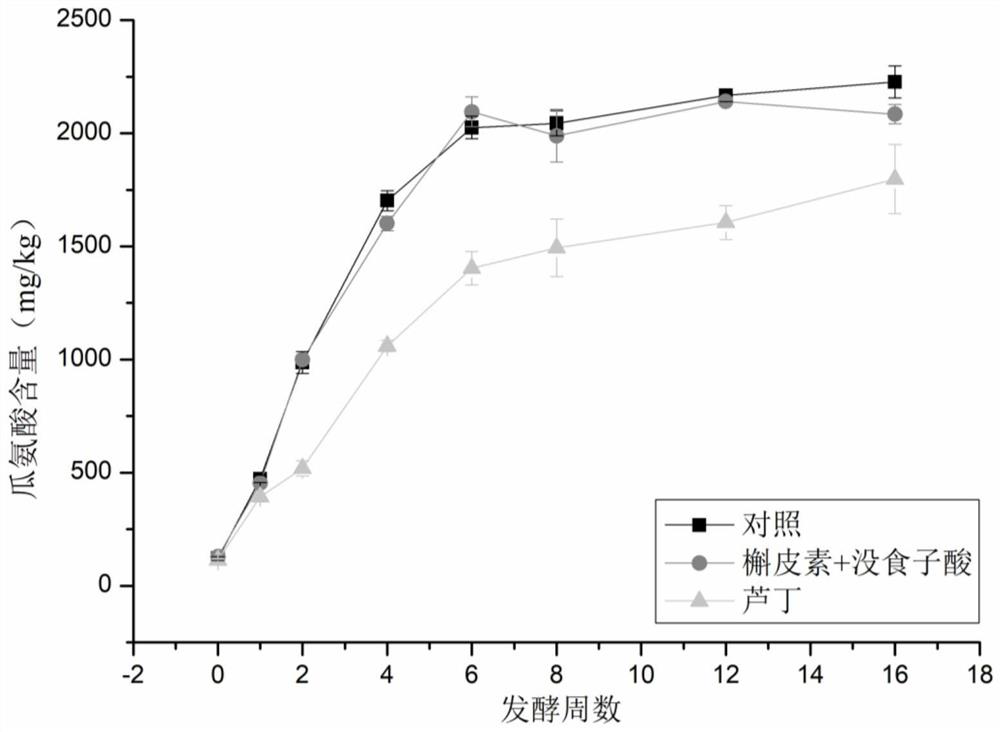

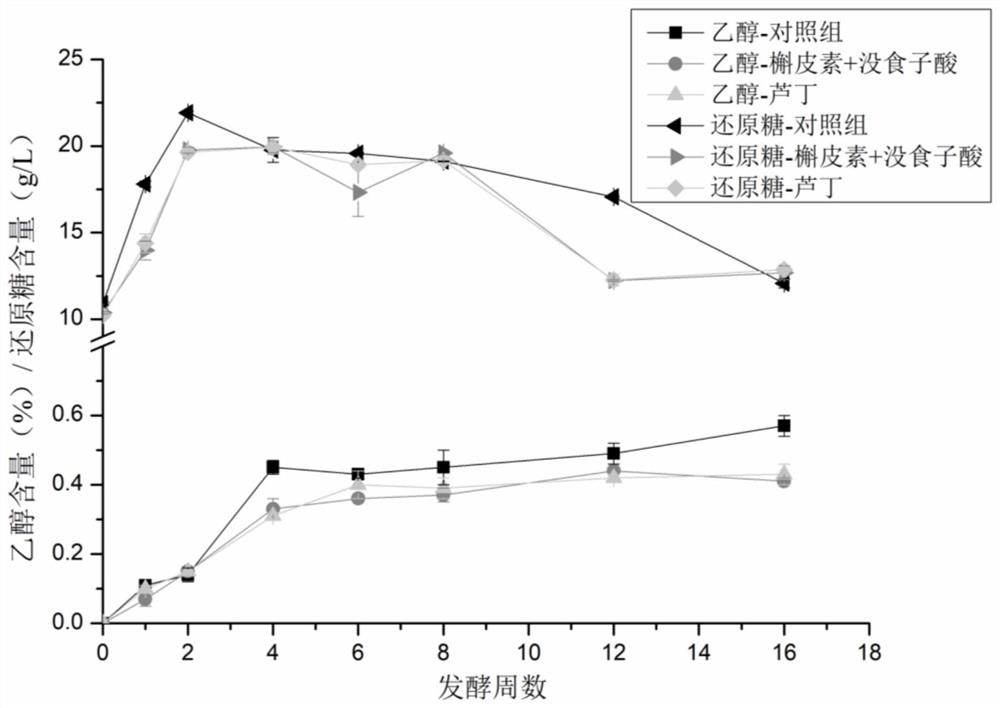

[0033] Determination of the content of ethyl carbamate, citrulline, ethanol, reducing sugar and volatile components in the samples taken, the results are shown in the attached figure 1 - attached Figure 4 .

[0034] From attached figure 1 It can be seen that the addition of polyphenols in the examples can delay the generation time of ethyl carbamate, and reduce the content of ethyl carbamate in the final fermentation broth, which is reduced by 64.7% and 51.1% in Example 2 and Example 3 respectively , with figure 2 It showed that the addition of rutin had a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com