A kind of waterborne epoxy coating and its preparation method and application

A water-based epoxy and coating technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor anti-corrosion ability, inability to actively protect, poor corrosion resistance of water-based epoxy coatings, etc., to achieve cost Low, natural and non-toxic ingredients, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

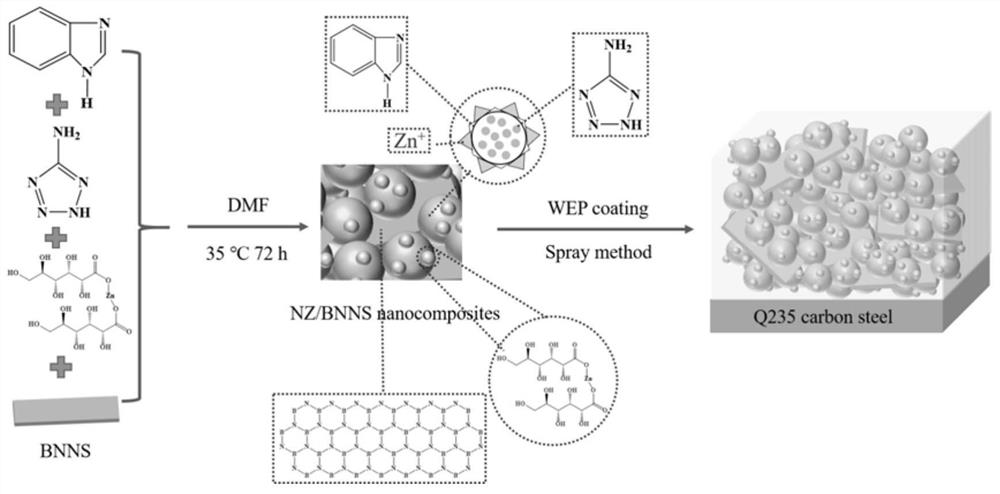

[0036] A corrosion-resistant waterborne epoxy coating, the preparation steps of which are as follows:

[0037] (1) Add 1 g of boron nitride to 180 ml of DMF, ultrasonicate the mixture at 50° C. for 4 h, centrifuge, filter, wash, and dry the centrifuged suspension to obtain boron nitride nanosheets (BNNS);

[0038] (2) Add 2g of zinc gluconate, 0.6g of 5-aminotetrazole, 1.5g of benzimidazole, 0.1g of BNNS prepared in step (1) into 180ml of DMF solution, stir at 35°C for 72h, centrifuge and filter , washing, and drying to obtain composite nanofiller 5-ATZ@ZIF-7@BNNS;

[0039] (3) Add the nanocomposite nanofiller prepared in step (2) into the water-based epoxy resin, and prepare an epoxy resin coating with a mass fraction of 0.05%.

Embodiment 2

[0041] A corrosion-resistant epoxy coating, the preparation steps of which are as follows:

[0042] (1) Add 1 g of boron nitride to 180 ml of DMF, ultrasonicate the mixture at 50° C. for 4 h, centrifuge, filter, wash, and dry the centrifuged suspension to obtain boron nitride nanosheets (BNNS);

[0043] (2) Add 2g of zinc gluconate, 0.6g of 5-aminotetrazole, 1.5g of benzimidazole, 0.1g of BNNS prepared in step (1) into 180ml of DMF solution, stir at 35°C for 72h, centrifuge and filter , washing, and drying to obtain composite nanofiller 5-ATZ@ZIF-7@BNNS;

[0044] (3) Add the nanocomposite filler prepared in step (2) into the water-based epoxy resin, and prepare an epoxy resin coating with a mass fraction of 0.1%.

Embodiment 3

[0046] A corrosion-resistant epoxy coating, the preparation steps of which are as follows:

[0047](1) Add 1 g of boron nitride to 180 ml of DMF, ultrasonicate the mixture at 50° C. for 4 h, centrifuge, filter, wash, and dry the centrifuged suspension to obtain boron nitride nanosheets (BNNS);

[0048] (2) Add 2g of zinc gluconate, 0.6g of 5-aminotetrazole, 1.5g of benzimidazole, 0.1g of BNNS prepared in step (1) into 180ml of DMF solution, stir at 35°C for 72h, centrifuge and filter , washing, and drying to obtain composite nanofiller 5-ATZ@ZIF-7@BNNS;

[0049] (3) Add the nanocomposite nanofiller prepared in step (2) into the water-based epoxy resin, and prepare an epoxy resin coating with a mass fraction of 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com