Smoke exhaust fireproof valve

A fire damper and valve body technology, which is applied in the direction of lift valves, valve details, valve devices, etc., can solve the problems of inability to achieve high-temperature flue gas fire prevention effects, easy air leakage areas at joints, and low sealing performance, so as to improve the fire prevention effect , improve service life and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

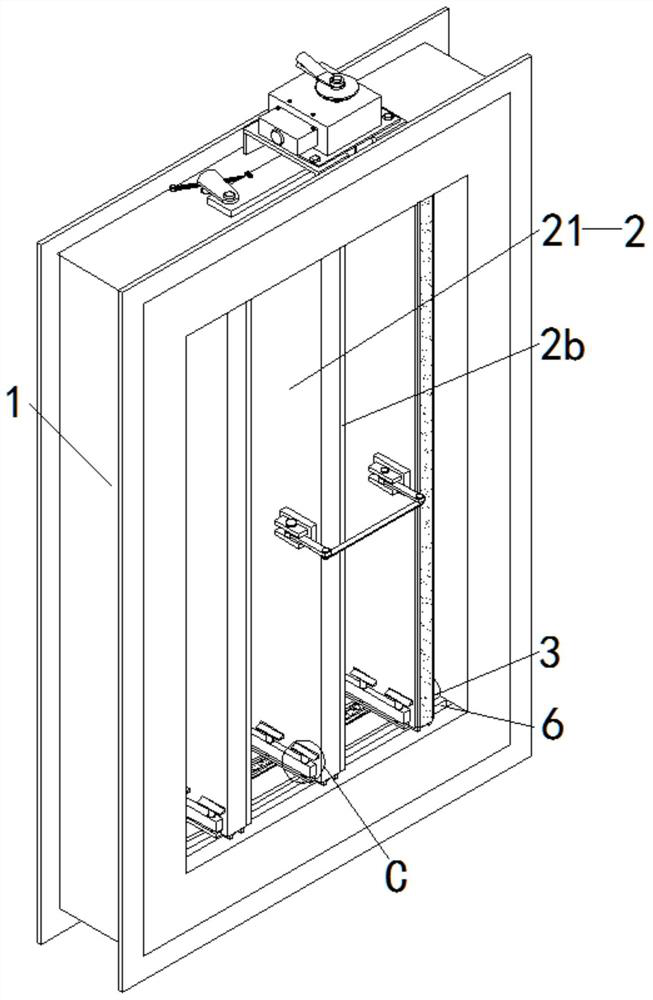

[0037] Attached below Figure 1-10 The present invention is further described with embodiment:

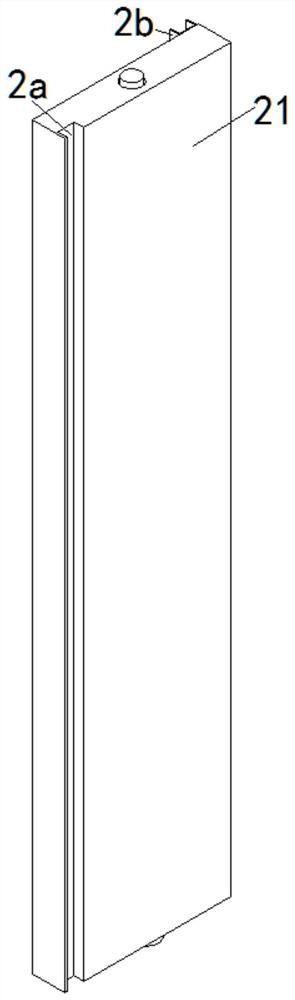

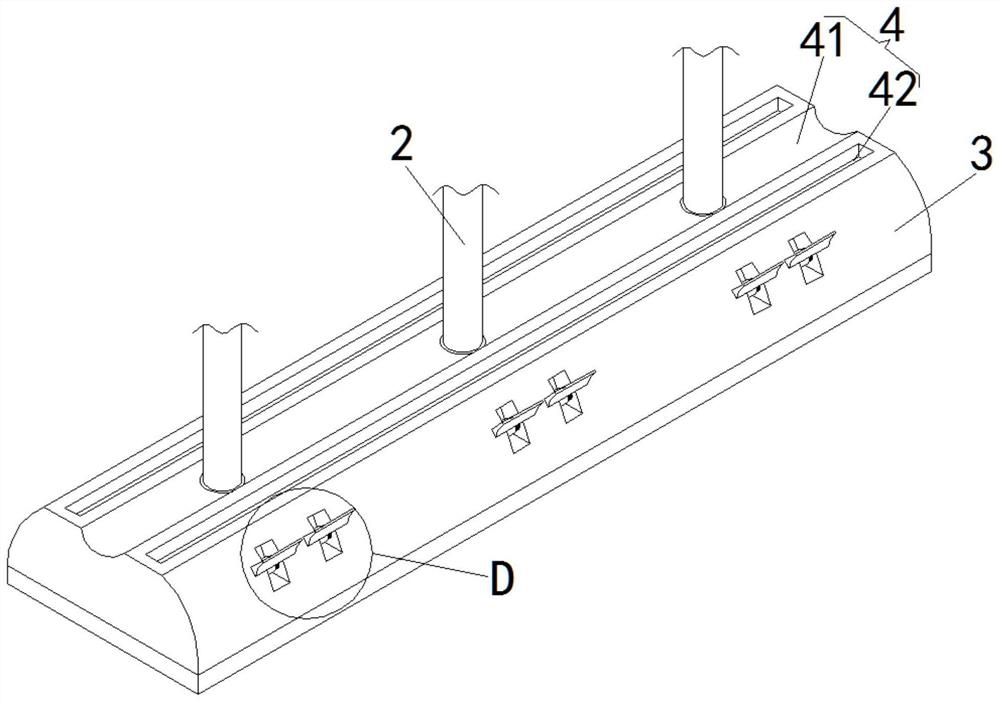

[0038] Such as figure 1 and figure 2 As shown, a smoke fire damper includes a valve body 1 and a fireproof blade assembly 2 arranged in the valve body 1, and also includes two sealing seats 3 oppositely arranged on the inner wall of the valve body 1, and the fireproof blade assembly 2 Set between two sealing seats 3, the sealing seat 3 is provided with a sealing groove 4, and the side of the fireproof blade assembly 2 close to the sealing seat 3 is provided with a telescopic seal 5 for inserting into the sealing groove 4, and the rigid The contact type closure is converted into a soft contact type closure, which can reduce the damage to the fireproof blade 21 itself during the closing process and improve the service life of the fireproof blade 21;

[0039] The fire-proof blade assembly 2 includes a plurality of fire-proof blades 21, and the fire-proof blades 21 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com