A Shallow Treatment Process Applicable to SPHC Low Carbon Series Steels

A treatment process and a series of technologies, applied in the field of shallow treatment process, can solve the problems of shortening the refining time of LF, difficulty in making white slag and adjusting slag, reducing costs and energy consumption, and achieving shortening of refining and soft blowing time, extension of floating time, The effect of reducing electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A shallow treatment process suitable for SPHC low-carbon series steel grades of the present invention mainly lies in optimizing the pretreatment of molten steel in the tapping process to form yellow and white slag, and performing shallow treatment on the pretreated molten steel in the LF refining furnace to achieve The purpose of shortening the LF refining time. Include the following steps:

[0048] S1. Hot metal pretreatment: The hot metal is desulfurized and slag-removed through the KR desulfurization station, so that the sulfur content of the hot metal is ≤0.015%.

[0049] S2. Converter smelting: Put the molten iron treated in step S1 into a converter for smelting.

[0050] S3. Converter end point control: The converter end point control temperature is 1643°C, the sub-lance fixed carbon is 0.045%, and the free oxygen of molten steel is 687ppm.

[0051] S4. Pretreatment of molten steel in converter tapping process:

[0052] During the tapping process, 409kg of Al-M...

Embodiment 2~ Embodiment 4

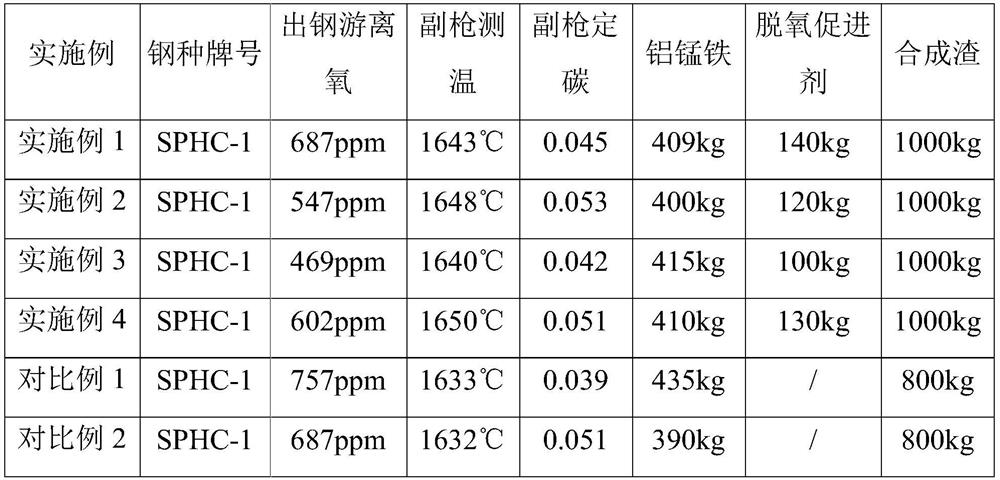

[0066] The process steps are the same as in Example 1, except that the converter endpoint control and LF refining furnace process parameters are fine-tuned, and the specific parameters are shown in Table 1 and Table 3.

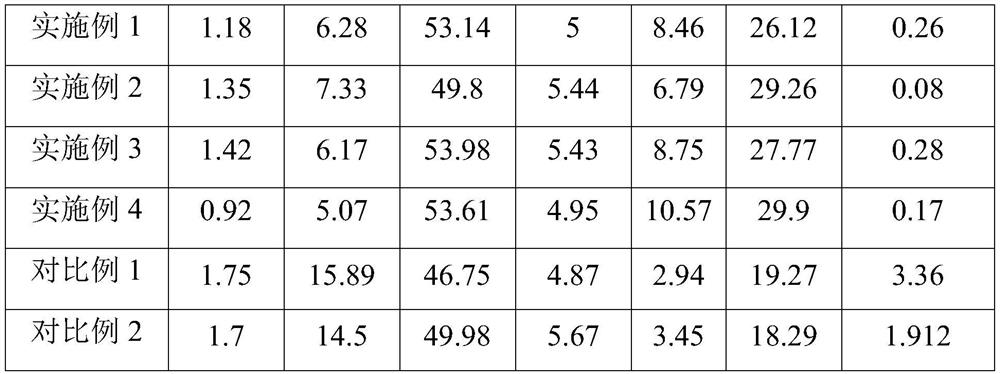

[0067] After the converter treatment in Examples 1 to 4, the slag sample entering the station of the LF refining furnace has formed alkaline slag, that is, reducing slag, SiO 2 The content is significantly reduced, the total iron content in the slag is less than 1.5%, and yellow and white slag has been formed. The specific slag sample composition is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com