Construction method of solidified soil pile

A construction method and technology for solidifying soil, applied in soil protection, sheet pile wall, foundation structure engineering and other directions, can solve the problems of low soil friction, increase construction cost, reduce lateral friction of foundation soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

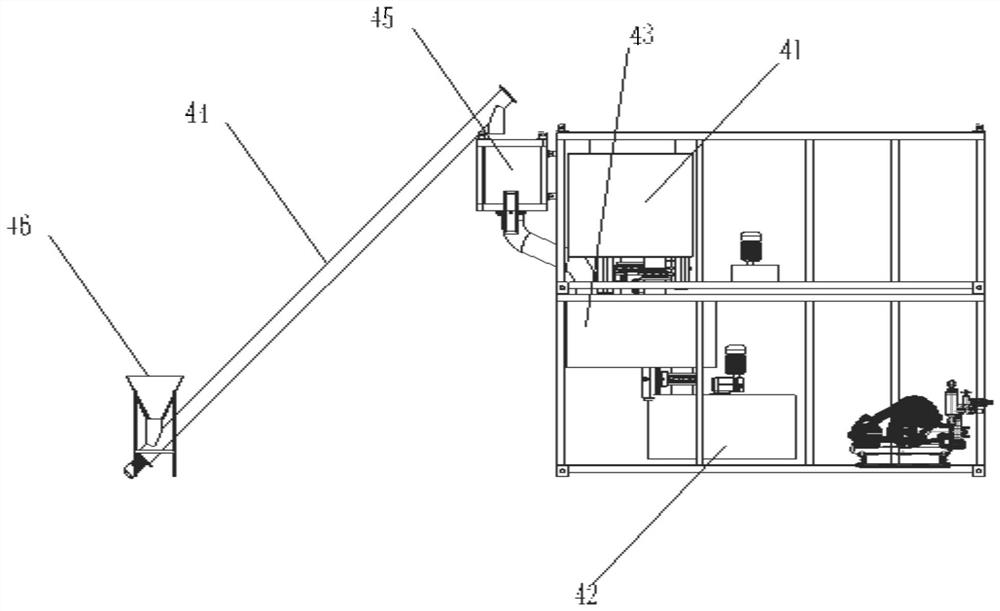

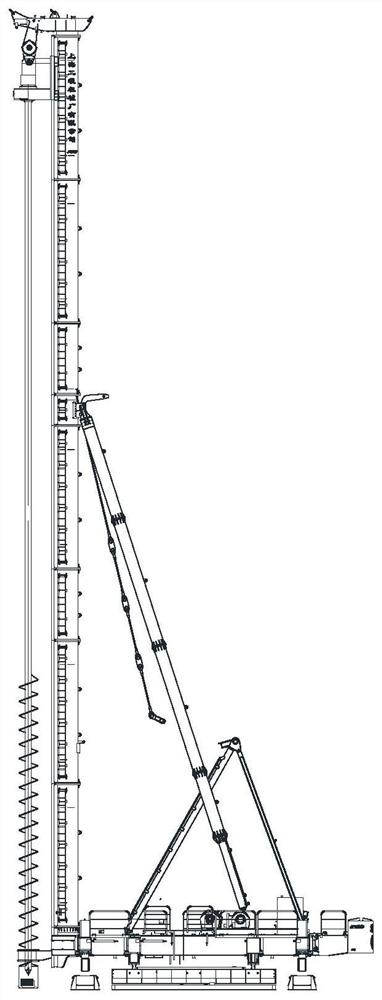

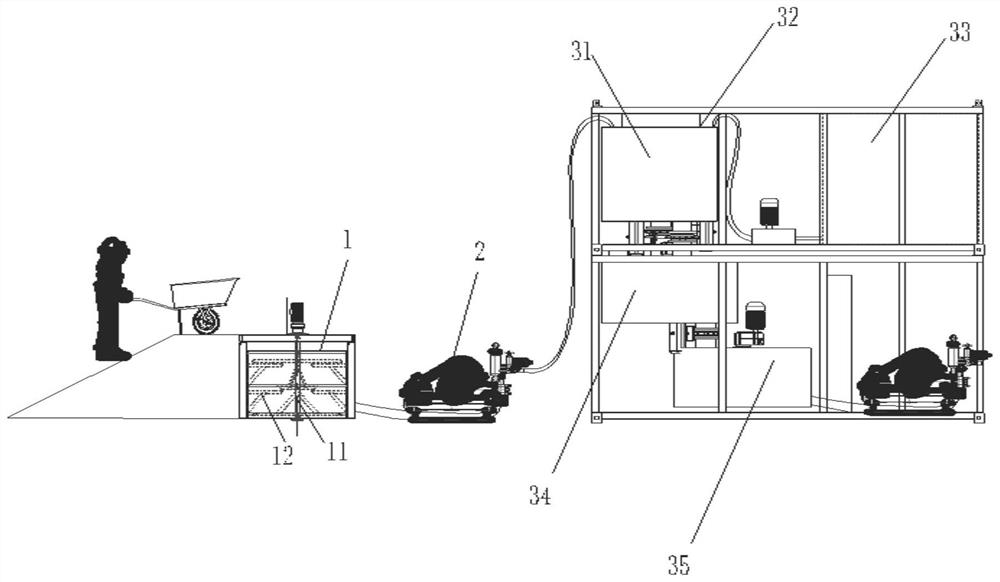

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0038] The solidified soil pile includes a pile hole, and a prefabricated pile is implanted in the pile hole, and the gap between the prefabricated pile and the pile hole is filled with solidified soil.

[0039] The solidified soil is a liquid solidified soil, and the fluid solidified soil is a mixture of a solidifying agent slurry and an undisturbed soil.

[0040] Add moist caking materials into the solidified soil, the main component of which is natural dihydrate gypsum with a chemical formula of CaSO4·2H2O. Natural dihydrate gypsum is also called air-hardening inorganic cementitious material. This kind of gypsum is lumpy or lumpy and has cohesiveness. It is directly mixed into the undisturbed soil, and it is not easy to stir and cannot be mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com