Granular flue gas denitration agent and preparation method thereof

A denitrification agent and granular technology, applied in the field of granular flue gas denitrification agent and its preparation, can solve the problems of pipeline corrosion and perforation, reduction of flue gas temperature, poor mixing effect, etc., so as to reduce production cost, prolong service life and improve The effect of blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

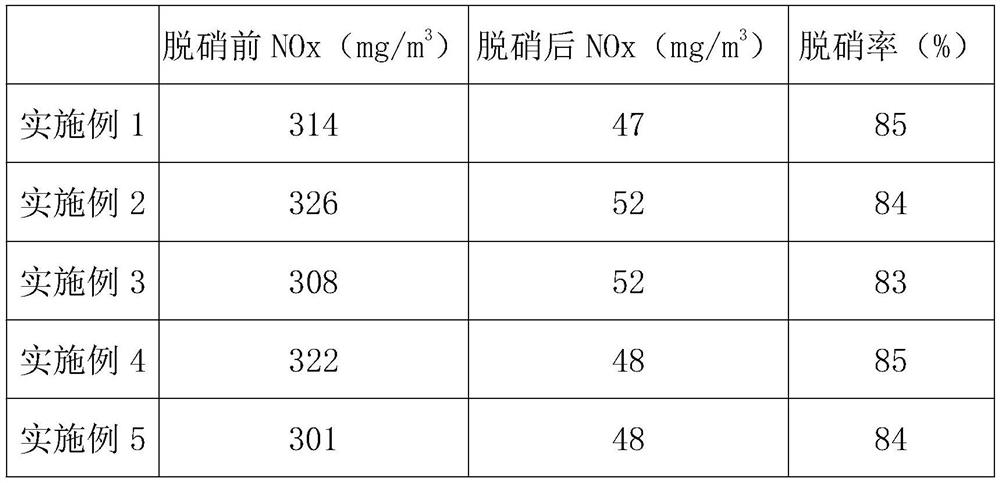

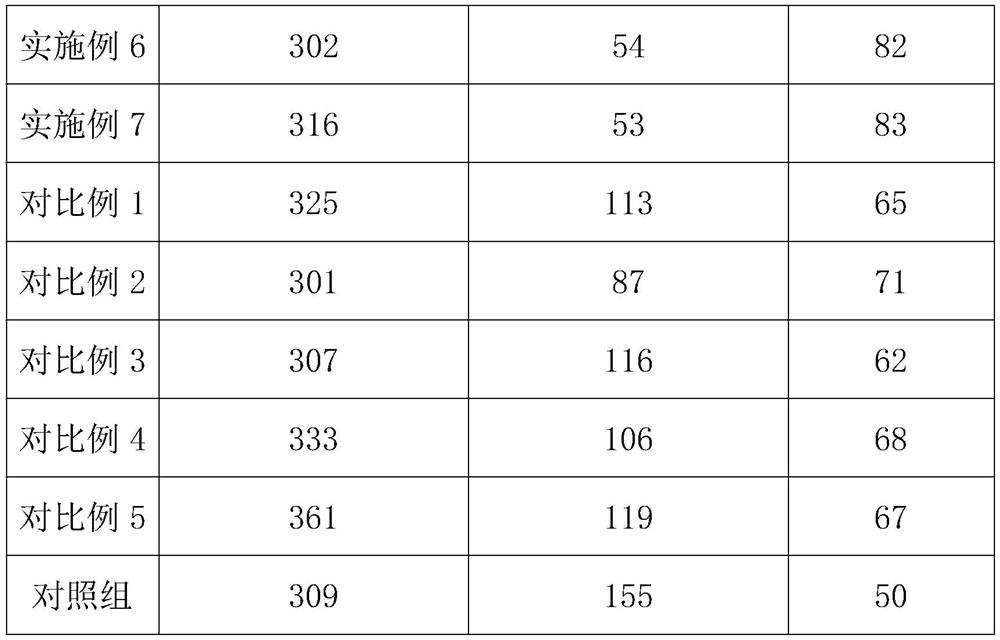

Examples

Embodiment 1

[0034] Polyethylene glycol is dissolved in water to prepare a polyethylene glycol aqueous solution with a mass concentration of 15%, which is coated on the surface of solid urea by spraying to form a polyethylene glycol aqueous solution coating layer, and then coated in the polyethylene glycol aqueous solution Coat the outer surface of the cladding layer with kaolin to form a kaolin cladding layer to obtain a granular flue gas denitrification agent with a particle size of 1.84 mm.

[0035] Wherein, polyethylene glycol aqueous solution and solid urea mass ratio are 0.004:1;

[0036] The mass ratio of kaolin to solid urea is 0.05:1.

Embodiment 2

[0038] Dissolve polyvinyl alcohol in water to prepare a polyvinyl alcohol aqueous solution with a mass concentration of 8%, and spray it on the surface of solid urea to form a polyvinyl alcohol aqueous solution coating layer, and then coat the outer surface of the polyvinyl alcohol aqueous solution coating layer Then coat the cement to form a cement coating layer to obtain a granular flue gas denitrification agent with a particle size of 0.86 mm.

[0039] Wherein, the mass ratio of polyvinyl alcohol aqueous solution to solid urea is 0.002:1;

[0040] The mass ratio of cement to solid urea is 0.048:1.

Embodiment 3

[0042] Dissolve triethylene glycol in water to prepare a triethylene glycol aqueous solution with a mass concentration of 22%, and spray it on the surface of solid urea to form a triethylene glycol aqueous solution coating layer, and then coat the outer surface of the triethylene glycol aqueous solution coating layer Then coat fly ash to form a fly ash coating layer to obtain a granular flue gas denitrification agent with a particle size of 2.81mm.

[0043] Wherein, the mass ratio of triethylene glycol aqueous solution to solid urea is 0.006:1;

[0044] The mass ratio of fly ash to solid urea is 0.052:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com