Polyvinylidene fluoride hollow fiber microfiltration membrane and preparation method thereof

A technology of polyvinylidene fluoride and polychlorotrifluoroethylene, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of discoloration of polyvinylidene fluoride matrix, affect the service life of the membrane, and reduce the service life of the membrane and other problems, to reduce the difficulty of recycling, change the crystallization behavior, and reduce the effects of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

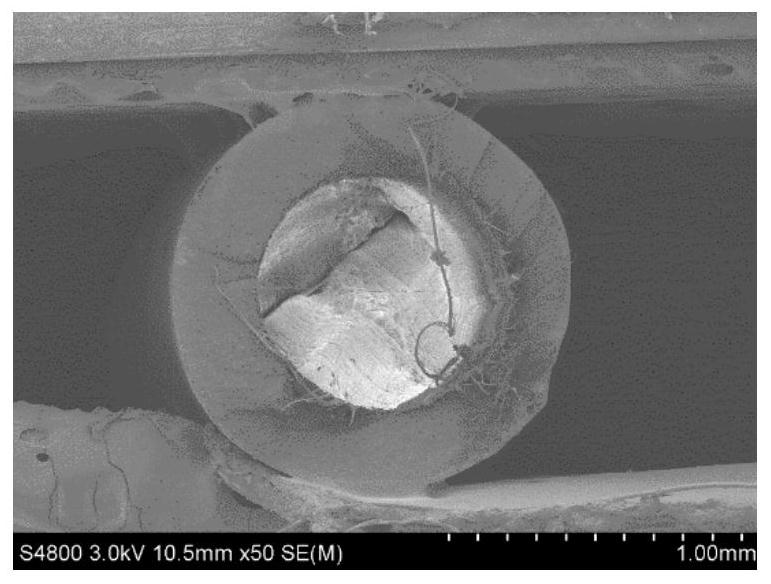

[0040] Accurately weigh 27 parts of polymer PVDF, 4 parts of polychlorotrifluoroethylene, 33 parts of the first diluent benzophenone (DBK) and 36 parts of the second diluent dimethyl phthalate (DMP). Among them, DBK is ground by a ball mill and then sieved. The above raw materials are mixed evenly by a kneader, and fed into a twin-screw extruder by screw forced side feeding. It is heated and melted completely in the discharge machine and extruded from the nozzle of the die head. The temperature of the die head is set at 175°C. The inner cavity of the hollow film die head is supported by air, and the air pressure is 3kPa. The extruded membrane filaments are cooled in a 25°C water bath to form a film, wound and wound. Finally, the membrane filaments are immersed in ethanol at 60°C for 6 hours, and then the ethanol is washed with water to obtain a PVDF hollow fiber microfiltration membrane.

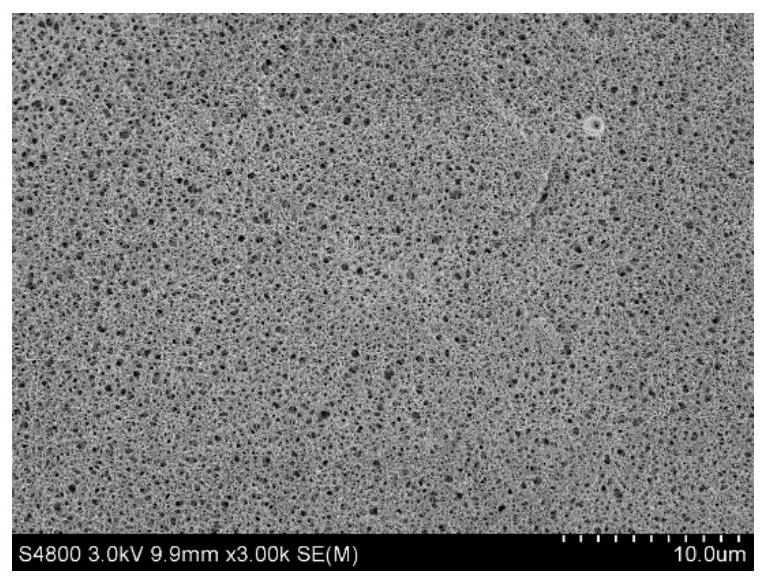

[0041] The porosity of the microfiltration membrane is 81%, the micropores with a pore d...

Embodiment 2

[0044] The operation of this embodiment is the same as that of Example 1, except that the amount of polymer PVDF is changed to 25 parts, and the amount of polychlorotrifluoroethylene is changed to 6 parts.

[0045] The porosity of the microfiltration membrane is 82%, the micropores with a pore diameter between 0.1 μm and 0.2 μm account for at least 72%, the micropores with a pore diameter between 0.01 μm and 0.1 μm account for less than 14%, and the pore diameter is between Micropores between 0.2 μm and 0.3 μm account for less than 14%.

[0046] Using a universal testing machine to test the mechanical strength of the membrane filaments, the obtained PVDF hollow fiber microfiltration membrane has a tensile strength of 8.0MPa and an elongation at break of 105%; a self-made water flux device is used to test the pure water flux under standard atmospheric pressure at 990L· m -2 h -1 .

[0047] Compared with Example 1, this embodiment changes the ratio of polyvinylidene fluoride ...

Embodiment 3

[0049] The operation of this embodiment is the same as that of Embodiment 2, except that the temperature of the die head is increased from 175° C. to 180° C.

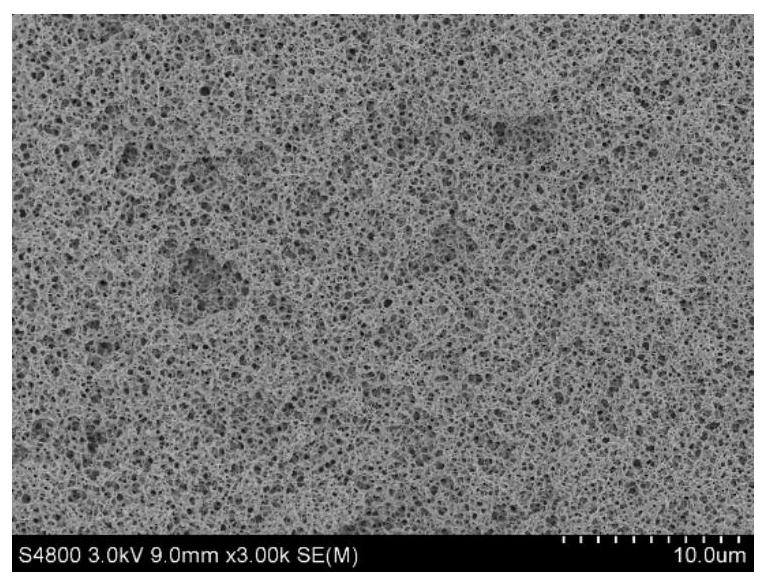

[0050] The porosity of the microfiltration membrane is 83%, the micropores with a pore diameter between 0.1 μm and 0.2 μm account for at least 70%, the micropores with a pore diameter between 0.01 μm and 0.1 μm account for less than 15%, and the pore diameter is between Micropores between 0.2 μm and 0.3 μm account for less than 15%.

[0051] Using a universal testing machine to test the mechanical strength of the membrane filaments, the obtained PVDF hollow fiber microfiltration membrane has a tensile strength of 8.1MPa and an elongation at break of 90%; a self-made water flux device is used to test the pure water flux under standard atmospheric pressure at 1600L· m -2 h -1 ,

[0052] Compared with Example 2, this example increases the temperature of the die head, and the primary film at the nozzle opening of the die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com