Preparation method of high-capacity and high-stability lithium ion battery negative electrode material

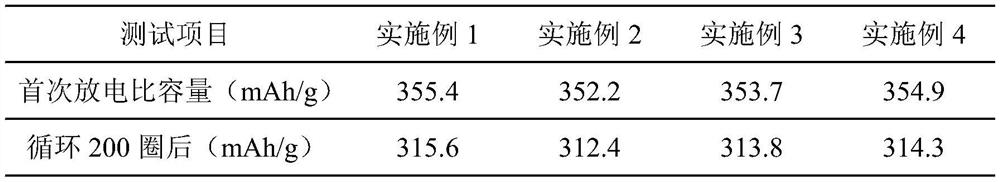

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of reduced charge and discharge efficiency, reduced battery reversible capacity, material volume expansion, etc., and achieve excellent discharge specific capacity , the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for preparing a high-capacity, high-stability lithium-ion battery negative electrode material, specifically comprising the following steps:

[0013] S1: Petroleum coke was first heat-treated at 300°C for 3 hours, and then pulverized. The particle size of the pulverized powder was kept at 5 μm, and the obtained product was used in the next step.

[0014] S2: Then mix the product in step S1 with sodium peroxide or potassium peroxide, stir at room temperature for 0.5 h, then add distilled water so that the solid mixture can be prepared into a slurry, react for 2 h, then dry the solid, and Put it into a tube furnace, conduct a second heat treatment at 700°C for 10 hours under air conditions, and set aside for later use, wherein the mass ratio of the product in step S1 to sodium peroxide or potassium peroxide is 1:0.06.

[0015] S3: The product obtained in step S2 is subjected to graphitization treatment, graphitized and calcined at 2500° C. under atmospheric condit...

Embodiment 2

[0017] A method for preparing a high-capacity, high-stability lithium-ion battery negative electrode material, specifically comprising the following steps:

[0018] S1: Petroleum coke was first heat-treated at 350°C for 6 hours, and then pulverized. The particle size of the pulverized powder was kept at 10 μm, and the obtained product was used in the next step.

[0019] S2: Then mix the product in step S1 with sodium peroxide or potassium peroxide, stir at room temperature for 2 hours, then add distilled water so that the solid mixture can be prepared into a slurry, react for 4 hours, then dry the solid, and add In a tube furnace, under air conditions, conduct a second heat treatment at 800° C. for 15 hours, and set aside, wherein the mass ratio of the product in step S1 to sodium peroxide or potassium peroxide is 2:0.09.

[0020] S3: The product obtained in step S2 is subjected to graphitization treatment, graphitized and calcined at 3000° C. under atmospheric conditions for ...

Embodiment 3

[0022] A method for preparing a high-capacity, high-stability lithium-ion battery negative electrode material, specifically comprising the following steps:

[0023] S1: Petroleum coke was first heat-treated at 320°C for 4 hours, and then pulverized. The particle size of the pulverized powder was kept at 6 μm, and the obtained product was used in the next step.

[0024] S2: Then mix the product in step S1 with sodium peroxide or potassium peroxide, stir at room temperature for 1 hour, then add distilled water so that the solid mixture can be prepared into a slurry, react for 3 hours, then dry the solid, and add In a tube furnace, under air conditions, conduct a second heat treatment at 750° C. for 12 hours, and set aside, wherein the mass ratio of the product in step S1 to sodium peroxide or potassium peroxide is 1.3:0.07.

[0025] S3: The product obtained in step S2 is subjected to graphitization treatment, graphitized and calcined at 2700° C. for 17 hours, then cooled, ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com