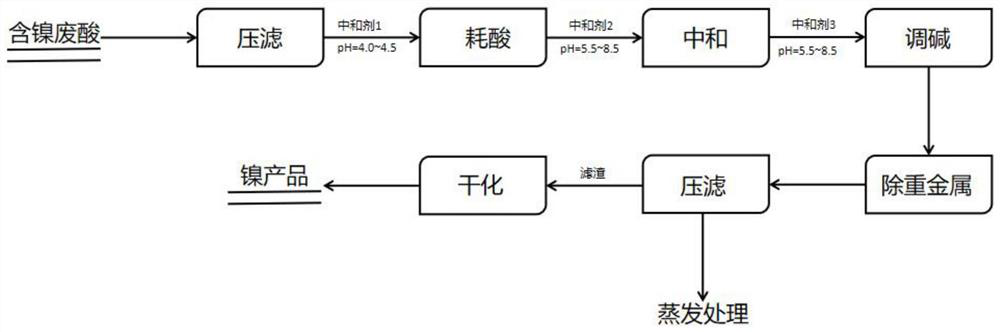

Method for recovering nickel resource in waste acid system

A resource recovery and systematic technology, applied in the direction of chemical instruments and methods, nickel compounds, metallurgical wastewater treatment, etc., can solve the problems of shortened equipment life, secondary pollution, high cost, etc., and achieve improved recovery rate, cost saving, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The waste acid system used is a phosphoric acid system with a nickel content of 9.93g / L, a total phosphorus of 2.09g / L, and an acidity (calculated as H3PO4) of 988g / L. The above-mentioned waste acid filtered through the precision filter reaches the stirring tank, slowly adds 15% milk of lime, adjusts the pH value of the feed liquid to 4.0, stirs for 20 minutes, puts it into a plate and frame filter press for pressure filtration, and obtains the filtrate A and the filter residue a. Filter residue A is processed by the Environmental Protection Agency; add 15% sodium hydroxide solution to filtrate A, adjust the pH value of the solution to 6.0, stir and react for 30 minutes, then add 15% sodium carbonate solution, adjust the pH value of the solution to 9.0, react for 30 minutes, Obtain the mixed solution; then add 10% sodium sulfide solution to the mixed solution, stir and react for 10 minutes, put it into the plate frame and press filter to obtain the filtrate B and nickel...

Embodiment 2

[0060] The waste acid system used is a nitric acid system, the nickel content is 14.7g / L, the total phosphorus is 4.12g / L, and the acidity (as HNO 3 Count) is 189g / L. The above-mentioned waste acid filtered through the precision filter reaches the stirring tank, slowly adds 15% milk of lime, adjusts the pH value of the feed liquid to 4.1, stirs for 20 minutes, puts it into a plate and frame filter press for pressure filtration, and obtains the filtrate A and the filter residue a. The filter residue A is treated by the Environmental Protection Agency; add 15% potassium hydroxide solution to the filtrate A, adjust the pH value of the solution to 8.0, stir and react for 20 minutes, then add 20% sodium bicarbonate solution, adjust the pH value of the solution to 11, and react for 30 minutes , to obtain a mixed solution; then add 15% sodium sulfide solution to the mixed solution, stir and react for 20 minutes, pour it into the plate frame and press filter to obtain filtrate B and ...

Embodiment 3

[0063] The waste acid system used is a nitric acid system, the nickel content is 18g / L, the total phosphorus is 5.65g / L, and the acidity (as HNO 3 Count) is 205g / L. Put the waste acid filtered through the precision filter into the mixing tank, slowly add 10% milk of lime, adjust the pH value of the feed liquid to 4.5, stir for 20 minutes, put it into a plate and frame filter press for pressure filtration, and obtain filtrate A and filter residue a. Treat the filter residue A by the Environmental Protection Agency; add 15% sodium hydroxide solution to the filtrate A, adjust the pH value of the solution to 7.0, stir and react for 30 minutes, then add 10% sodium bicarbonate solution, adjust the pH value of the solution to 10, and react for 20 minutes , to obtain a mixed solution; then add 15% composite alkali sulfide solution to the mixed solution, stir and react for 20 minutes, pour into the plate frame and press filter to obtain filtrate B and nickel slime, and the nickel slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com