Lysimachia christinae Hance fiber antibacterial textile fabric and preparation method thereof

A technology of textile fabrics and money grass, which is applied in the field of textiles, can solve the problems of easy breeding of bacteria and poor antibacterial effect, and achieve the effects of low washing size shrinkage, good antibacterial effect and long-lasting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

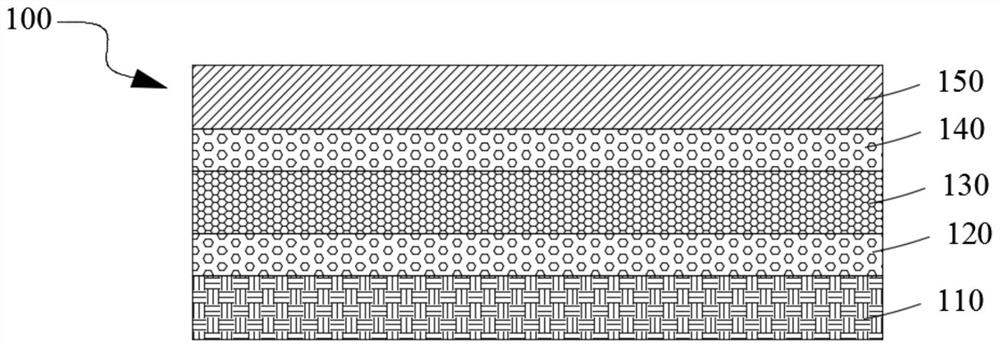

[0076] Such as Figure 9 to Figure 10 As shown, in another specific embodiment disclosed by the present invention, the antibacterial fabric 210 can be, for example, polyquaternium / aloe antibacterial fiber, and the polyquaternium / aloe antibacterial fiber is composed of polyquaternium and aloe The extract spinning solution is obtained by spinning, which has the effects of acne removal, anti-inflammatory and antibacterial. The present invention discloses a preparation method for preparing the polyquaternium / aloe antibacterial fiber as described above, including but not limited to the following steps:

[0077] —S301, providing a spinning solution, the spinning slurry comprises the following components by weight:

[0078] Carboxymethyl chitosan 3-10% by weight, polyquaternium 0.01-0.1% by weight, aloe extract 15-30% by weight, polyvinyl alcohol 10-50% by weight, sulfonate 1.5-5% by weight, alcohol 3-10% by weight and the balance of deionized water;

[0079] —S302, stirring and mi...

Embodiment 1

[0142] This embodiment discloses a method for preparing a desmodium fiber antibacterial textile fabric, comprising the following steps:

[0143] 1) Preparation of desmodium fiber: making cellulose pulp, adding caustic soda to the cellulose pulp, aging, and then yellowing with carbon disulfide, then adding dry desmodium grass powder, porous starch, xanthan gum, mixing evenly, dissolving caustic soda, aging, wet method Spinning, post-processing, and drying to obtain desmodium fiber; wherein, the weight ratio of cellulose pulp to caustic soda and carbon disulfide is 100:9:7. The mass ratio of cellulose pulp to dry grass powder, porous starch and xanthan gum is 100:25:12:6.

[0144] 2) Bamboo fiber, cotton fiber, polyester filament fiber and desmodium fiber are blended into yarns, warped by sections to make weaving shafts, sizing is carried out with composite antibacterial slurry, dried, and produced on a shuttle loom Desmodium desmodium fiber fabric gray cloth; and then through ...

Embodiment 2

[0155] This embodiment discloses a method for preparing a desmodium fiber antibacterial textile fabric, comprising the following steps:

[0156] 1) Preparation of desmodium fiber: making cellulose pulp, adding caustic soda to the cellulose pulp, aging, and then yellowing with carbon disulfide, then adding dry desmodium grass powder, porous starch, xanthan gum, mixing evenly, dissolving caustic soda, aging, wet method Spinning, post-processing, drying, to obtain desmodium fiber; wherein, the weight ratio of cellulose pulp to caustic soda and carbon disulfide is 100:9:7; The mass ratio is 100:30:15:8.

[0157] 2) Bamboo fiber, cotton fiber, polyester filament fiber and desmodium fiber are blended into yarns, warped by sections to make weaving shafts, sizing is carried out with composite antibacterial slurry, dried, and produced on a shuttle loom Desmodium desmodium fiber fabric gray cloth; and then through fabric pre-finishing, printing and dyeing treatment and post-finishing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com