IF steel hot-dip galvanized steel plate with low delta r value and preparation method of IF steel hot-dip galvanized steel plate

A hot-dip galvanized steel sheet and hot-dip galvanizing technology, applied in the field of metallurgy, can solve problems that need to be further improved, and achieve the effects of low cost, simple preparation process, and low energy consumption production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a method for preparing a low Δr value IF steel hot-dip galvanized steel sheet, comprising the following steps:

[0017] (1) Smelting process: according to the chemical composition of the IF steel, it is smelted into a slab, and the thickness of the slab is 200mm;

[0018] (2) Hot rolling process: heat the cast slab to 1110°C-1150°C, stay in the furnace for 200-260 minutes, and then carry out rough rolling. The rough rolling adopts 5-pass rolling, and the entire length of the phosphorus is removed, and the rolling process is put into use Insulation cover, the thickness of the middle slab after rough rolling is 39mm~43mm; after rough rolling, finish rolling is carried out, the starting temperature of finish rolling is 910°C~940°C, the temperature of finish rolling is 770°C~800°C; after finish rolling, it is naturally cooled to 610~ Coil at 650°C to obtain hot-rolled coils. At this time, the thickness of the steel plate is 3.5mm;

[0019] (3) Pickli...

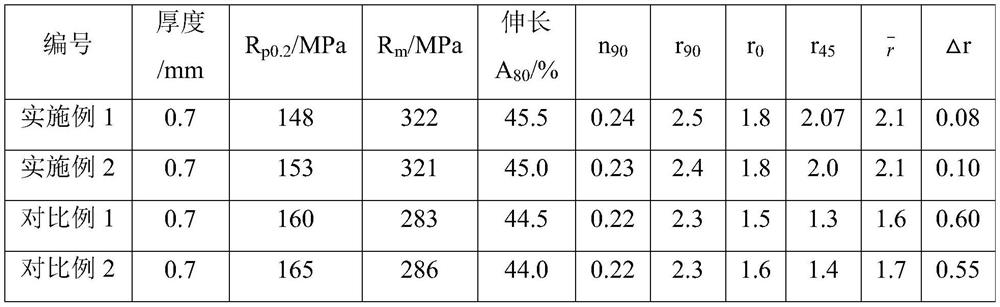

Embodiment

[0036] The present invention will be further explained and illustrated by the following examples and comparative examples.

[0037] The following examples and comparative examples are smelted into slabs according to the chemical composition of Table 1, and the slab thickness is 200mm;

[0038] The billet is heated and rough rolled after 255 minutes of furnace time. The rough rolling adopts 5-pass rolling, and the phosphorus is completely removed in the whole length. The rolling process uses a heat preservation cover, and the thickness of the middle slab after rough rolling is 42.0mm;

[0039] After the rough rolling, the slab is subjected to finish rolling, and after the finish rolling, it is naturally cooled to the coiling temperature for coiling to obtain a steel plate with a thickness of 3.5mm;

[0040] After pickling the hot-rolled coils, they are cold-rolled into thin steel strips, and the cold-rolling reduction ratio is 80.0%;

[0041] Finally, the IF steel hot-dip galv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com