Device and method for leak plugging of heating pipe network

A heating pipe network and heating pipe technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of long construction time, shorten construction time, have strong linkage, and reduce the risk of being scalded. the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Other objects and advantages of the present invention will become clear by explaining the following preferred embodiments of the present application.

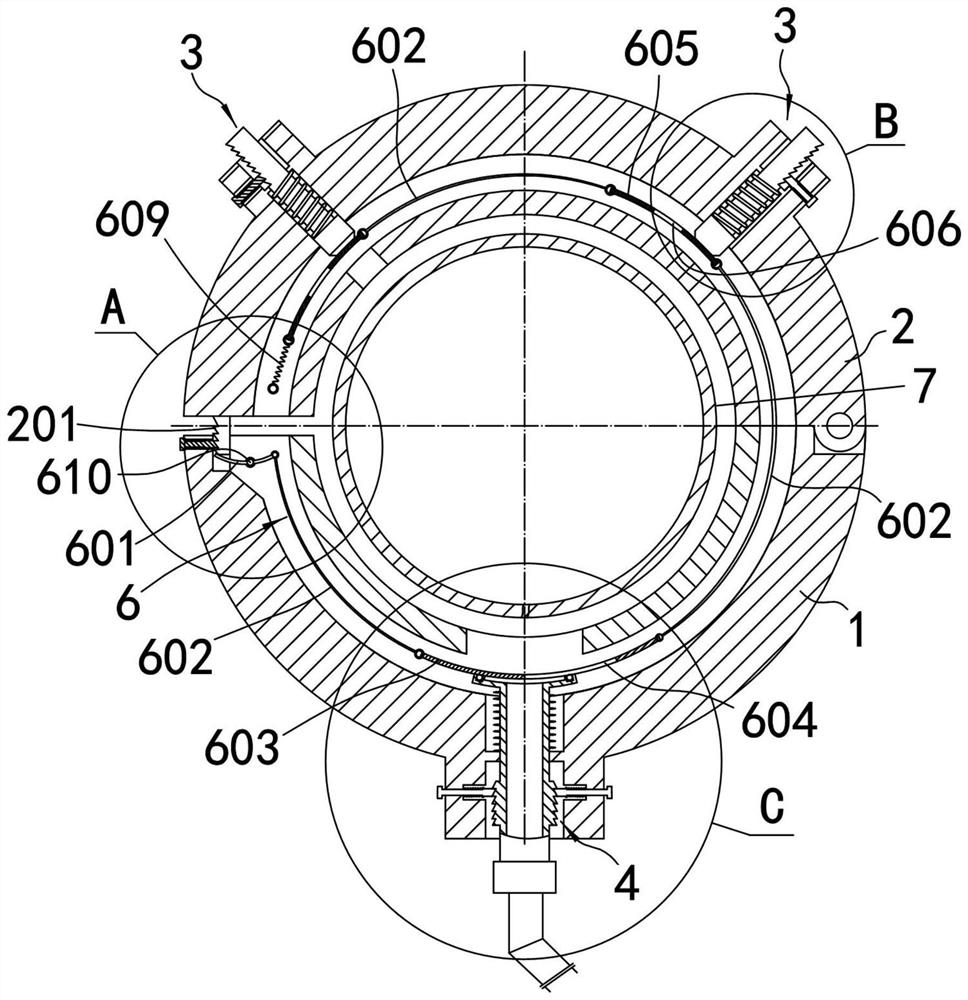

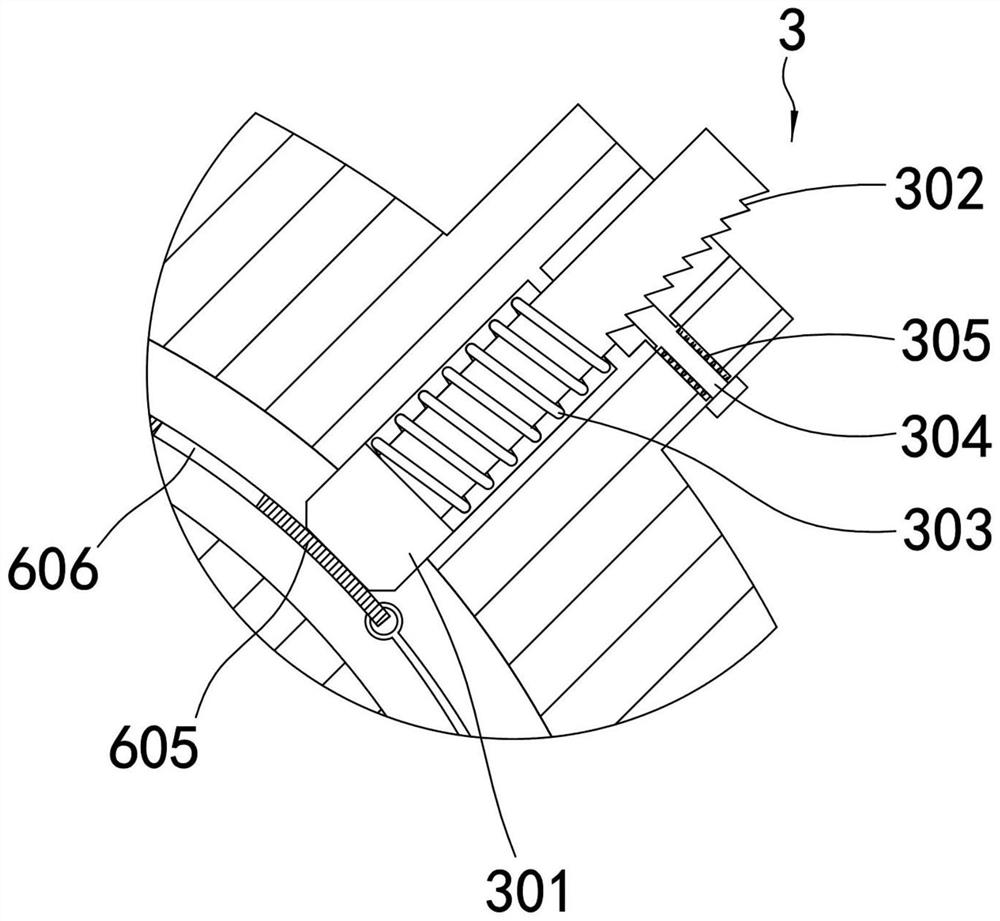

[0062] refer to Figure 1 to Figure 10 As shown, a leak-stopping device for a heating pipe network includes an annular body, a pressing unit 3 , a sealing unit 4 and a trigger unit 6 . The leak plugging device can quickly plug leaks, shorten construction time, and reduce the risk of construction personnel being scalded.

[0063] Such as figure 1 As shown, the ring body includes a first half ring 1 and a second half ring 2 . The first end of the first half ring 1 is pivotally connected to the first end of the second half ring 2 . The first half-ring 1 and the second half-ring 2 can be rotated to an open state, so that the leaking heat supply pipeline 7 is conveniently put into the cavity in the ring body. The second end of the second half-ring 2 is formed with a locking trigger portion 201 extending toward the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com