Secondary composite modifier with antibacterial property and application of secondary composite modifier in coating modified filler

A compound modifier and antibacterial technology, applied in the field of powder coating preparation, can solve the problems of high cost and weak antibacterial properties of powder coatings, and achieve the effects of improved effect, short sterilization time, and improved antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

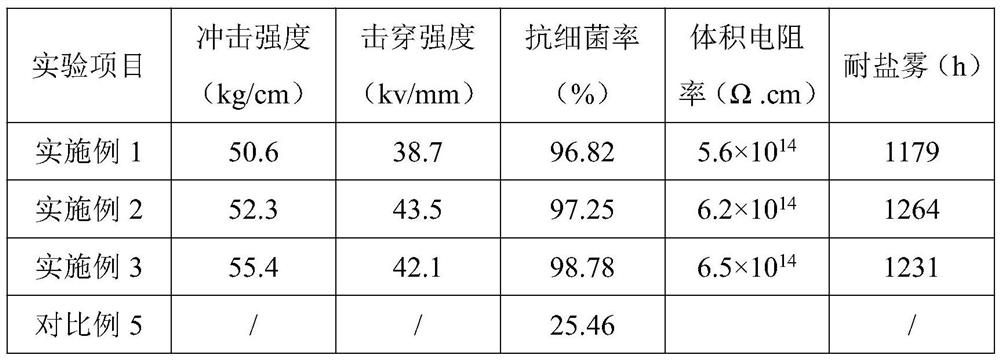

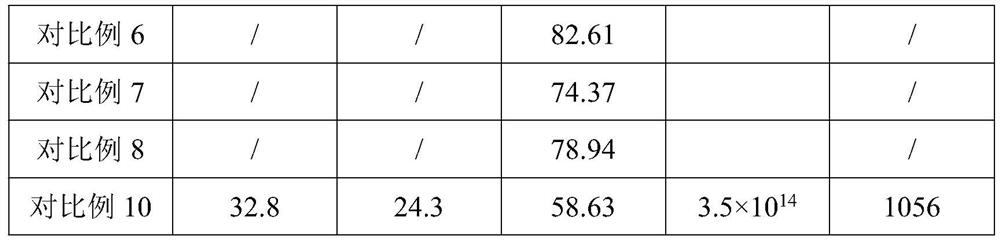

Examples

preparation example Construction

[0033] The preparation method of described modified coal ash comprises the following steps:

[0034] Step 1: pickling the coal ash with hydrochloric acid with a mass concentration of 29.1% until the pH value of the coal ash is 8.9, and then washing the acid-washed coal ash with water. After the water washing, the coal ash is tested to have a pH value of 7.4 and then press-filtered into clean coal ash, which is dried at a temperature of 75°C until the water content is 1.7%;

[0035] Step 2: Grinding the clean coal ash obtained in step 1, and sieving to obtain clean coal ash larger than 400 meshes;

[0036] Step 3: Add a primary compound modifier to the clean coal ash obtained in step 2. The primary compound modifier consists of coconut oil fatty acid diacetamide, hexaglycerol monostearate, N-oleoyl -N-Methyl taurate sodium composition, the addition of the primary compound modifier is 4.7% of the clean coal ash quality, the coconut oil fatty acid diacetamide, hexaglycerol monos...

Embodiment 1

[0043] A production process for electrical insulating powder coatings, comprising the following steps:

[0044] a. Mixing of raw materials: All kinds of raw materials are mixed according to mass percentage, then added to the mixer respectively, then pre-crushed for 1 minute, and then mixed for 4 minutes to obtain uniformly mixed raw materials;

[0045] Various raw materials are as follows by mass percentage: modified coal ash 35.8%, epoxy resin 49.8%, curing agent 8.9%, accelerator 0.2%, leveling agent 1.7%, benzoin 0.8%, defoamer 0.9%, dispersant 0.5% %, Brightener 0.8%, Pigment 0.6%.

[0046] The epoxy resin is hydrogenated bisphenol A epoxy resin ST-3000.

[0047] Described curing agent is BTDA curing agent.

[0048] The accelerator is 2-methylimidazole.

[0049] The leveling agent is PV88 leveling agent.

[0050] The defoamer is polyoxyethylene polyoxypropanolamine ether defoamer.

[0051] The dispersant is dispersant NC.

[0052] The brightener is 701B brightener.

...

Embodiment 2

[0068] A production process for electrical insulating powder coatings, comprising the following steps:

[0069] a. Mixing of raw materials: All kinds of raw materials are mixed according to mass percentage, then added to the mixer respectively, then pre-crushed for 1 minute, and then mixed for 4 minutes to obtain uniformly mixed raw materials;

[0070] Various raw materials are as follows by mass percentage: modified coal ash 38.1%, epoxy resin 48.8%, curing agent 8.8%, accelerator 0.1%, leveling agent 1.7%, benzoin 0.4%, defoamer 0.6%, dispersant 0.3% %, Brightener 0.8%, Pigment 0.4%.

[0071] The epoxy resin is hydrogenated bisphenol A epoxy resin ST-3000.

[0072] Described curing agent is BTDA curing agent.

[0073] The accelerator is 2-methylimidazole.

[0074] The leveling agent is PV88 leveling agent.

[0075] The defoamer is polyoxyethylene polyoxypropanolamine ether defoamer.

[0076] The dispersant is dispersant NC.

[0077] The brightener is 701B brightener. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com