Microtopography rapid measurement method suitable for white light scanning interference

A micro-topography, white light scanning technology, applied in the field of precision optical measurement engineering, can solve the problems of large algorithm error and inability to realize the three-dimensional topography of the measurement system, and achieve the effects of high accuracy, reduced overall running time, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

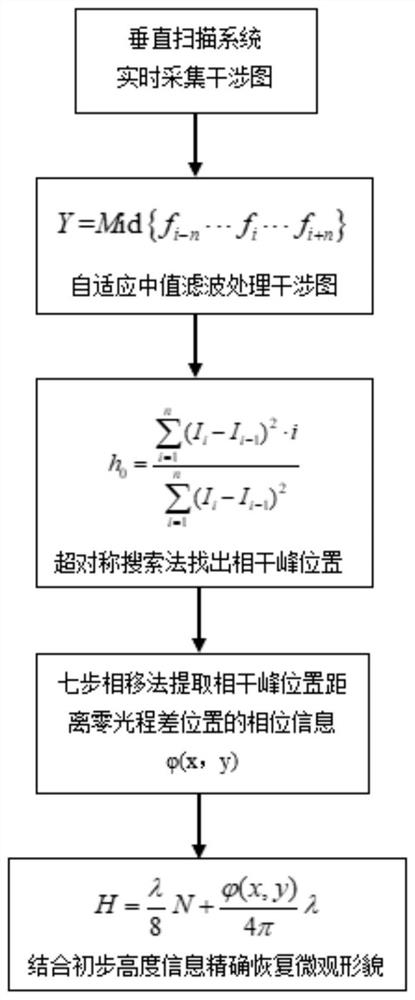

[0039] Combine Figure 1 to 4 A rapid measurement method for micro-morphology applicable to white light scanning interference. During the experiment, the optical system is equipped with an interference mirror system with a magnification of 20 x, and a light source uses a white LED having a center wavelength of 532 nm, and a filter is selected by a filter. The 10 nm short-phase dry light is detected to the mobile phone tempered film sample, and 32 interference images are collected in the range of 2.13 μm in the range of 2.13 μm according to the step size of λ / 8. A micro-morphological rapid measurement method suitable for use in white light scanning interference is:

[0040] Step 1, combined figure 2 The optical path structure shown, connects the light source and the lighting system, adjusting the spatial position of the lighting system and the first splitter to undete the lighting system by the first splitter and reflect, adjust the position of the objective lens system, so that b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com