N-type battery structure and preparation method thereof

An N-type battery technology, applied in the field of solar cells, can solve the problems of unfavorable film passivation, rough textured surface, surface passivation and surface metal contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

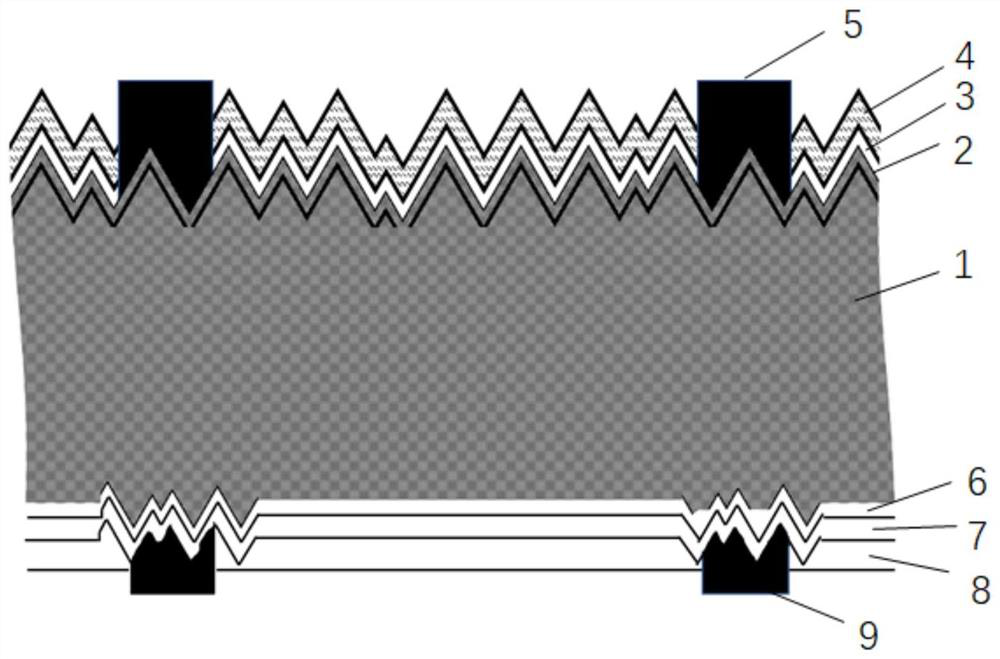

[0064] This embodiment provides an N-type battery structure (for a schematic diagram, see figure 1 ), comprising: an N-type silicon body material 1, a pn junction layer 2, a passivation layer 3, an anti-reflection layer 4 and a front electrode 5 located in sequence on the front side of the N-type silicon body material 1,

[0065] And a quantum tunneling layer 6, a P-doped polysilicon layer 7, a protection layer 8 and a metal gate line electrode 9 located on the back of the N-type silicon body material 1 in sequence;

[0066] Wherein, the front electrode 5 is in contact with the passivation layer 3 , and the metal gate line electrode 9 is in contact with the P-doped polysilicon layer 7 . The back side of the N-type silicon material is a selective textured structure in which part of the textured surface is partially polished. The position where the metal grid electrode contacts the N-type silicon material is the textured surface, and the non-contact position is the polished surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com