Carbon black as well as preparation method and application thereof

A carbon black and oxidized carbon black technology, applied in electrical components, magnetic field/electric field shielding, fibrous fillers, etc., can solve problems such as difficulty in producing high-quality carbon black products, achieve high oil absorption value, improve porosity, and improve electrical conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

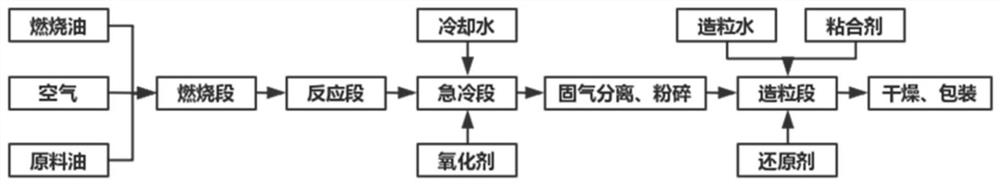

[0047]In this example, a carbon black is prepared, and the processing flow is schematically figure 1 As shown, the specific process is:

[0048] S1: The combustion segment to the reactor is 60: 1 to add coal tar and air, coal tar and air in combustion segments in combustion segments;

[0049] S2: Add the raw oil to the reaction group of the reactor, and the reaction temperature is 1850 ° C to 1900 ° C, the pressure is 0.5 MPa, and the raw oil is cleaved, and when the aggregate is formed, the cooling water is sprayed at a speed of 5 kg / h. Cooling carbon black smoke, terminating carbon black reaction, while adding mass concentrations in cooling water to 1 kg / m 3 Potassium permanganate, catalyzes carbon black aggregate, and obtain carbon black flue gas in developed pore structure;

[0050] S3: Set the pressure of the wind to the wind to the wind to 700 MPa, and the carbon black flue gas produced by S2 is further cooled in the heat exchange device to about 260 ° C, and the carbon ...

Embodiment 2

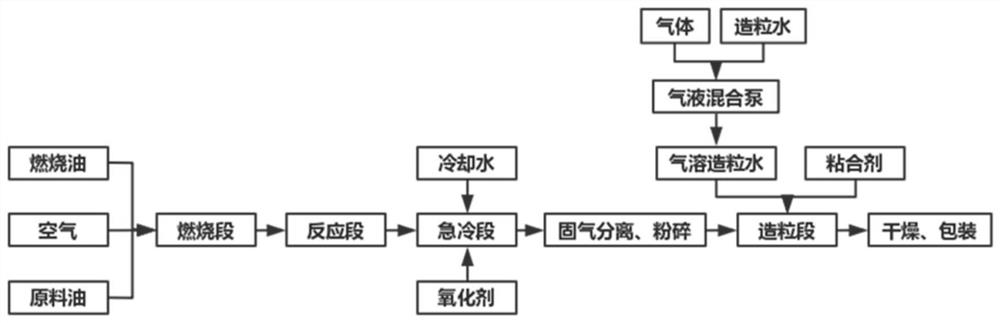

[0054] In this example, a carbon black is prepared, and the processing flow is schematically figure 2 As shown, the specific process is:

[0055] S1: The combustion segment to the reactor is 65: 1 to the mass flow ratio of 65: 1 to the coal tar and air, coal tar and air in the combustion section;

[0056] S2: Add a raw oil to the reaction furnace reaction to the reaction furnace, and the reaction temperature is 1850 ° C to 1900 ° C, the pressure is 0.6 MPa, and the raw oil has a cleavage reaction and gradually forms a gas at a rate of 7 kg / h, and sprayed cooling water. Cooling carbon black smoke, terminating carbon black reaction, while adding mass concentrations in cooling water to 1.2kg / m 3 Dilute nitric acid, catalytically activate carbon black aggregate, and obtain carbon black flue gas in developed pore structure;

[0057] S3: Set the pressure of the wind feed pipe in the wind to 800 MPa, and the carbon black flue gas produced by S2 is further cooled in the heat exchange ...

Embodiment 3

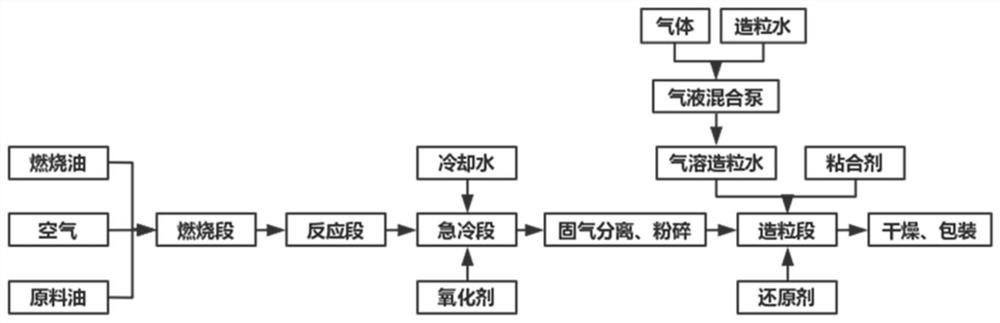

[0061] In this example, a carbon black is prepared, and the processing flow is schematically image 3 As shown, the specific process is:

[0062] S1: The combustion segment to the reactor is 70: 1 to the mass flow ratio of 120 ° C, the coal tar and air, coal tar and air combust in the combustion section;

[0063] S2: Add the raw oil to the reaction furnace to the reaction furnace, and the reaction temperature is 1850 ° C to 1900 ° C, the pressure is 0.5 MPa, the raw oil is cleaved, and when the aggregate is formed, the cooling water is sprayed at a speed of 9 kg / h. , Cooling carbon black smoke, terminating carbon black reaction, while adding mass concentrations in cooling water to 1.5 kg / m 3 Iodine, catalytically activate carbon black aggregate, and obtain carbon black flue gas in developed pore structure;

[0064] S3: Set the pressure of the wind feed pipe in the wind to 900MPa, and the carbon black flue gas produced by S2 is further cooled to about 240 ° C in heat exchange eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com