Butterfly-shaped optical cable photoelectric hybrid cable with double-side-by-side structure and preparation method thereof

A technology of optoelectronic hybrid cable and butterfly optical cable, which is applied in the direction of fiber mechanical structure, cable/conductor manufacturing, power cable including optical transmission components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

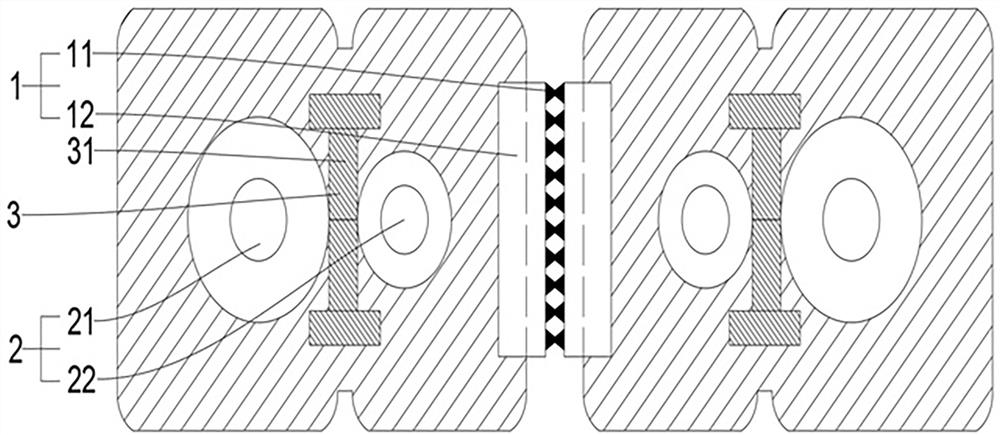

[0030] Such as figure 1 As shown, a double-side-by-side structure bow-shaped optical fiber hybrid cable includes a tearing structure 1, and a photoelectric hybrid part 2 that is symmetrically arranged on the vertical plane where the tearing structure 1 is located; the photoelectric hybrid part 2 includes An optical cable unit 21 and a cable unit 22; one end of the optical cable unit 21 is fixedly connected to the tearing structure 1, and the other end is connected to the cable unit 22 through a fixing member 3; the cable unit 22 is far away from the The tearing structure 1 described above is set;

[0031] The tearing structure 1 includes a tearing tooth 11 and a blocking strip 12; one side of the blocking strip 12 is provided with a plurality of tearing teeth 11; the tearing tooth 11 is opposite to the blocking strip 12 The symmetrical setting of the horizontal plane where it is located;

[0032] The barrier strips 12 are arranged symmetrically relative to the vertical plane...

Embodiment 2

[0043] The photoelectric hybrid cable includes the following raw materials by weight: 30 parts of binary ethylene propylene rubber, 20 parts of polypropylene, 2 parts of dicumyl peroxide, 10 parts of white carbon black, 2 parts of polytetrafluoroethylene Vinyl fluoride and 15 parts of sodium stearate; the particle diameter of each of the raw materials is 2mm, and the heating and melting temperature is set to 300°C, and all the other steps are the same as in Example 1.

Embodiment 3

[0045] The photoelectric hybrid cable includes the following raw materials by weight: 40 parts of binary ethylene propylene rubber, 25 parts of polypropylene, 3 parts of dicumyl peroxide, 15 parts of white carbon black, 5 parts of polytetrafluoroethylene Vinyl fluoride and 20 parts of sodium stearate; the particle diameter of each of the raw materials is 15 mm, and the heating and melting temperature is set to 350 ° C, and the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com