Thermal composite underwater laser shock material surface modification method

An underwater laser and thermal composite technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as increased surface roughness, weakened structure and performance, and difficult coating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

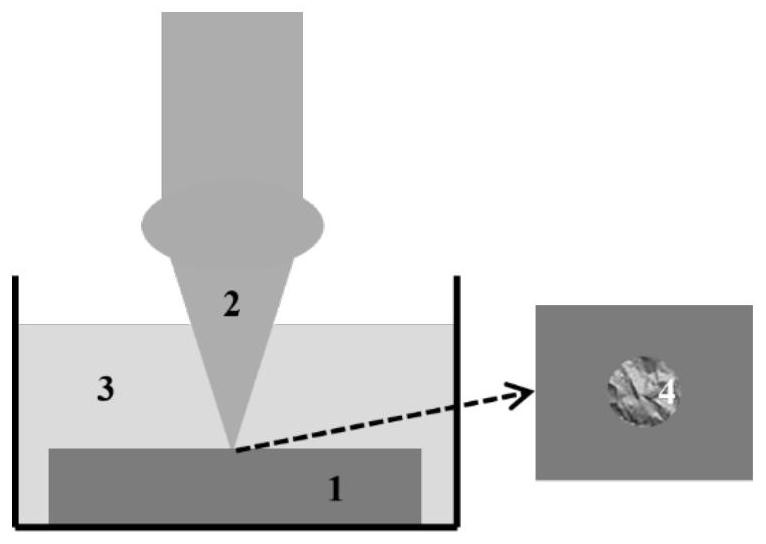

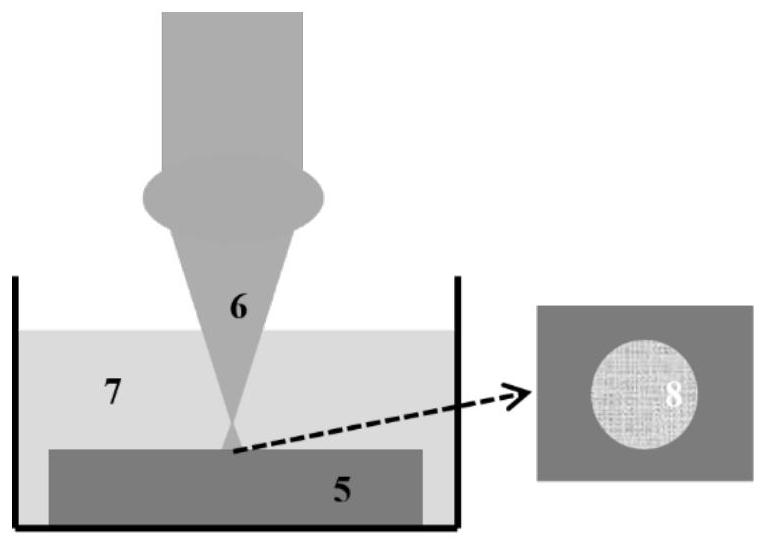

[0036] A thermal composite underwater laser shock material surface modification method, comprising steps:

[0037] (1) Build a pulse laser shock material processing platform in an underwater environment, adjust the pulse laser to a circular pulse laser beam, laser energy 6J, pulse width 18ns;

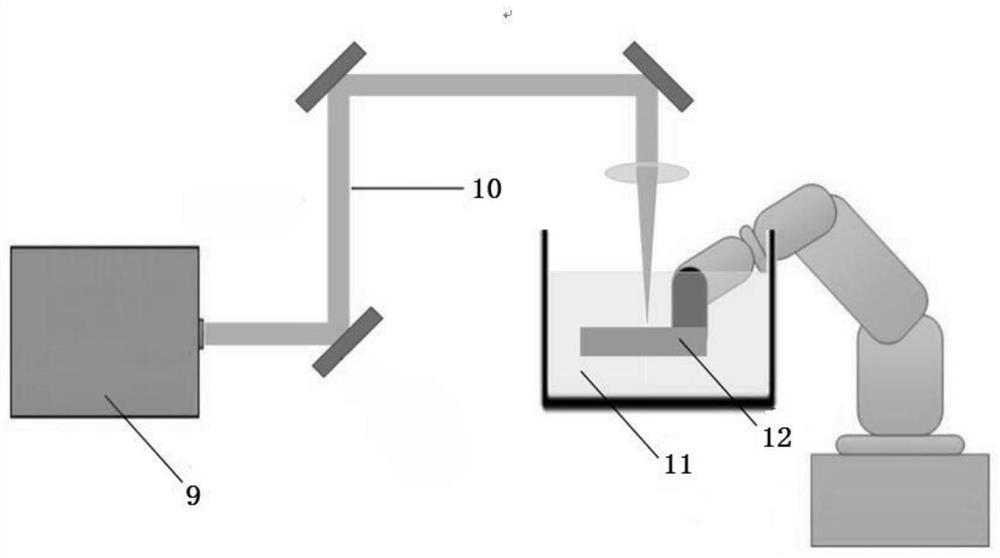

[0038] The pulsed laser shock material processing platform includes: a pulsed laser transmitter 9, an external optical path system 10, and an object-carrying device 12 for an underwater processing environment, and the underwater environment 11 is provided by deionized water.

[0039] (2) Adjust the energy distribution of the pulsed laser beam from Gaussian distribution to flat-top distribution; the specific method is as follows: emit the pulsed laser beam on the black test paper to judge the degree of ablation on the surface of the black test paper; adjust the voltage of the pulsed laser transmitter, when the black test paper If the color contrast of the white ablation area on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com