Bearing pressing plate assembly error preventing method for automobile motor production line

A bearing pressing plate and motor bearing technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of cumbersomeness, employee burns, forgetting to assemble, etc., improve production quality and efficiency, reduce the risk of being burned, The effect of improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

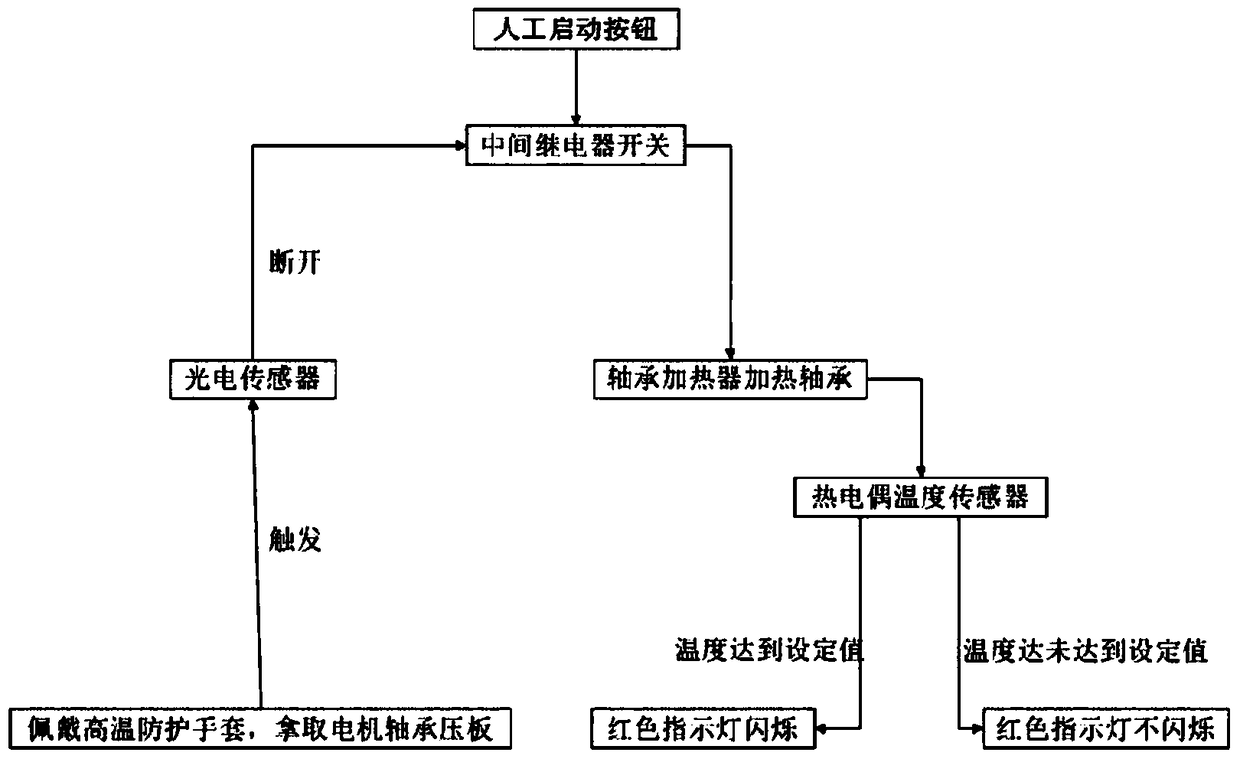

[0024] Such as figure 1 As shown, the error-proofing method for assembly of the bearing pressure plate of the automobile motor production line includes the following steps:

[0025] Manually start the intermediate relay switch button of the bearing heater, and turn on the bearing heater to start heating the bearing. After the intermediate relay switch is manually pressed, it cannot bounce back and is always on;

[0026] When the bearing heater heats the bearing, the temperature of the bearing heating is identified by the thermocouple temperature sensor. When the bearing temperature reaches the set temperature required by the bearing heater, the thermocouple temperature sensor transmits the signal to the red indicator light to flash. When the bearing temperature When the set temperature require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com