Chemical waste liquid purification treatment device integrating neutralization-precipitation-biomass treatment

A technology of biomass treatment and purification treatment, which is applied in the direction of sedimentation treatment, biological water/sewage treatment, neutralization water/sewage treatment, etc. It can solve the problems of inability to deal with heavy metal ions and the inability to adjust the pH of wastewater, so as to prevent microbial pollution, Effect of increasing processing capacity and increasing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

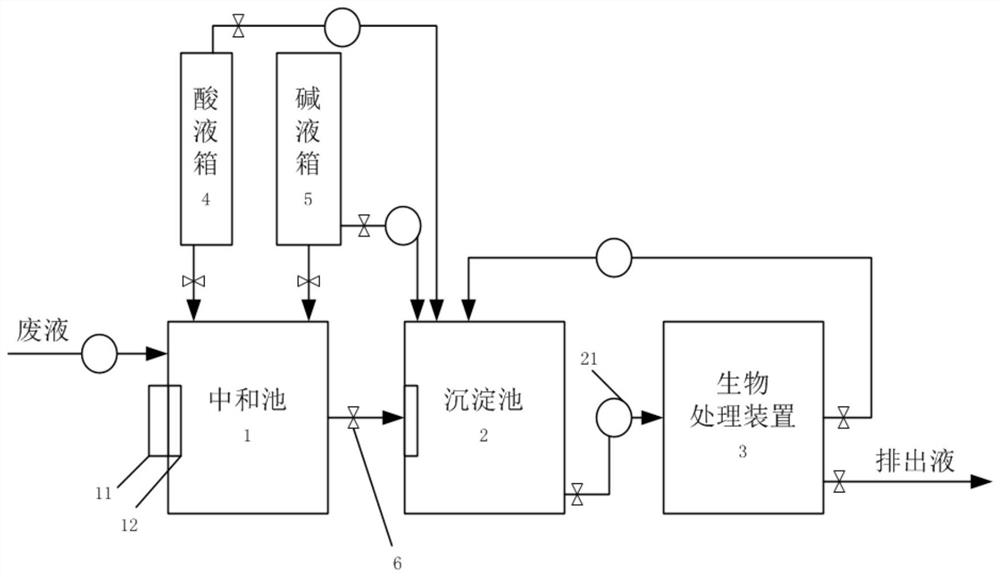

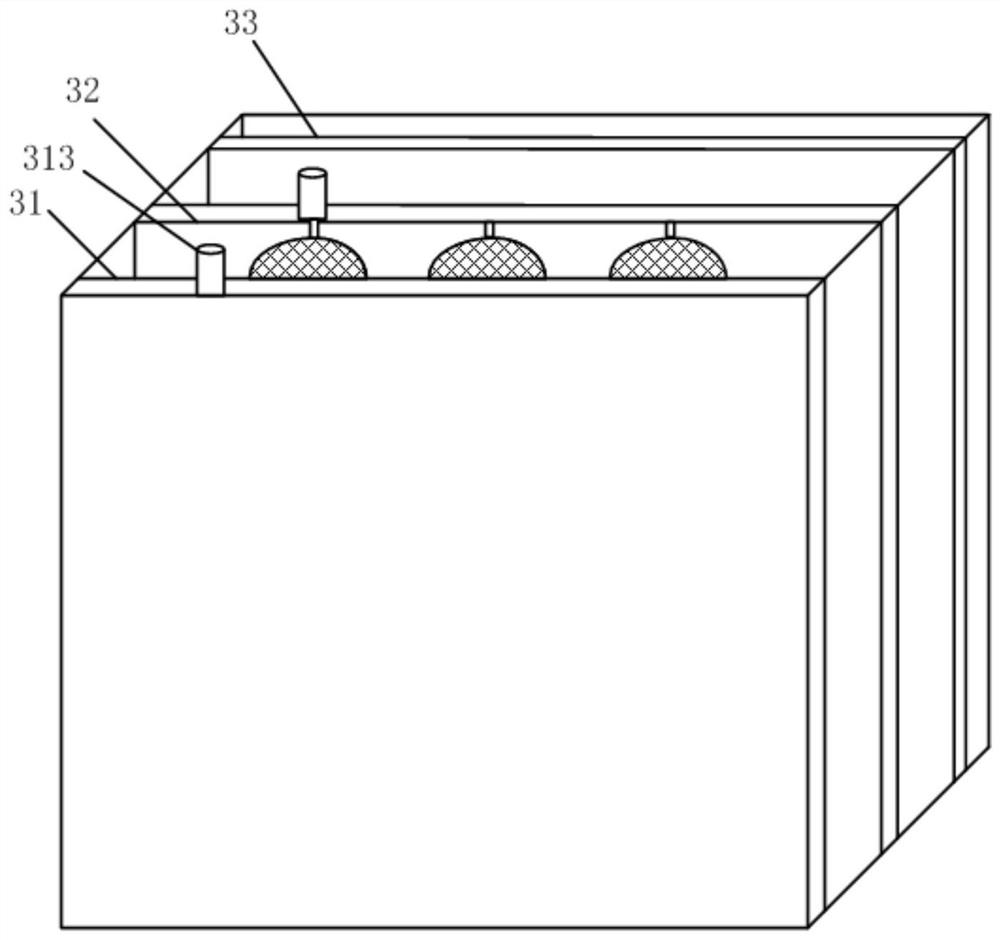

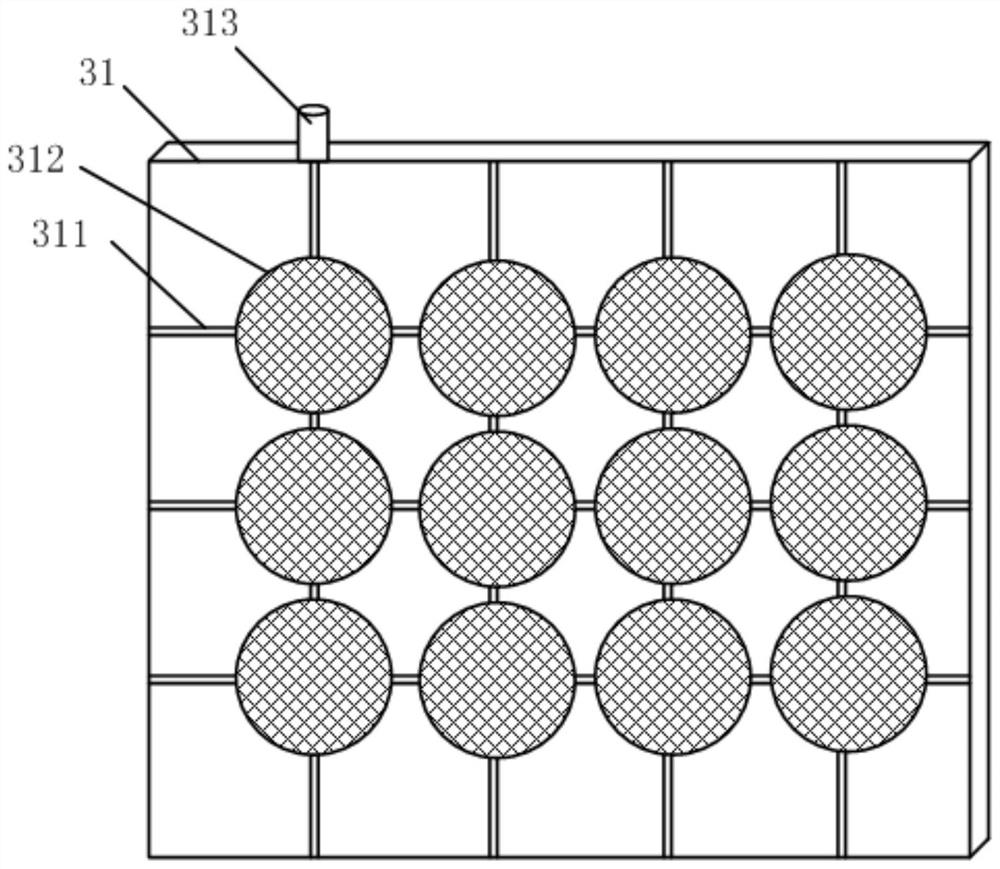

Embodiment 1

[0032] A chemical waste liquid purification treatment device integrating neutralization-precipitation-biomass treatment, see Figure 1-2 , including a neutralization tank 1, a sedimentation tank 2 and a biological treatment device 3 which are connected in sequence through pipelines. The neutralization tank 1 is provided with a waste water inlet, which is used to feed chemical waste liquid, which can be acid liquid, alkali Common types of chemical waste liquids such as liquid, organic solution, heavy metal ion solution, chemical waste residue liquid, etc. If the viscosity of the chemical waste liquid is high, a waste liquid lifting pump can be installed at the waste water inlet, and the waste liquid can be lifted by the power of the waste liquid lifting pump. Inject into neutralization pool 1. The neutralization tank 1 is connected with an acid solution tank 4 and an alkali solution tank 5 through pipelines, and the acid solution tank 4 is used to hold acid solutions, such as h...

Embodiment 2

[0040] A chemical waste liquid purification treatment device integrating neutralization-precipitation-biomass treatment, basically the same structure as in Example 1, the difference is:

[0041] In order to improve the adsorption and precipitation function of the filter cake 312 and the function of loading biomass, the filter cake 312 is inlaid with a plurality of load balls 3121, and the load balls 3121 can be glass balls, activated carbon balls or zeolite molecular sieve balls, honeycomb balls, or polymer resin The balls, the surfaces of these loading balls 3121 are provided with a plurality of micropores or the surface is matte, and the micropores or gaps on the matte surface can help sedimentation and biomass accumulation.

Embodiment 3

[0043] A chemical waste liquid purification treatment device integrating neutralization-precipitation-biomass treatment, basically the same structure as in Example 1, the difference is:

[0044] In order to control the flow, between the neutralization tank 1 and the acid tank 4, between the neutralization tank 1 and the lye tank 5, between the neutralization tank 1 and the sedimentation tank 2, the bottom of the sedimentation tank 2 or the bottom of the side wall (not provided The position of the circulating water inlet) and the biological treatment device 3, between the biological treatment device 3 and the circulating water inlet, and the pipeline of the liquid outlet of the biological treatment device 3 are all provided with a valve 6. The water flow is controlled by valve 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com