Comprehensive recovery method for valuable metals in lead-zinc smelting acid mud

A technology of valuable metals and recycling methods, applied in the direction of element selenium/tellurium, process efficiency improvement, etc., can solve problems such as mercury pollution, achieve high purity, clean and environmentally friendly process, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

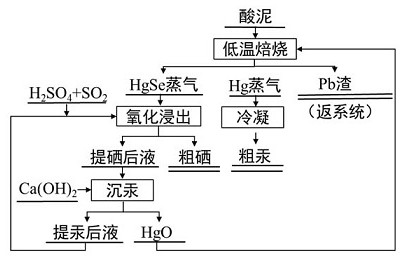

Method used

Image

Examples

Embodiment 1

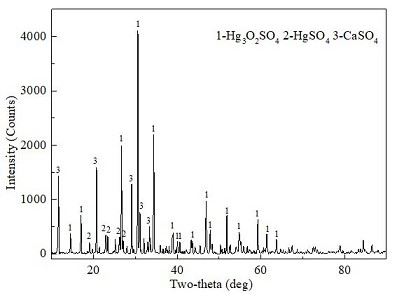

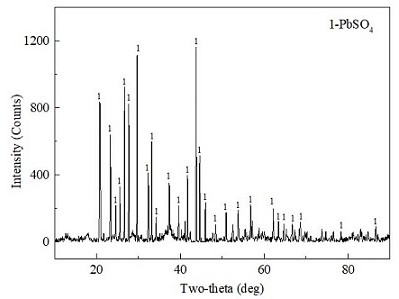

[0042] The main phases of lead-zinc smelting acid mud include lead sulfate, mercury sulfide, mercury selenide, and mercury chloride, with a water content of 18.40%. It contained 22.04% lead on a dry basis, 1.29% mercury, 1.59% selenium and 717.8g / t silver.

[0043] (1) The lead-zinc smelting acid mud is subjected to fire roasting treatment, the fire roasting method is microwave heating, the temperature is 400 ° C, the holding time is 20 minutes, and the air is passed during roasting. After roasting, easy-to-handle mercury-containing phases and residual lead-silver slag are obtained. After analysis, the lead content in the residual lead and silver slag is 96.06%, and the silver content is 1205.5g / t.

[0044] (2) The easy-to-handle mercury-containing phase is condensed in stages to obtain a crude mercury and a second-stage selenium-mercury material respectively. Mercury content in crude mercury: 99.9%.

[0045](3) The sulfuric acid solution added with potassium permanganate i...

Embodiment 2

[0048] The main phases of lead-zinc smelting acid mud include lead sulfate, mercury sulfide, mercury selenide, and mercury chloride. The water content is 27%. It contained 41% lead on a dry basis, 22% mercury, 4% selenium and 900g / t silver.

[0049] (1) The lead-zinc smelting acid mud is subjected to fire roasting treatment. The fire roasting method is microwave heating, the temperature is 600 ° C, the holding time is 40 minutes, and oxygen is passed through during roasting. After roasting, easy-to-handle mercury-containing phases and residual lead-silver slag are obtained. After analysis, the lead content in the residual lead and silver slag is 97.4%, and the silver content is 1600g / t.

[0050] (2) The easy-to-handle mercury-containing phase is condensed in stages to obtain a crude mercury and a second-stage selenium-mercury material respectively. Mercury content in crude mercury: 99.9%.

[0051] (3) The sulfuric acid solution added with potassium permanganate is used for...

Embodiment 3

[0055] The main phases of lead-zinc smelting acid mud include lead sulfate, mercury sulfide, mercury selenide, and mercury chloride. The water content is 37.74%. The dry basis contained 62.76% lead, 43.88% mercury, 6.89% selenium and 1120.2g / t silver.

[0056] (1) The lead-zinc smelting acid mud is subjected to fire roasting treatment. The fire roasting method is microwave heating, the temperature is 800°C, the holding time is 60 minutes, and oxygen is passed through during roasting. After roasting, easy-to-handle mercury-containing phases and residual lead-silver slag are obtained. After analysis, the lead content in the residual lead and silver slag is 96.06%, and the silver content is 1881.5g / t.

[0057] (2) The easy-to-handle mercury-containing phase is condensed in stages to obtain a crude mercury and a second-stage selenium-mercury material respectively. Mercury content in crude mercury: 99.9%.

[0058] (3) The sulfuric acid solution added with potassium permanganate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com