Three-axis welding strip cutter and implementation method thereof

A cutting tool and shaft welding technology, which is applied to cutting tools, manufacturing tools, and accessories of shearing machines, etc., can solve the problem of inconvenient realization of multiple sets of welding strip handling structures, unfavorable handling layout, and multiple sets of welding strips. The problem that the cutting and pulling lines cannot be carried out can achieve the effect of good cutting effect, improved efficiency and convenient cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

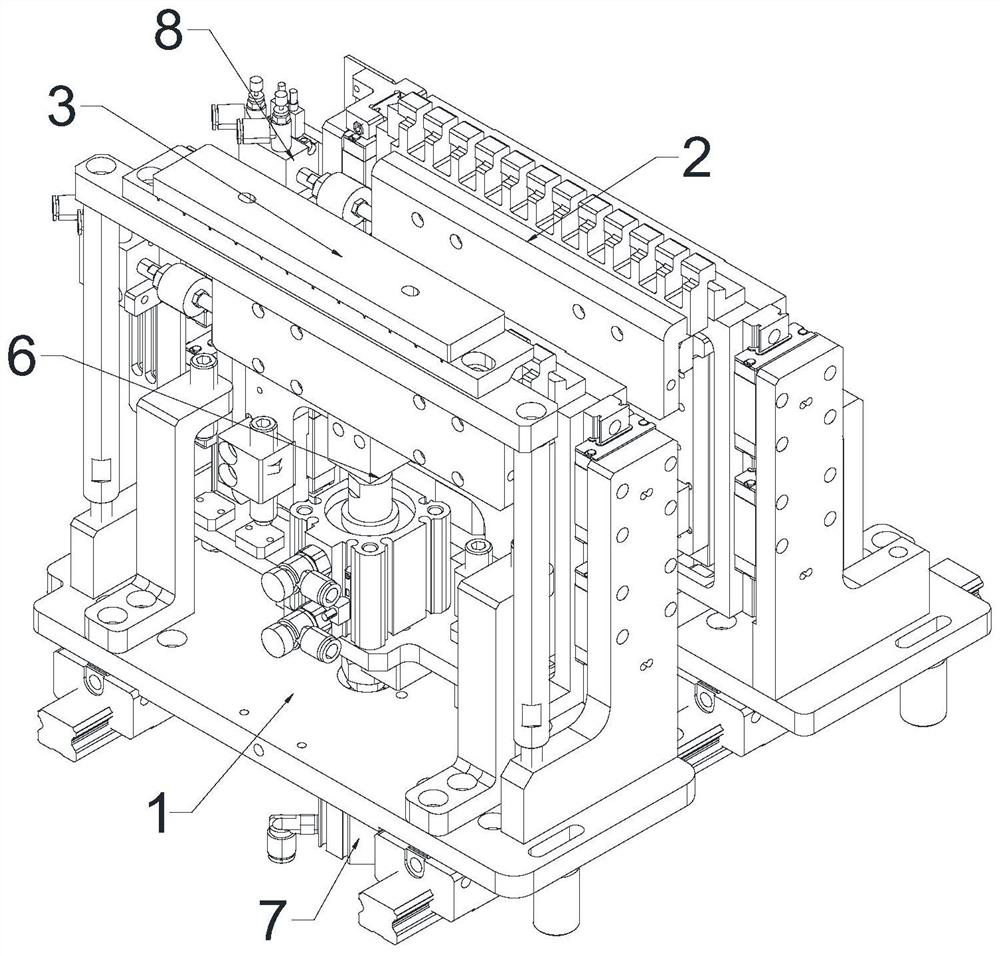

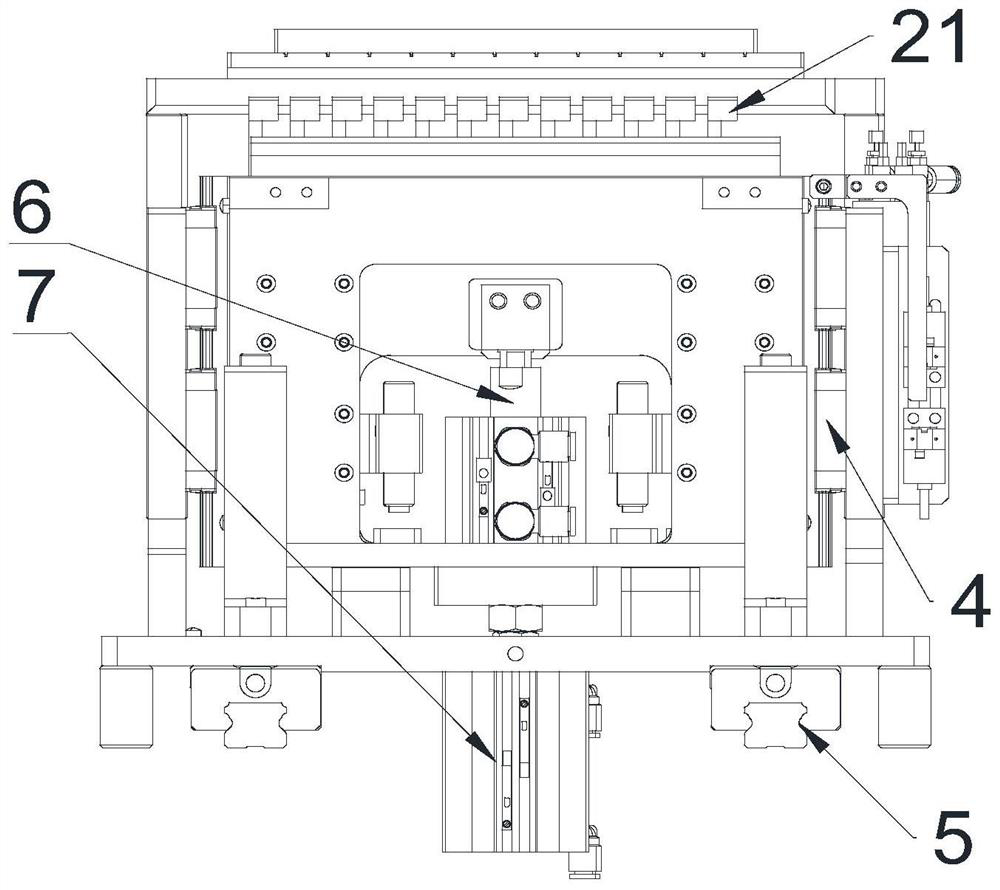

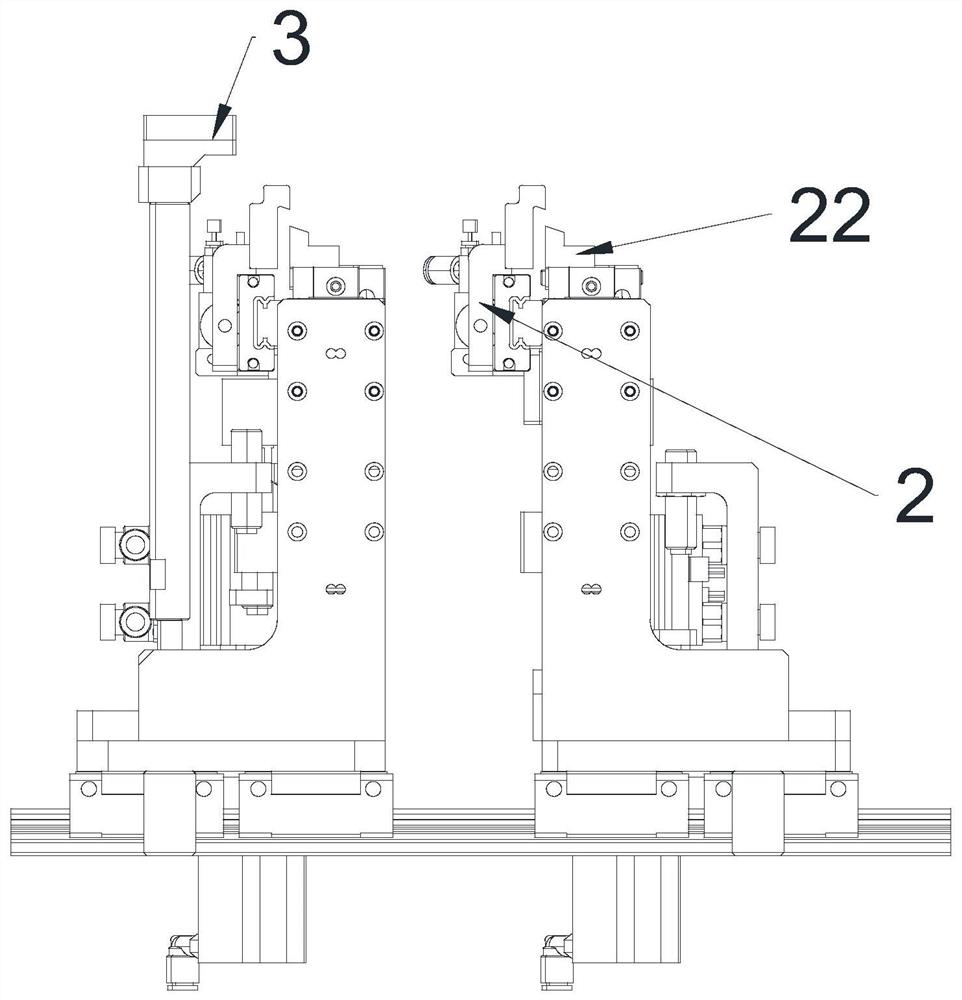

[0035] combined with Figure 1-4 , a three-axis welding ribbon tool, including a base 1, a traverse knife group 2, a wire mechanism 3, a first guide rail 4, a second guide rail 5, a cutting cylinder 6, a lifting cylinder 7, a traverse cylinder 8 and a solder ribbon 9. The base 1 is provided with a mounting block, and the mounting block is connected with other components through a bolt structure or a rivet structure.

[0036] The mounting block is fixedly connected with a traverse knife group 2, a wire mechanism 3, a first guide rail 4, a second guide rail 5, a cutting cylinder 6, a lifting cylinder 7 and a traverse cylinder 8, and the cutters of the traverse knife group 2 Multiple groups are provided with the wire mechanism 3, and the through holes matching the number of special-shaped cutters 21 are arranged on the wire mechanism 3. The through hole is used for passing the first-level limiting welding strip 9 .

[0037] The traverse knife group 2 includes a special-shaped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com