Carbon-based amphiphilic nanoflow for oil displacement and preparation method

A carbon-based nano, carbon-based technology, applied in the direction of nano-carbon, chemical instruments and methods, carbon compounds, etc., to achieve the effect of improving oil displacement efficiency, improving oil recovery, and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

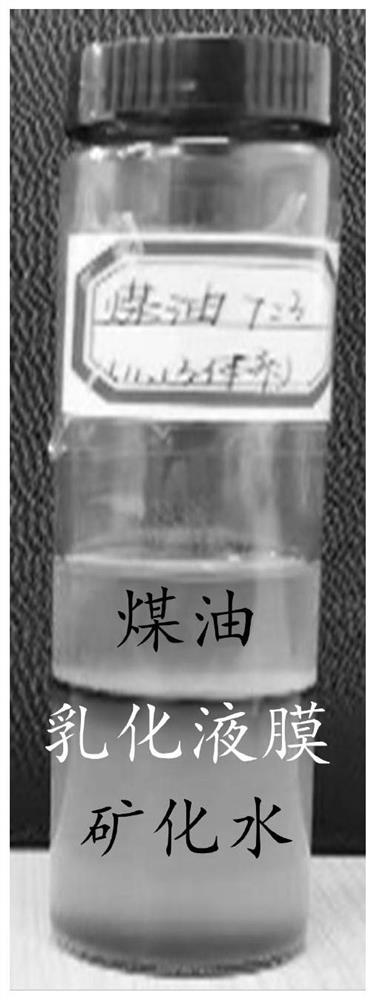

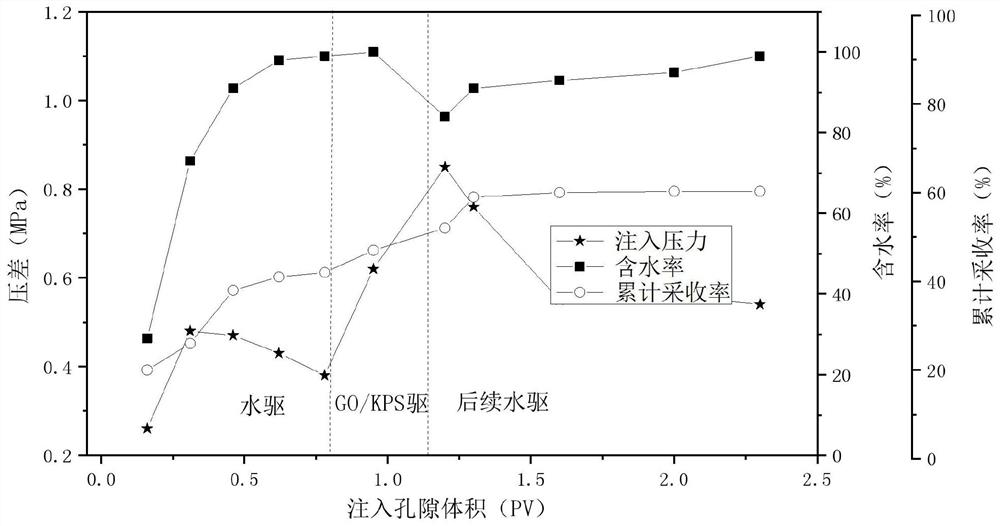

Image

Examples

Embodiment 1

[0032] Add 10g of graphite powder to a 500mL three-necked bottle, then add 80g of toluene and dimethylformamide solvent (mass ratio 1:1), stir in an oil bath at 80°C for 60min; The agent N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane is added to the graphite powder solution, sealed and stirred, and reacted in an oil bath at 96°C for 6 hours, filtered, purified, and dried to obtain Coupling agent modified graphite powder. Add 3g of coupling agent-modified graphite powder into a 500mL three-necked bottle, then add 15g of toluene and dimethylformamide solvent (mass ratio 1:1), stir in an oil bath at 80°C for 60min; in an oil bath at 90°C Add 1.5g of polyoxyethylene ether into the graphite powder solution modified by the coupling agent under certain conditions, seal and stir, react in an oil bath at 90°C for 6h, filter with suction, purify, and dry to obtain carbon-based amphiphilic nanofluid 1.

Embodiment 2

[0034] Add 13g of carbon powder to a 500mL three-necked bottle, then add 90g of toluene and dimethylformamide solvent (mass ratio 1:1), stir in an oil bath at 80°C for 60min; The agent γ-aminopropyltriethoxysilane was added to the carbon powder solution, sealed and stirred, and reacted in an oil bath at 96° C. for 6 hours, filtered, purified, and dried to obtain the carbon powder modified by the coupling agent. Add 6g of carbon powder modified by coupling agent into a 500mL three-necked bottle, then add 20g of toluene and dimethylformamide solvent (mass ratio 1:1), stir in an oil bath at 80°C for 60min; in an oil bath at 90°C Add 2.0 g of polyoxyethylene ether to the solution of the coupling agent modified carbon powder under the conditions; seal and stir, react in an oil bath at 90° C. for 6 hours, filter with suction, purify, and dry to obtain the carbon-based amphiphilic nanofluid 2 .

Embodiment 3

[0036] Add 12g of graphene to a 500mL three-necked bottle, then add 100g of toluene and dimethylformamide solvent (mass ratio 1:1), stir in an oil bath at 80°C for 60min; Agent N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, 5g of coupling agent γ-aminopropyltriethoxysilane are added to the graphene dispersed, sealed and stirred, in an oil bath at 96 ℃ for 6h, suction filtration, purification, and drying to obtain coupling agent-modified graphene; add 3.2g coupling agent-modified graphene to a 500mL three-necked bottle, then add 30g toluene and dimethylformamide Solvent (mass ratio 1:1), in an oil bath at 80°C, stir for 60min; under the condition of an oil bath at 90°C, add 3.3g of polyoxyethylene ether to the graphene solution modified by the coupling agent, seal and stir, in the oil bath The reaction was carried out at 90° C. for 6 hours, and the carbon-based amphiphilic nanofluid 3 was obtained by suction filtration, purification and drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com