A kind of preparation method of lithium ion battery composite material with double shell structure

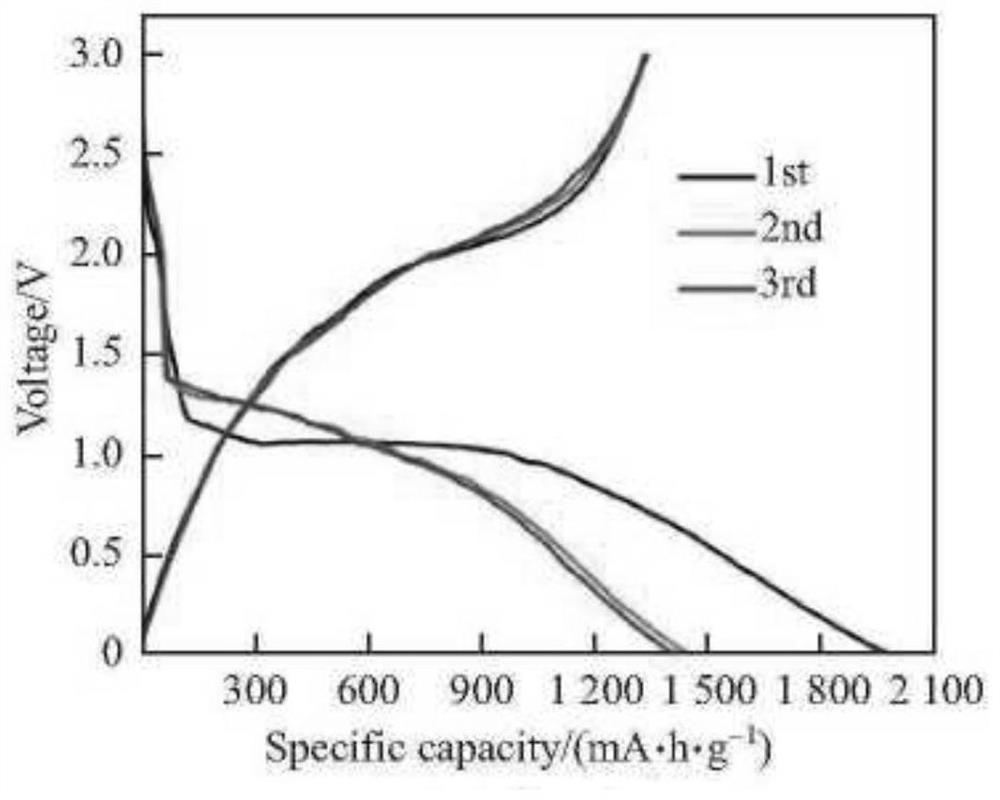

A technology of lithium-ion batteries and composite materials, which is applied in the field of preparation of lithium-ion battery composite materials, can solve the problems of poor conductivity and poor conductivity, and achieve the effects of excellent discharge specific capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of a lithium-ion battery composite material with a double-layer shell structure specifically comprises the following steps:

[0020] S1: adding cobalt nitrate hexahydrate into N,N-dimethylformamide, then ultrasonically dissolving to obtain solution I, then adding 2,5-dihydroxyterephthalic acid to anhydrous ethanol solution, ultrasonically dissolving it Dissolve to obtain solution II, mix and stir solutions I and II, add distilled water and then move to a polytetrafluoroethylene reactor, react at 110 ° C for 24 h, and cool to obtain metal organic framework Co-MOF-74, which is for later use; The mass ratio of hydrated cobalt nitrate and 2,5-dihydroxyterephthalic acid was 1.2:0.46; the volume ratio of N,N-dimethylformamide, absolute ethanol and distilled water was 15:10:1.5.

[0021] S2: adding copper nitrate trihydrate into methanol solution, adding the metal organic framework Co-MOF-74 in step S1 after ultrasonic dissolving, stirring magnetically for...

Embodiment 2

[0024] A preparation method of a lithium-ion battery composite material with a double-layer shell structure specifically comprises the following steps:

[0025] S1: adding cobalt nitrate hexahydrate into N,N-dimethylformamide, then ultrasonically dissolving to obtain solution I, then adding 2,5-dihydroxyterephthalic acid to anhydrous ethanol solution, ultrasonically dissolving it Dissolve to obtain solution II, mix and stir solutions I and II, add distilled water and then move to a polytetrafluoroethylene reaction kettle, react at 120 ° C for 30 h, and cool to obtain metal organic framework Co-MOF-74, which is for later use; The mass ratio of hydrated cobalt nitrate and 2,5-dihydroxyterephthalic acid was 2.8:0.85; the volume ratio of N,N-dimethylformamide, absolute ethanol and distilled water was 20:14:3.

[0026] S2: adding copper nitrate trihydrate into methanol solution, adding the metal organic framework Co-MOF-74 in step S1 after ultrasonic dissolving, stirring magnetical...

Embodiment 3

[0029] A preparation method of a lithium-ion battery composite material with a double-layer shell structure specifically comprises the following steps:

[0030] S1: adding cobalt nitrate hexahydrate into N,N-dimethylformamide, then ultrasonically dissolving to obtain solution I, then adding 2,5-dihydroxyterephthalic acid to anhydrous ethanol solution, ultrasonically dissolving it Dissolve to obtain solution II, mix and stir solutions I and II, add distilled water and then move to a polytetrafluoroethylene reactor, react at 115 ° C for 26 h, and cool to obtain metal organic framework Co-MOF-74, which is for later use; The mass ratio of hydrated cobalt nitrate and 2,5-dihydroxyterephthalic acid was 1.8:0.54; the volume ratio of N,N-dimethylformamide, absolute ethanol and distilled water was 16:12:1.9.

[0031] S2: adding copper nitrate trihydrate into methanol solution, adding the metal organic framework Co-MOF-74 in step S1 after ultrasonic dissolving, stirring magnetically for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com