Epitaxial growth method, epitaxial structure and photoelectric device

A technology of epitaxial growth and epitaxial structure, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve problems such as hindering device performance, achieve the effects of improving crystal quality, suppressing interface fluctuations, and reducing twinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

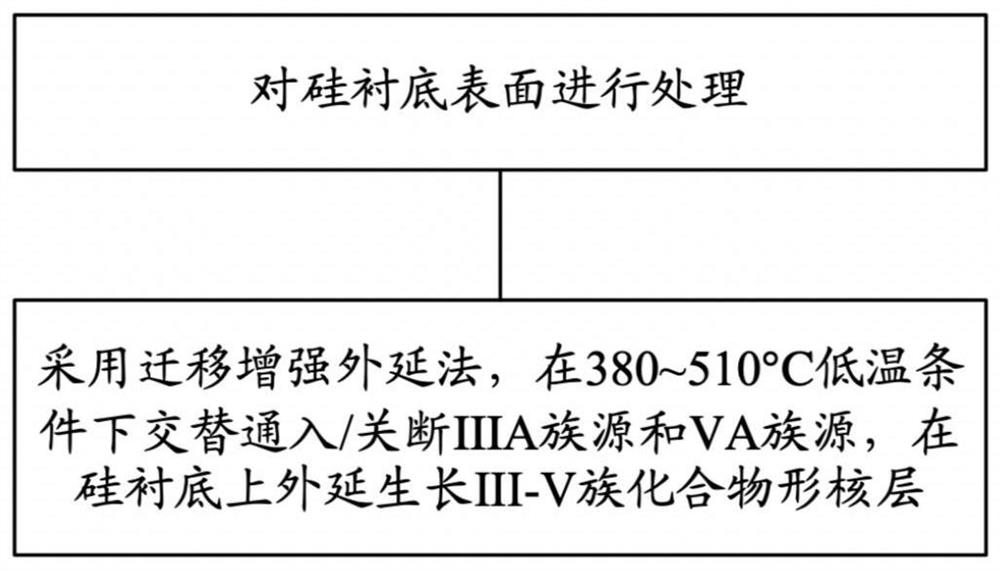

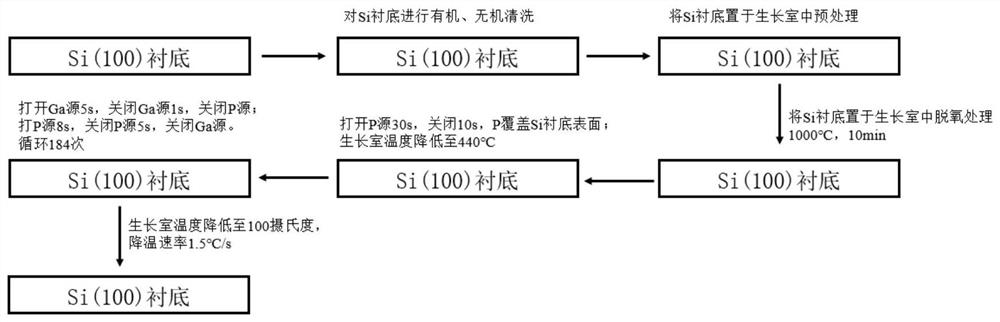

[0088] ginseng figure 2 As shown, the epitaxial growth method in this embodiment is to epitaxially grow a GaP thin film on a Si (100) substrate, which specifically includes the following steps:

[0089] 1. Treat the surface of the Si substrate.

[0090] 1.1. Clean the surface of the Si substrate.

[0091] First wash with acetone, isopropanol, and deionized water to remove organic matter on the substrate surface; then use NH 4 OH, H 2 o 2 , HCL, and deionized water for alkali cleaning and pickling; finally, HF and deionized water are used to remove surface oxides and organic matter; the cleaned Si substrate is cleaned with high-purity N 2 blow dry.

[0092] 1.2. Perform degassing pretreatment on the surface of the Si substrate.

[0093] The cleaned Si substrate is sent to the molecular beam epitaxy sample chamber for pre-degassing for 30 minutes; then sent to the pretreatment chamber for degassing at 300°C for 1.5 hours, and then sent to the growth chamber after degassin...

Embodiment 2

[0110] The epitaxial growth method in this embodiment is to epitaxially grow a GaP film on a Si(100) substrate, which specifically includes the following steps:

[0111] 1. Treat the surface of the Si substrate.

[0112] 1.1. Clean the surface of the Si substrate.

[0113] First wash with acetone, isopropanol, and deionized water to remove organic matter on the substrate surface; then use NH 4 OH, H 2 o 2 , HCL, and deionized water for alkali cleaning and pickling; finally, HF and deionized water are used to remove surface oxides and organic matter; the cleaned Si substrate is cleaned with high-purity N 2 blow dry.

[0114] 1.2. Perform degassing pretreatment on the surface of the Si substrate.

[0115] The cleaned Si substrate is sent to the molecular beam epitaxy sample chamber for pre-degassing for 30 minutes; then sent to the pretreatment chamber for degassing at 300°C for 1.5 hours, and then sent to the growth chamber after degassing is completed.

[0116] 1.3. Deoxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com