Method for preparing high-strength and high-plasticity titanium-graphene composite material based on graded compounding

A composite material, graphene technology, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve problems such as high strength and low plasticity, and achieve the effect of strong plastic matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

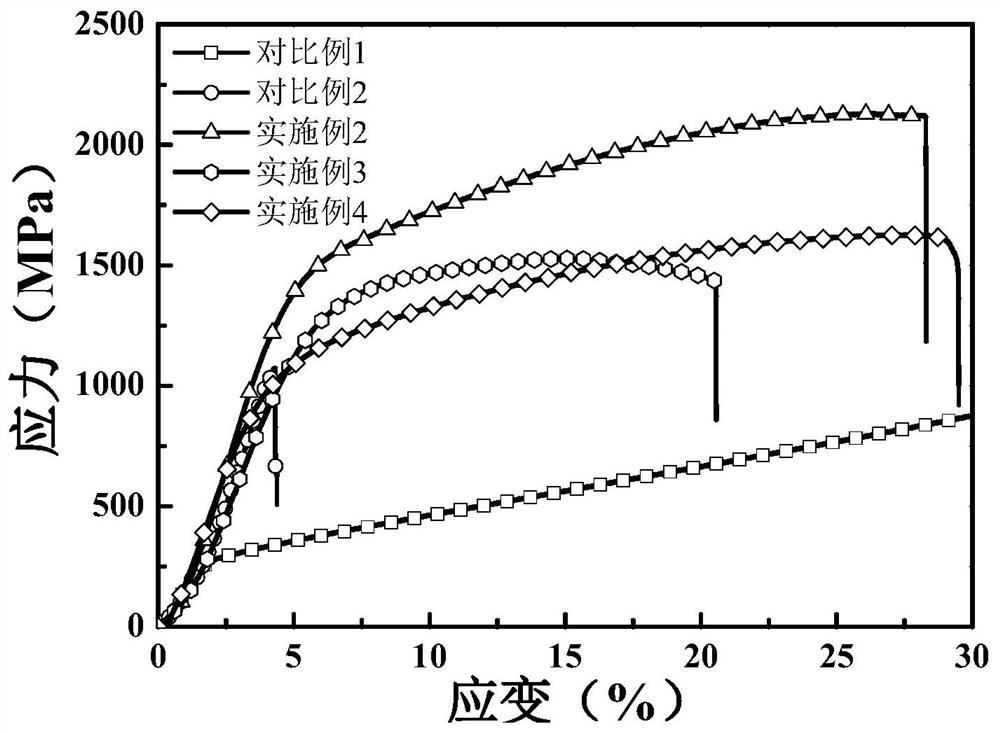

Embodiment 1

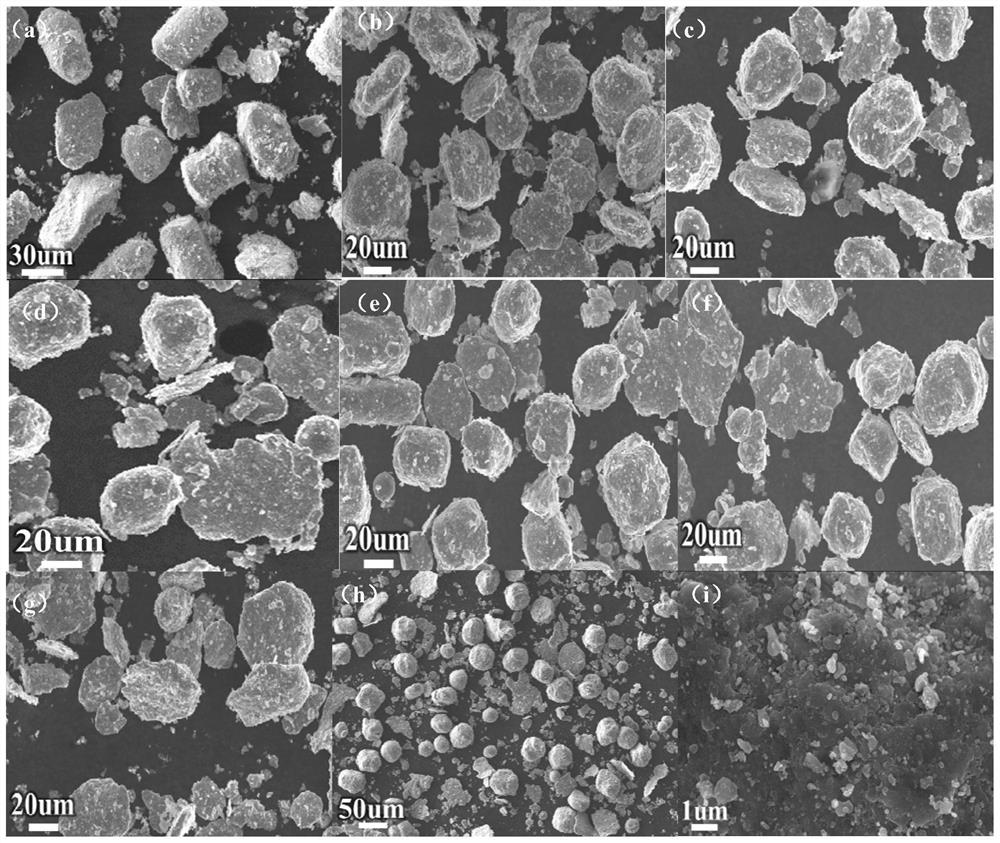

[0017] Weigh 0.1g of graphene microflakes with a diameter of 1μm and 100g of TC4 powder with a particle diameter of 200 mesh, put the graphene microflakes or TC4 powder into a ball mill in two steps for ball milling, and fill the ball mill with argon for protection , using alcohol as a process control agent;

[0018] In the first step of ball milling, put 50g of TC4 powder and all the graphene microflakes into a stainless steel ball mill jar, and perform ball milling on a planetary mill for 120 minutes; the balls are tungsten carbide balls, and the diameters of the tungsten carbide balls are 8mm respectively , 5mm, 2mm, the mass ratio is 5:3:2, the ball-material ratio is 20:1, and the speed is 300r / min.

[0019] In the second step of ball milling, wait for the stainless steel tank to cool down, add the remaining 50g of TC4 powder to the mixed powder obtained in the first step of ball milling, continue ball milling for 120min to obtain a heterogeneously dispersed titanium-graph...

Embodiment 2

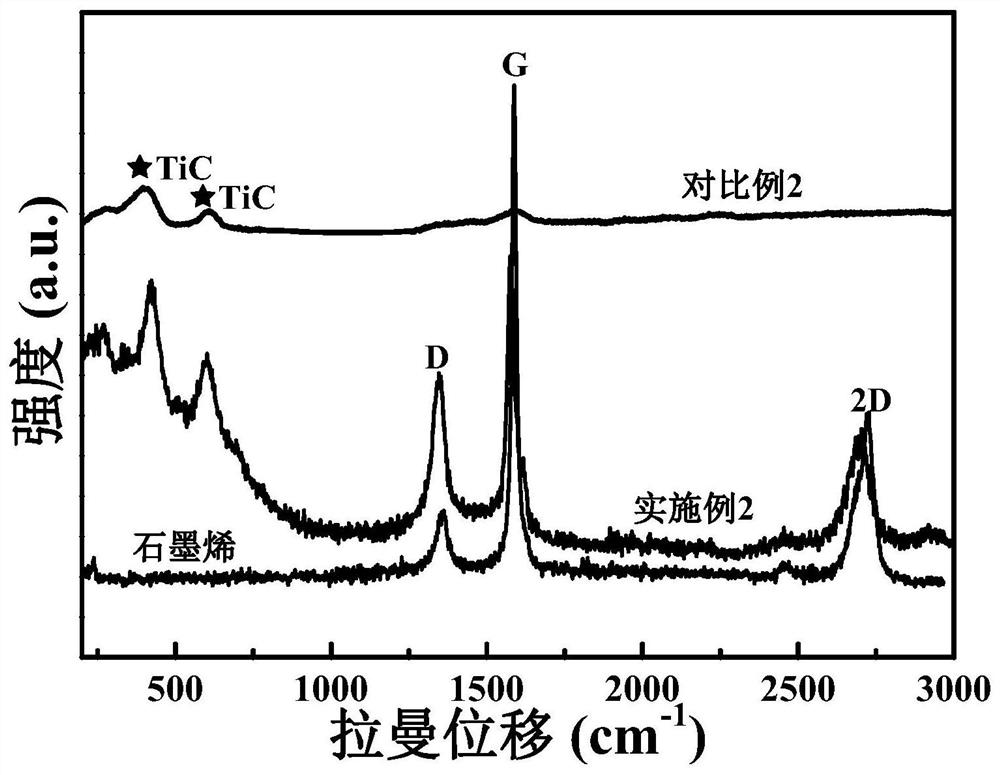

[0021] Weigh 0.5g of graphene microflakes with a sheet diameter of 3μm and 100g of Ti powder with a particle size of 500 mesh respectively, put the graphene microflakes or Ti powder into a ball mill in two steps for ball milling, and fill the ball mill with argon for protection , using alcohol as a process control agent;

[0022] In the first step of ball milling, put 80g of Ti powder and all the graphene microflakes into a stainless steel ball mill jar, and perform ball milling on a planetary mill for 240 minutes; the balls are tungsten carbide balls, and the diameters of the tungsten carbide balls are 8mm , 5mm, 2mm, the mass ratio is 5:3:2, the ball-material ratio is 10:1, and the speed is 300r / min.

[0023] In the second step of ball milling, when the stainless steel tank is cooled, add the remaining 20g of Ti powder to the mixed powder obtained in the first step of ball milling, and continue ball milling for 60 minutes to obtain a heterogeneously dispersed titanium-graphe...

Embodiment 3

[0025] Weigh 0.3g of graphene microflakes with a diameter of 2μm and 100g of Ti powder with a particle diameter of 500 mesh respectively, put the graphene microflakes or Ti powder into a ball mill in two steps for ball milling, and fill the ball mill with argon gas for protection , using alcohol as a process control agent;

[0026] In the first step of ball milling, put 0.15g of graphene microflakes and all Ti powder into a stainless steel ball mill jar, and perform ball milling on a planetary mill for 240 minutes; the balls are tungsten carbide balls, and the diameters of tungsten carbide balls are respectively 8mm, 5mm, 2mm, the mass ratio is 5:3:2, the ball-material ratio is 10:1, and the speed is 300r / min.

[0027] During the second step of ball milling, when the stainless steel tank is cooled, add the remaining 0.15g of graphene microflakes to the mixed powder obtained in the first step of ball milling, and continue ball milling for 60 minutes to obtain a heterogeneously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com