Coal-fired unit shutdown optimization control method and control device

A coal-fired unit, optimized control technology, applied in the direction of control system, water supply control, steam boiler components, etc., can solve the problems of power plant power consumption rate increase, unfavorable sustainable development, increase production cost, etc., to achieve reduction The power consumption rate of the plant is conducive to sustainable development and the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

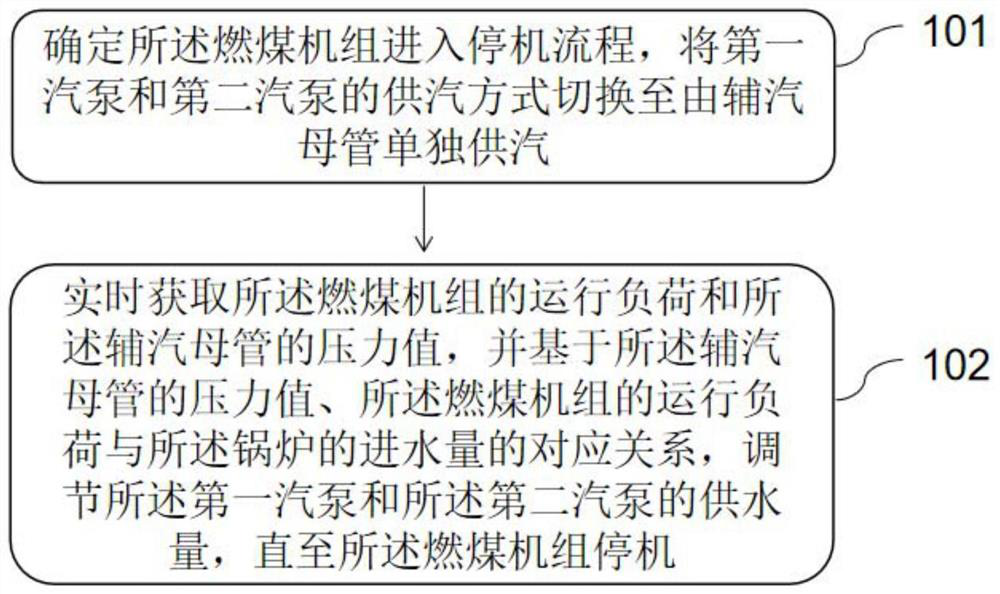

[0095] This embodiment provides an optimal control method for shutting down of a coal-fired unit without an electric pump. The unit includes a first steam pump, a second steam pump, and an electric pump. The electric pump is used as a backup. To supply water to the boiler in case of abnormality, the specific operation steps are as follows:

[0096] The power plant duty chief applies to the provincial commissioner for the shutdown process, and after the provincial dispatcher agrees to shut down, it is confirmed that the coal-fired unit enters the shutdown process;

[0097] Obtain the temperature value and pressure value of the auxiliary steam main pipe. At this time, the temperature value of the auxiliary steam main pipe is greater than or equal to 250°C, and the pressure is stable at 0.5-0.6MPa, and the steam supply mode of the steam turbine is converted to the auxiliary steam main pipe alone. , cut off the gas supply pipeline of the four-stage extraction main pipe, and the sp...

Embodiment 2

[0103] In this embodiment, two 50% capacity steam pumps and one 35% capacity electric pump are set in the power plant as an example. When the normal electric pump is used to stop, the number of starts and stops is 18 times, and the unit can be obtained in the coal-burning bunker. The running time and power consumption of the electric pump during the shutdown process under the two conditions of non-burning and non-burning coal bunkers are shown in Table 1 below:

[0104]

[0105] Table 1 Running time and power consumption of the electric pump during shutdown

[0106] After adopting the non-electric pump shutdown method provided by the present invention, relevant data collection is carried out, and the data comparison table of the two shutdown modes of non-electric pump shutdown and electric pump shutdown can be obtained, as shown in Table 2 below:

[0107]

[0108]

[0109] Table 2 Data comparison table of two shutdown modes

[0110] From the parameters in Table 2, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com