Preparation and use method of manganese dioxide catalyst for catalytic oxidation of toluene

A manganese dioxide, catalytic oxidation technology, applied to metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Control and other issues to achieve the effect of preventing agglomeration, simple steps, and strong high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

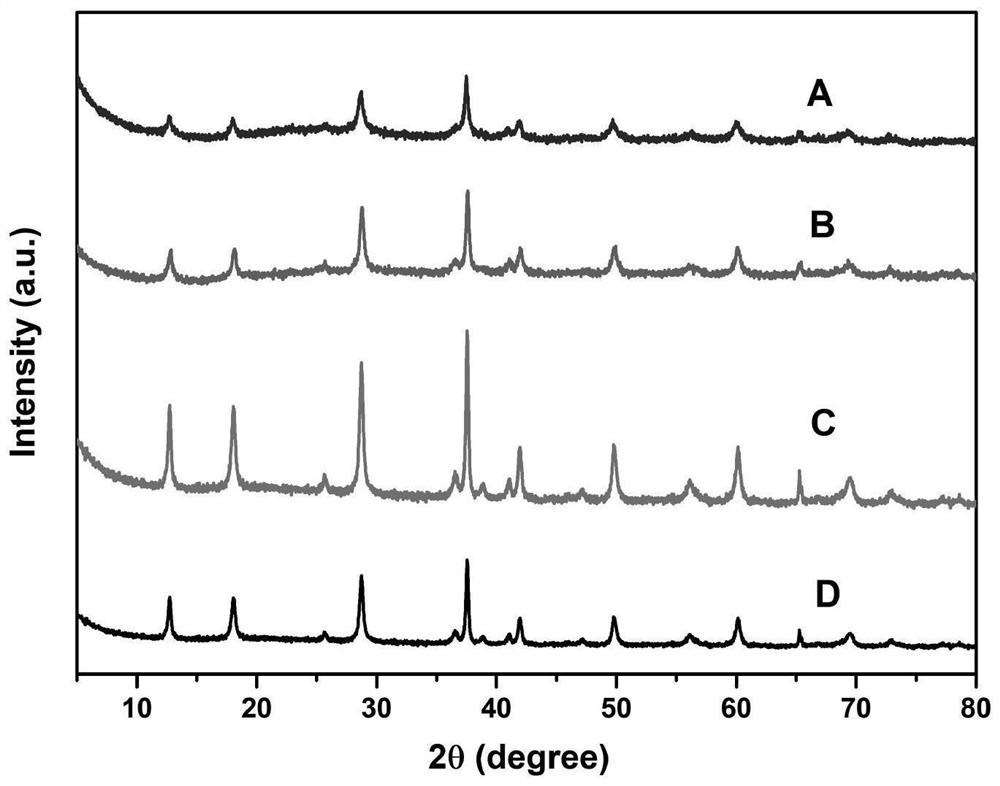

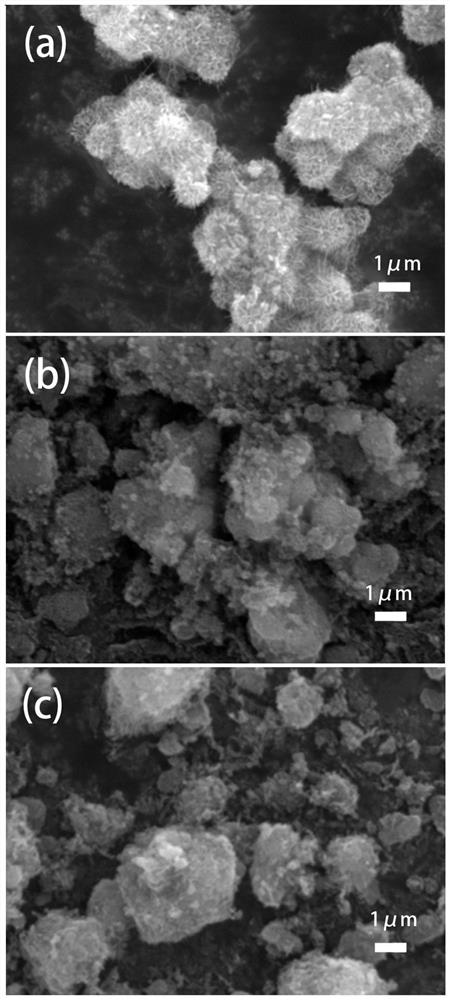

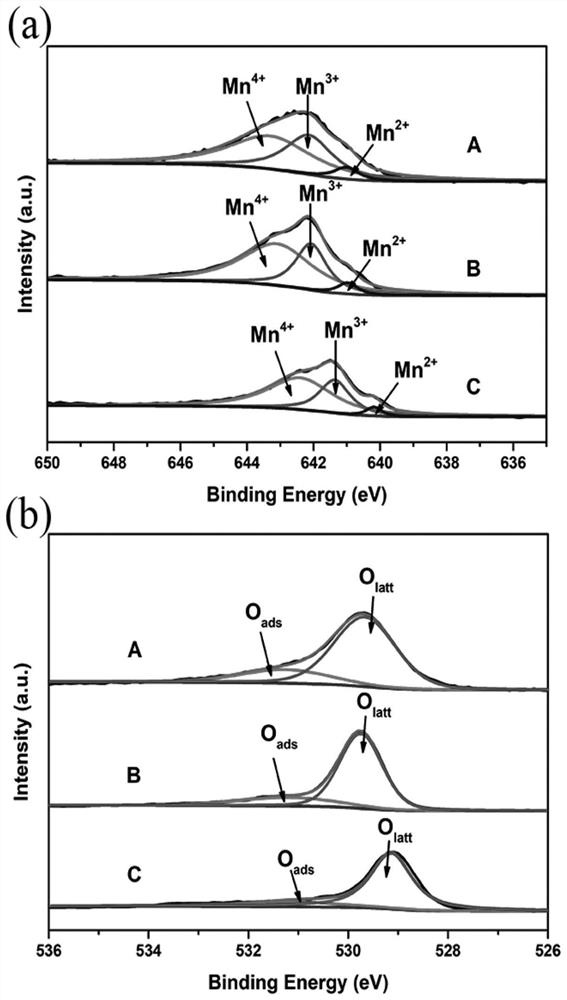

Embodiment 1

[0041] (1) 20mL concentration of 0.20mol / L potassium hydroxide aqueous solution and 20mL concentration of 0.10mol / L potassium permanganate aqueous solution are mixed uniformly at room temperature, and then added dropwise to a volume of 20mL concentration of 1.00mol / L n-butanol aqueous solution, and the temperature is raised to Continue to stir at 60°C for 30 minutes. After the reaction is completed, the product is suction-filtered and washed with deionized water, and the resulting filter cake is vacuum-dried at 60°C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100nm;

[0042] (2) Add 2 mmol of the precursor to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, then add 20 mL of 0.05 mol / L ethylenediaminetetraacetic acid disodium salt solution under stirring, Ultrasonic treatment for another 30 minutes, then continue to add 60 mL of 0.10 mol / L potassium permanganate aqueou...

Embodiment 2

[0045] (1) Mix 20 mL of 0.10 mol / L urea aqueous solution and 20 mL of 0.10 mol / L potassium permanganate aqueous solution at room temperature, and then add dropwise to 20 mL of 1.00 mol / L ethanol aqueous solution, heat up to 60°C and continue stirring After 30 minutes, the product was suction filtered and deionized water washed, and the resulting filter cake was vacuum-dried at 60°C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100 nm;

[0046] (2) Add 2 mmol of the precursor to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, then add 20 mL of 0.05 mol / L ethylenediaminetetraacetic acid disodium salt solution under stirring, Ultrasonic treatment for another 30 minutes, then continue to add 60 mL of 0.10 mol / L potassium permanganate aqueous solution dropwise to the above liquid under stirring, continue stirring for 60 minutes at room temperature after the dropwise addition...

Embodiment 3

[0049] (1) 20mL concentration of 0.20mol / L sodium hydroxide aqueous solution and 20mL concentration of 0.10mol / L potassium permanganate aqueous solution are mixed uniformly at room temperature, and then added dropwise to a volume of 20mL concentration of 1.00mol / L n-butanol aqueous solution, and the temperature is raised to Continue to stir at 60°C for 30 minutes. After the reaction is completed, the product is suction-filtered and washed with deionized water, and the resulting filter cake is vacuum-dried at 60°C to obtain a low-crystallinity spherical manganese dioxide precursor with an average particle size of less than 100nm;

[0050] (2) Add 2 mmol of the precursor to 20 mL of manganese sulfate solution with a concentration of 0.10 mol / L to form a dispersion, then add 20 mL of 0.05 mol / L ethylenediaminetetraacetic acid disodium salt solution under stirring, Ultrasonic treatment for another 30 minutes, and then continue to add 60 mL of 0.10 mol / L sodium permanganate aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com