Auxiliary shaping device for arc-shaped tempered glass production and implementation method thereof

A tempered glass and shaping device technology, which is applied in glass forming, glass tempering, glass manufacturing equipment, etc., can solve the problems of easily scalded operators, and achieve the effect of reducing the risk of being scalded and reducing the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

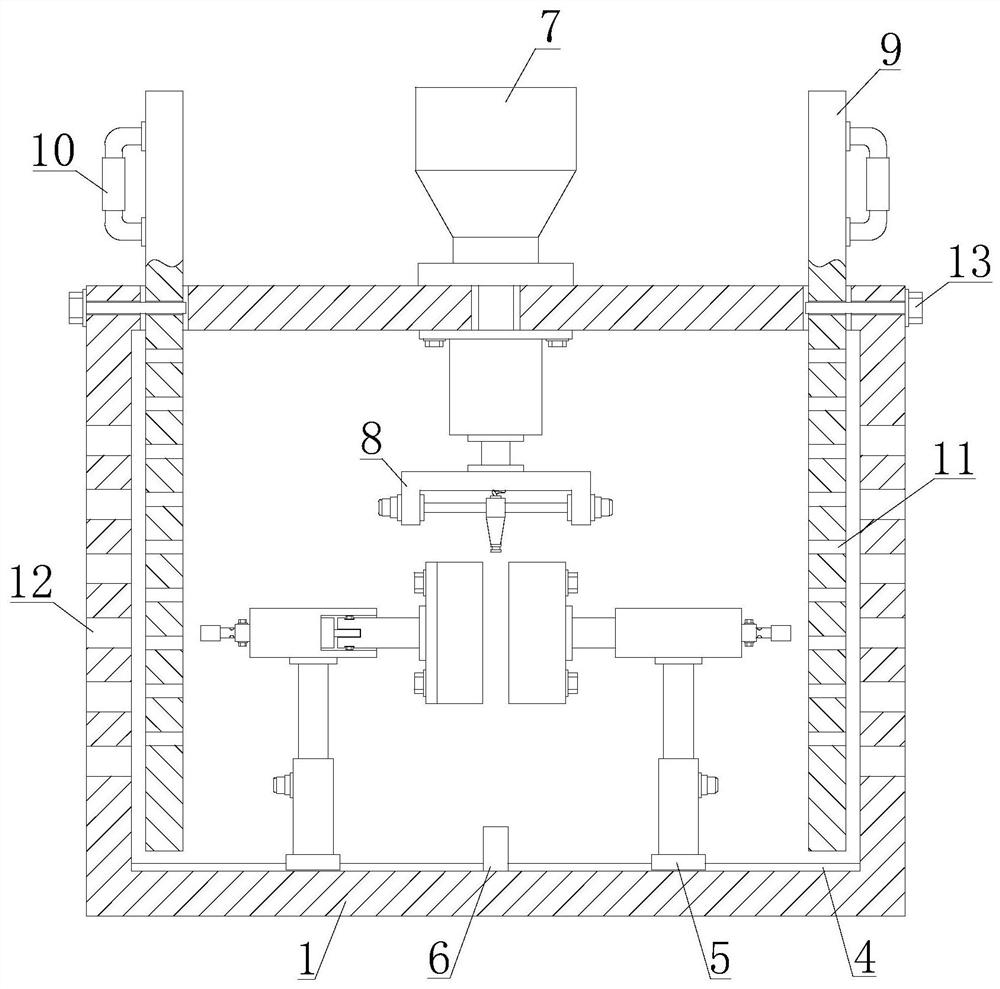

[0031] In order to better demonstrate the implementation process of the auxiliary shaping device for the production of curved tempered glass, this embodiment now proposes an implementation method of the auxiliary shaping device for the production of curved tempered glass, including the following steps:

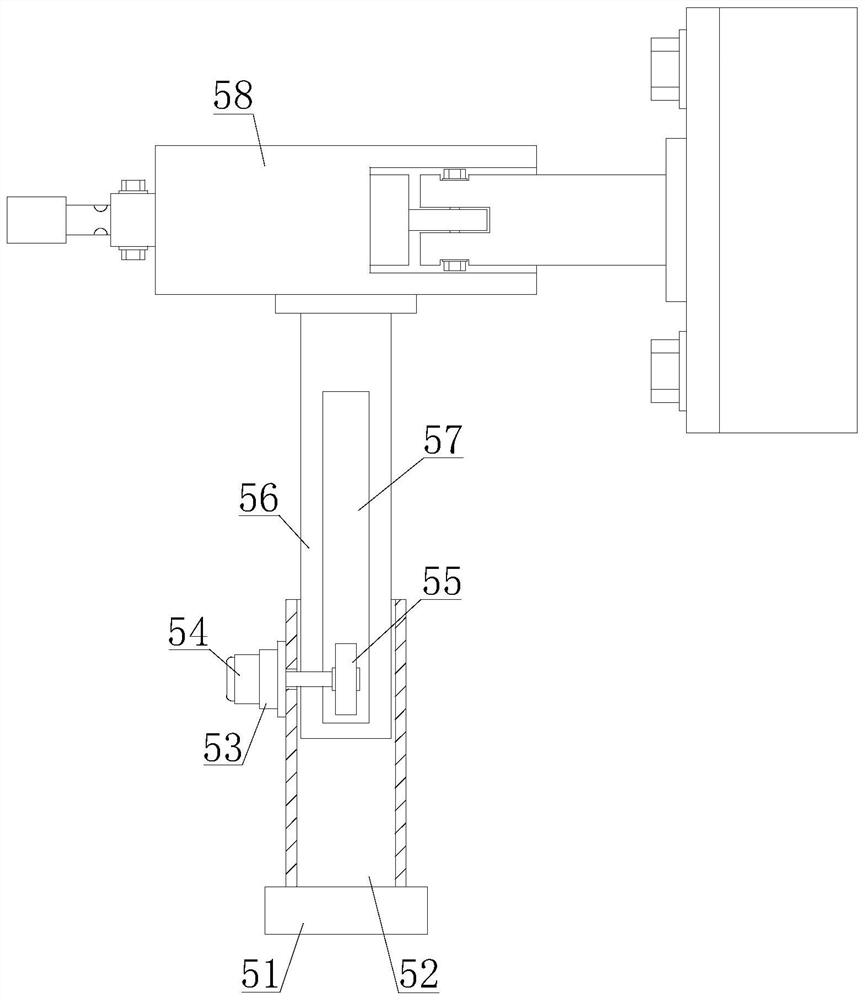

[0032] Step 1: Adjust the position of the positioning thimble 583 according to the actual size of the arc-shaped glass mold, and use the adjustment shaft 5810 to adjust the orientation angle of the movable rod 5811 and the mold splint 5812;

[0033] Step 2: install the curved glass forming mold between the mold splints 5812 on the left and right sets of auxiliary shaping brackets 5, and fix them with splint bolts 5813;

[0034] Step 3: adjust the horizontal slider 51 at the bottom of the auxiliary shaping bracket 5, so that the two groups of auxiliary shaping brackets 5 move inward to the best position, thereby clamping the curved glass mold;

[0035] Step 4: Add hot glass liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com