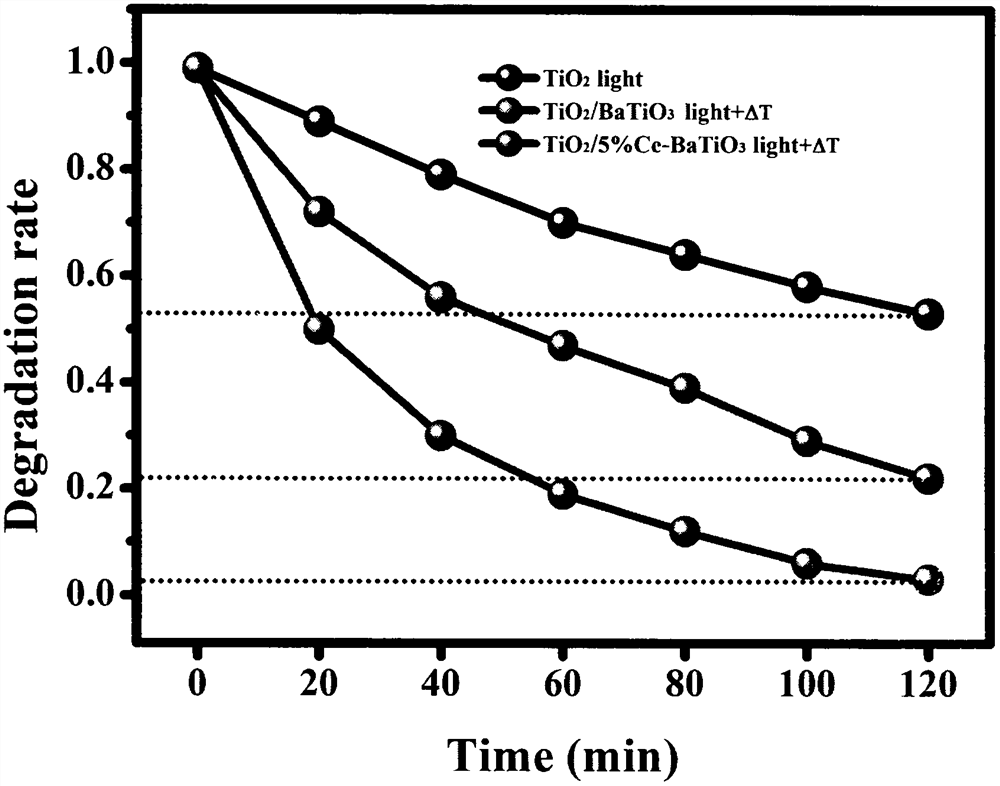

Preparation method of TiO2/Ce-BaTiO3 composite thin film material for degrading rhodamine B through photoelectrocatalysis

A ce-batio3, composite thin film technology, applied in the field of photoelectric catalytic thin film material preparation, can solve the problems of reduced conduction band, unsatisfactory visible light utilization efficiency, etc., achieves simple and easy operation of preparation method, widened visible light absorption range, and overall cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of TiO for photoelectrocatalytic degradation of Rhodamine B 2 / Ce-BaTiO 3 The preparation method of composite film material, comprises the steps:

[0019] (1) After mixing 10mL of dilute hydrochloric acid and deionized water at a ratio of 1:1, drop 0.5mL of tetrabutyl titanate solution into the mixture and stir evenly, and place the FTO conductive glass with the conductive side facing down. Put it into the liner of the reaction kettle that has been added with the reaction liquid, and after hydrothermal reaction at 160° C. for 18 hours, dry the reacted sample. Then put the sample in the crucible, transfer it to the muffle furnace for annealing treatment at 500°C for 2 hours, and obtain the rod-shaped TiO attached to the FTO conductive glass. 2 film.

[0020] (2) Add 5 mL of diethylene glycol, 5 mL of isopropanol, and 3 mL of tetrabutylammonium hydroxide solution into 5 mL of deionized water to prepare a mixed solvent, and dissolve 0.5 mM octahydrate barium hydr...

Embodiment 2

[0022] A kind of TiO for photoelectrocatalytic degradation of Rhodamine B 2 / Ce-BaTiO 3 The preparation method of composite film material, comprises the steps:

[0023] (1) After mixing 10mL of dilute hydrochloric acid and deionized water at a ratio of 1:1, drop 0.8mL of tetrabutyl titanate solution into the mixture and stir evenly, and place the FTO conductive glass with the conductive side facing down. Put it into the liner of the reaction kettle that has been added with the reaction liquid, and after hydrothermal reaction at 180° C. for 16 hours, dry the reacted sample. Then put the sample into the crucible, transfer it to the muffle furnace for annealing treatment at 550°C for 2 hours, and obtain the rod-shaped TiO attached to the FTO conductive glass. 2 film.

[0024] (2) Add 5mL diethylene glycol, 5mL isopropanol, and 3mL tetrabutylammonium hydroxide solution into 5mL deionized water to prepare a mixed solvent, and dissolve 0.5mM octahydrate barium hydroxide and 0.025...

Embodiment 3

[0026] A kind of TiO for photoelectrocatalytic degradation of Rhodamine B 2 / Ce-BaTiO 3 The preparation method of composite film material, comprises the steps:

[0027] (1) After mixing 10mL dilute hydrochloric acid and deionized water at a ratio of 1:1, drop 1.0mL tetrabutyl titanate solution into the mixture and stir evenly, and place the FTO conductive glass with the conductive side facing down. Put it into the liner of the reaction kettle that has been added with the reaction solution, and after hydrothermal reaction at 180°C for 20 hours, dry the reacted sample. Then put the sample into the crucible, transfer it to the muffle furnace for annealing treatment at 600°C for 2 hours, and obtain the rod-shaped TiO attached to the FTO conductive glass. 2 film.

[0028] (2) Add 5mL diethylene glycol, 5mL isopropanol, and 3mL tetrabutylammonium hydroxide solution into 5mL deionized water to prepare a mixed solvent, and dissolve 0.5mM octahydrate barium hydroxide and 0.01mM ceri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com