Integrated fin with triangular winglet

A technology of triangular winglets and fins, applied in the field of integrated heat exchange tube fins, heat exchange and heating equipment, can solve the problems of difficult and precise installation, wear and tear, etc., to reduce volume, improve assembly accuracy, and facilitate large-scale The effect of streamlined installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so that the advantages and features of the present invention are more readily understood by those skilled in the art, thereby making more clearly defined defined defined

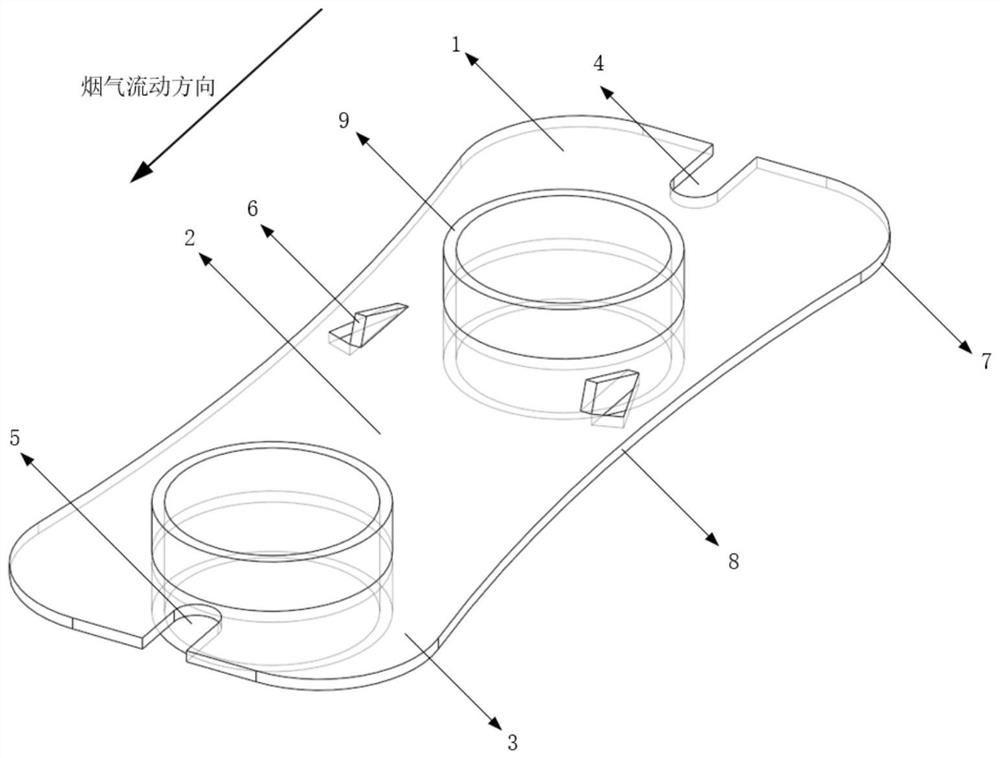

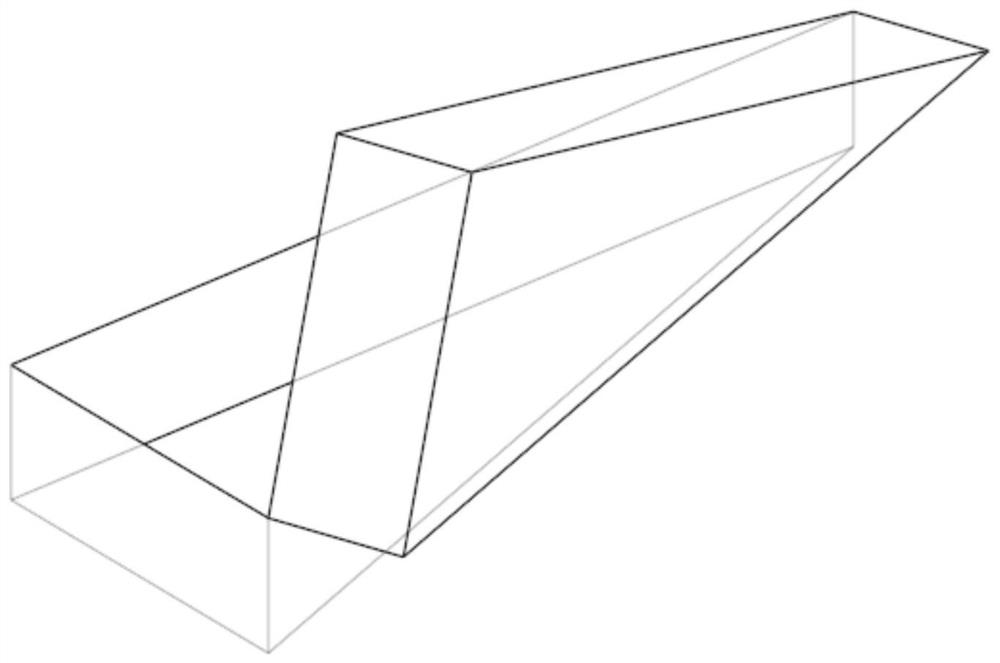

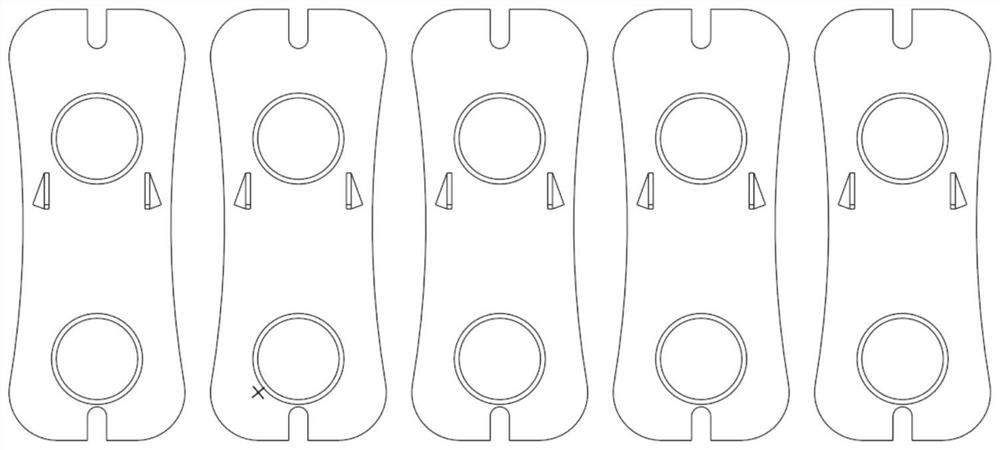

[0023] Such as figure 1 As shown, the fins on the fins, in the flue gas flow direction, there is two through holes, and two vias are opened, and the central wiring of the two base tube 9 coincides with the center axis of the fins. The front portion of the base tube 9 on the sheet is the wind wind zone 1, the region of the two base tube 9 is the heat exchange enhancement zone 2, and the rear of the rear of the base tube 9 is the back wind region 3, that is, the fins along the flue gas flow. The direction is divided into a windshield zone 1, a heat transfer enhancement zone 2, and a back wind region 3; the center of the front end of the fin is opened with a front U-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com