Height localization focused ultrasonic-assisted electromachining device and method

A technology focusing on ultrasonic waves and processing devices, applied in electric processing equipment, accessory devices, metal processing equipment, etc., can solve the problems that the auxiliary effect of ultrasonic waves cannot be well reflected, the length of the vibrator cannot be set arbitrarily, and the efficiency of ultrasonic waves is reduced. Achieve the effects of quantity reduction, high energy utilization rate and reduction of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

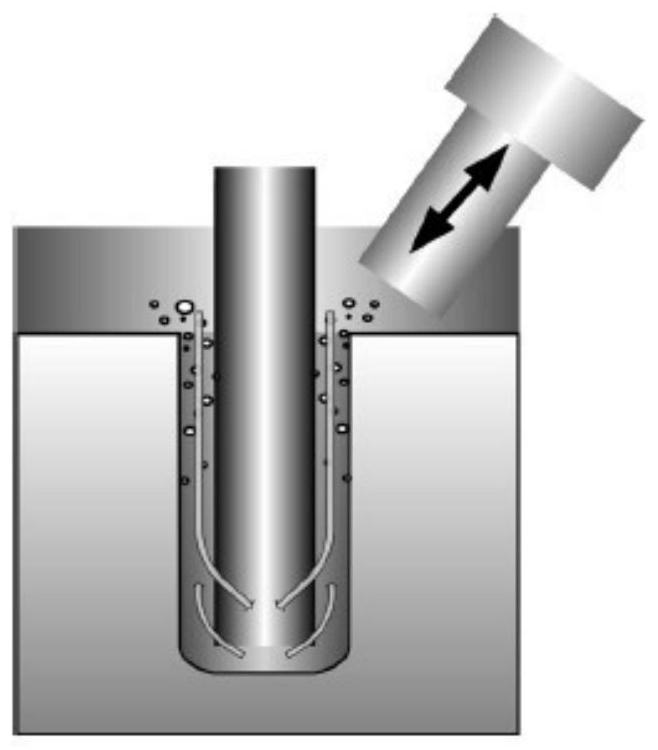

[0038] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0039] see Figure 4-Figure 6 , the present embodiment discloses a highly localized focused ultrasonic assisted electric machining device, including a mount 1 arranged on the machine tool spindle (not shown in the figure), and a mount 1 arranged on the mount 1 for electrically conducting workpieces. The electromachining mechanism of processing and the ultrasonic auxiliary mechanism for auxiliary electromachining; The machine tool spindle and the mounting seat 1 maintain a relatively static positional relationship, and the machine tool spindle is a part on the processing machine tool, and the machine tool spindle can be in the Z axis ( vertical) movement.

[0040] see Figure 4-Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap