Automatic equipment for drying potato slices

An automation equipment and potato chip technology, which is applied in applications, food processing, metal processing, etc., can solve problems such as waste, achieve good economic benefits, improve operation results, and reduce the risk of being scalded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

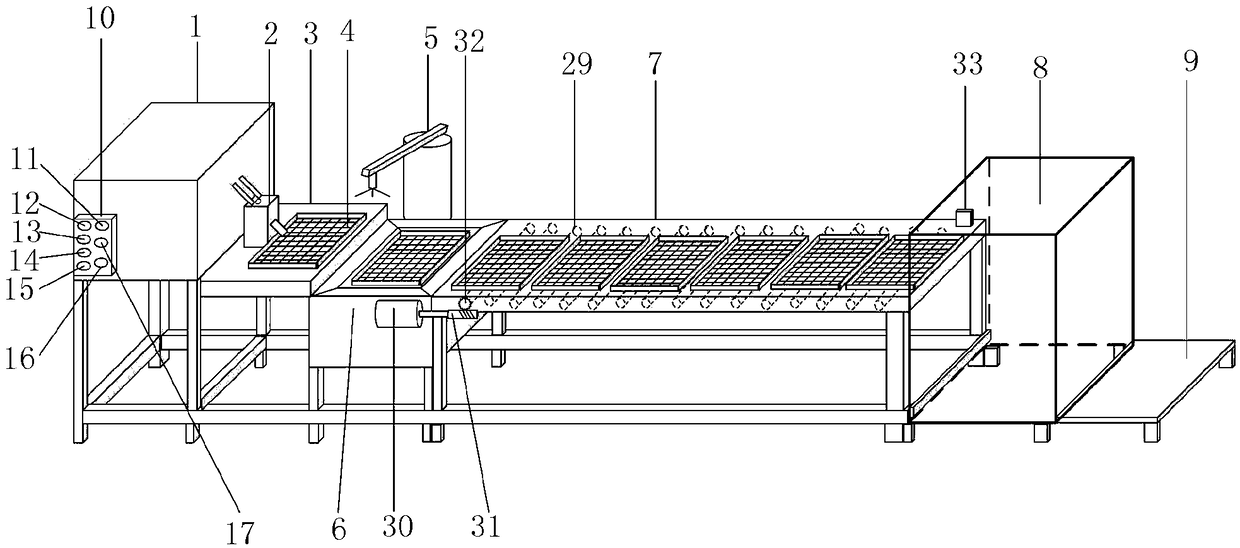

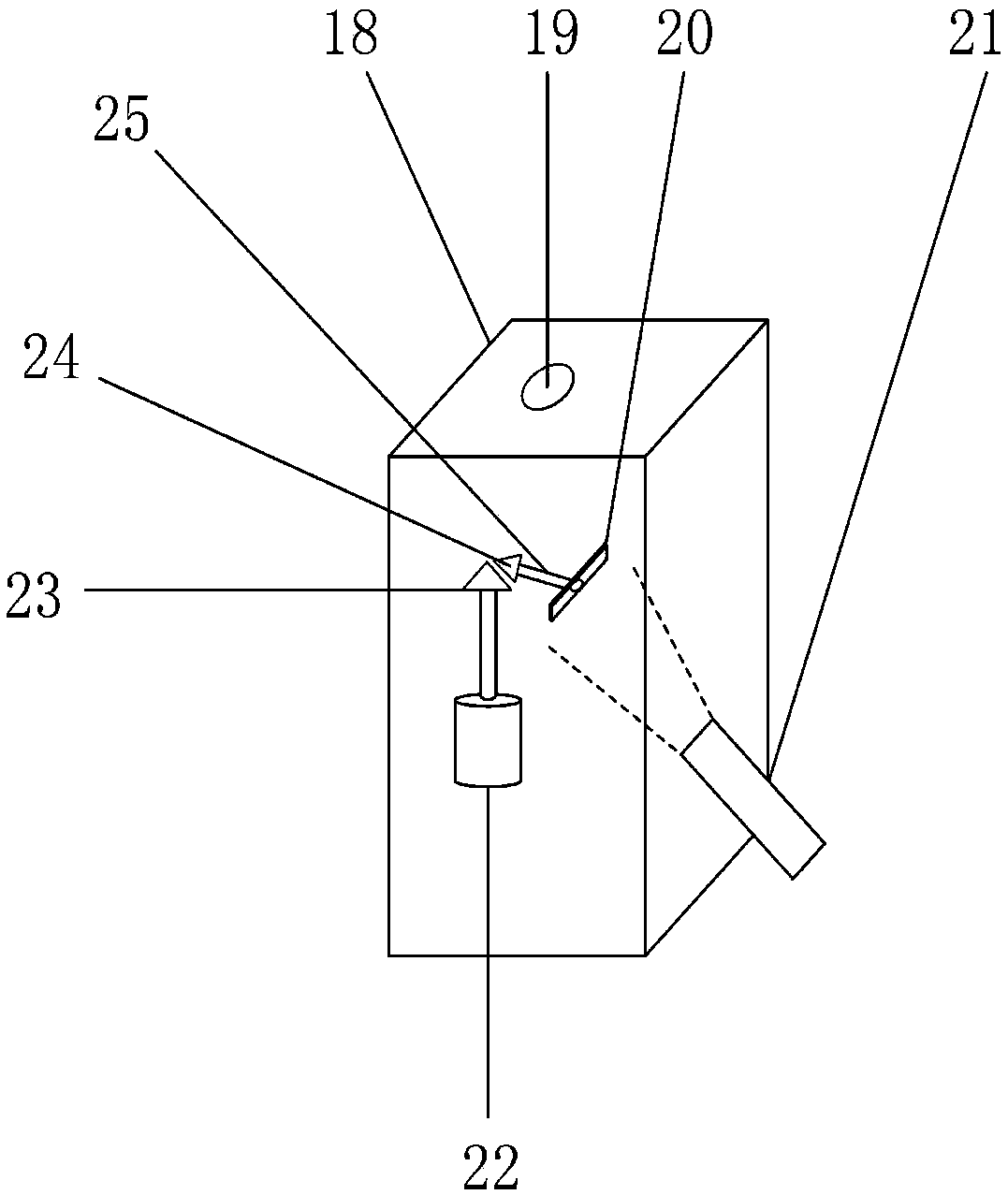

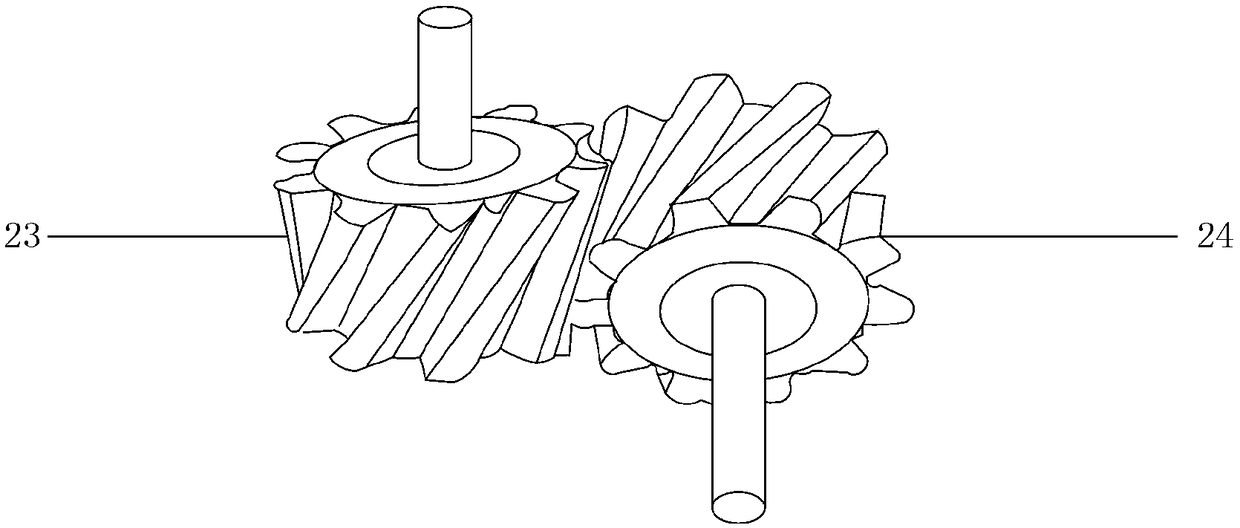

[0035] see Figures 1 to 6 , shows an automatic equipment for drying potato slices in an embodiment of the present invention, including a cleaning cylinder 1, a slicer 2, a slice table 3, a transfer plate 4, a mechanical arm 5, a water bath 6, and a transport table 7. Baking oven 8 and output table 9.

[0036] Such as figure 1 As shown, the cleaning tank 1 is connected to the slicing table 3. After the potatoes are put into the cleaning tank for automatic cleaning and peeling, the outlet of the cleaning tank enters the entrance of the slicer 2 for slicing. The slicer 2 is installed on the On the slicing table 3 and connected to the cleaning cylinder 1, put the transfer plate 4 on the slicing table 3, make the potato slices from the outlet of the slicer 2 slide down on the transfer plate 4, and spread the potato slices o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com